A kind of titanium nitride/polyaniline composite conductive anti-corrosion powder coating and preparation method thereof

A technology of composite conductive and powder coatings, which is applied in the direction of powder coatings, conductive coatings, anti-corrosion coatings, etc., and can solve problems such as electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

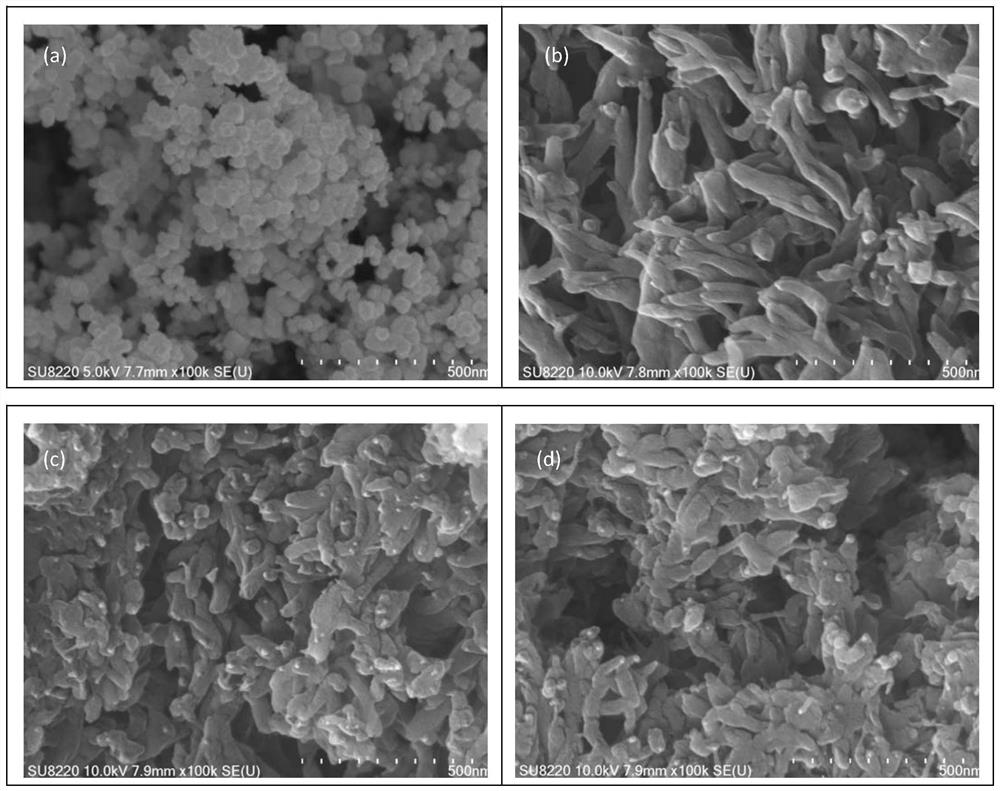

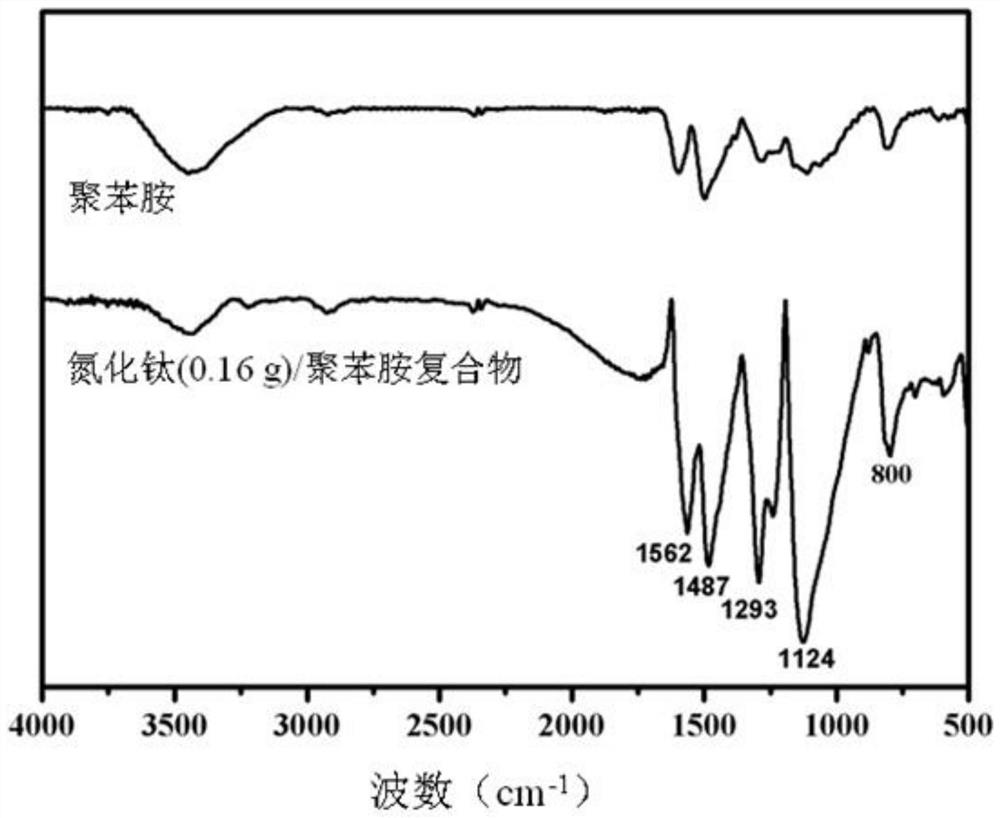

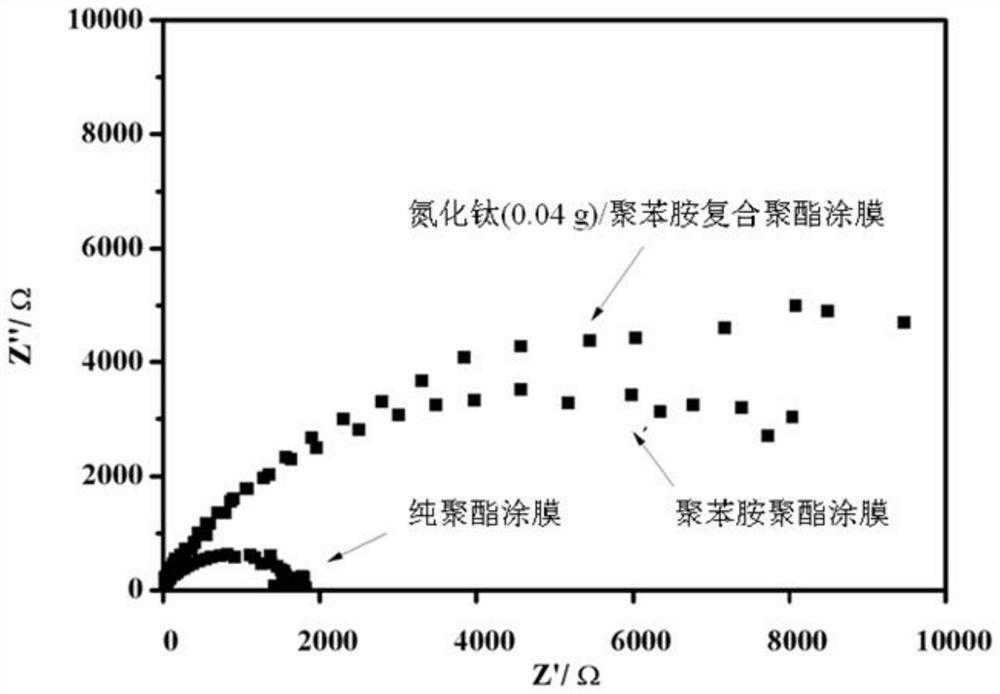

[0039] The invention discloses a preparation method of titanium nitride / polyaniline composite conductive anticorrosion powder coating, which comprises the preparation of conductive filler and the preparation of titanium nitride / polyaniline composite conductive anticorrosion powder coating.

[0040] Step 1: Preparation of conductive filler

[0041] (1) First, prepare a hydrochloric acid solution with a concentration of 1.0 mol / L; then, weigh titanium nitride, aniline, and hydrochloric acid according to the mass-volume ratio of titanium nitride, aniline, and hydrochloric acid solution in a ratio of 0.01 g: 0.23 g: 50 ml solution; mix the weighed titanium nitride and aniline into the hydrochloric acid solution, and carry out ultrasonic dispersion, so that the titanium nitride and aniline are uniformly mixed in the hydrochloric acid solution to obtain a titanium nitride-aniline-hydrochloric acid mixed solution;

[0042] (2) Weigh the ammonium persulfate and hydrochloric acid solut...

Embodiment 2

[0051] The invention discloses a preparation method of titanium nitride / polyaniline composite conductive anticorrosion powder coating, which comprises the preparation of conductive filler and the preparation of titanium nitride / polyaniline composite conductive anticorrosion powder coating.

[0052] Step 1: Preparation of conductive filler

[0053] (1) First, prepare a hydrochloric acid solution with a concentration of 1.0 mol / L; then, weigh titanium nitride, aniline and hydrochloric acid according to the mass volume ratio of titanium nitride, aniline and hydrochloric acid solution at a ratio of 0.04 g: 0.23 g: 50 ml solution; mix the weighed titanium nitride and aniline into the hydrochloric acid solution, and carry out ultrasonic dispersion, so that the titanium nitride and aniline are uniformly mixed in the hydrochloric acid solution to obtain a titanium nitride-aniline-hydrochloric acid mixed solution;

[0054] (2) Weigh the ammonium persulfate and hydrochloric acid solutio...

Embodiment 3

[0061] The invention discloses a preparation method of titanium nitride / polyaniline composite conductive anticorrosion powder coating, which comprises the preparation of conductive filler and the preparation of titanium nitride / polyaniline composite conductive anticorrosion powder coating.

[0062] Step 1: Preparation of conductive filler

[0063] (1) First, prepare a hydrochloric acid solution with a concentration of 1.0 mol / L; then, weigh titanium nitride, aniline and hydrochloric acid according to the mass volume ratio of titanium nitride, aniline and hydrochloric acid solution at a ratio of 0.08 g: 0.23 g: 50 ml solution; mix the weighed titanium nitride and aniline into the hydrochloric acid solution, and carry out ultrasonic dispersion, so that the titanium nitride and aniline are uniformly mixed in the hydrochloric acid solution to obtain a titanium nitride-aniline-hydrochloric acid mixed solution;

[0064] (2) Weigh the ammonium persulfate and hydrochloric acid solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com