Antibacterial glass fiber air filter paper and preparation method thereof

A technology of air filter paper and glass fiber, which is applied in the field of air filtration and purification, can solve the problems of poor antibacterial and antibacterial effects of glass fiber air filter paper, general air filtration effect, and difficulty in preventing bacterial reproduction, etc., so as to improve overall economic benefits and improve air quality. Filtration effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

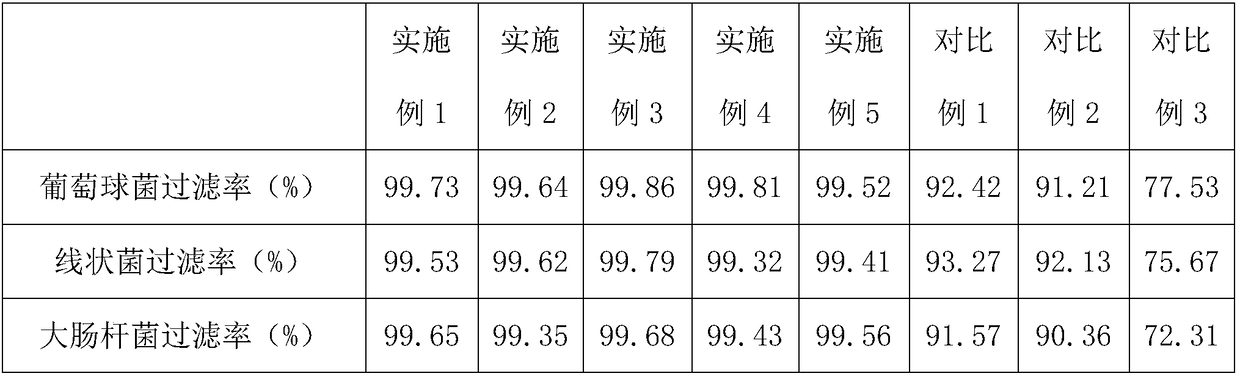

Examples

Embodiment 1

[0021] An antibacterial glass fiber air filter paper, comprising the following raw materials in parts by weight: 80 parts of alkali-free glass microfibers, 10 parts of polytetrafluoroethylene, 15 parts of dimethyl sulfoxide, 3 parts of caproyl acetaldehyde, 4-isopropyl 2 parts of hydroxy-2-hydroxy-cycloheptyl-2,4,6 trien-1-one, 2 parts of methyl n-nonyl acetaldehyde, 0.3 parts of antibacterial agent, and 3 parts of binder.

[0022] Wherein, the antibacterial agent is nano silver ion.

[0023] Wherein, the binder is ethyl cyanoacrylate.

[0024] In the present embodiment, the preparation method of described antibacterial glass fiber air filter paper, the steps are as follows:

[0025] 1) After pulverizing the alkali-free glass microfibers and passing through a 200-mesh sieve, add them to a beater, add polytetrafluoroethylene, dimethyl sulfoxide and clear water 20 times the total weight, adjust the pH value to 4, and perform beating and dispersion to obtain pulp suspension;

...

Embodiment 2

[0030] An antibacterial glass fiber air filter paper, comprising the following raw materials in parts by weight: 85 parts of alkali-free glass microfibers, 11 parts of polytetrafluoroethylene, 16 parts of dimethyl sulfoxide, 4.5 parts of caproyl acetaldehyde, 4-isopropyl 2.8 parts of methyl-2-hydroxy-cycloheptyl-2,4,6-trien-1-one, 2.8 parts of methyl n-nonyl acetaldehyde, 0.45 parts of antibacterial agent, and 4.5 parts of binder.

[0031] Wherein, the antibacterial agent is nano silver ion.

[0032] Wherein, the binder is ethyl cyanoacrylate.

[0033] In the present embodiment, the preparation method of described antibacterial glass fiber air filter paper, the steps are as follows:

[0034] 1) After pulverizing the alkali-free glass microfibers and passing through a 260-mesh sieve, add them to a beater, add polytetrafluoroethylene, dimethyl sulfoxide, and clear water 22 times the total weight, adjust the pH value to 4.5, and perform beating and dispersion to obtain pulp sus...

Embodiment 3

[0039] An antibacterial glass fiber air filter paper, comprising the following raw materials in parts by weight: 90 parts of alkali-free glass microfibers, 12 parts of polytetrafluoroethylene, 18 parts of dimethyl sulfoxide, 4 parts of capryl acetaldehyde, 4-isopropyl 2.5 parts of methyl-2-hydroxy-cycloheptyl-2,4,6-trien-1-one, 2.5 parts of methyl n-nonyl acetaldehyde, 0.4 parts of antibacterial agent, and 4 parts of binder.

[0040] Wherein, the antibacterial agent is nano silver ion.

[0041] Wherein, the binder is ethyl cyanoacrylate.

[0042] In the present embodiment, the preparation method of described antibacterial glass fiber air filter paper, the steps are as follows:

[0043] 1) After pulverizing the alkali-free glass microfibers and passing through a 260-mesh sieve, add them to a beater, add polytetrafluoroethylene, dimethyl sulfoxide, and clear water 22 times the total weight, adjust the pH value to 4.5, and perform beating and dispersion to obtain pulp suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com