Copper complex catalyst for acetylene hydrochlorination reaction and preparation method thereof

A technology for acetylene hydrochlorination and copper complexes, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, catalytic reactions, etc. High cost, difficulty in industrial production, etc., to achieve the effect of low price, low preparation cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The specific operation steps are as follows:

[0037] (1) Dissolve the copper salt and the organic phosphoric acid ligand in water or ethanol, and mix them uniformly to obtain a mixed solution; the copper salt includes one of copper chloride, copper nitrate, copper phosphate, copper acetate, copper sulfate or Various; organic phosphoric acid-containing ligands include: one or more of hydroxyethylidene diphosphonic acid, aminotrimethylene phosphonic acid, and ethylenediamine tetramethylene phosphonic acid.

[0038] (2) After mixing the mixed solution and the carrier evenly, impregnate at 20-80°C for 24 hours; the carrier is activated carbon with a specific surface area of 500-1500m 2 / g, the mass fraction of ash is less than or equal to 6.0%, including coconut shell charcoal, wood charcoal, or coal-based charcoal.

[0039] (3) drying at 60-120° C. for 24 hours to obtain the copper complex catalyst. The mass fraction of the organic phosphoric acid-containing ligand in...

Embodiment 2

[0042] (1) Dissolve copper chloride dihydrate and aminotrimethylene phosphonic acid (ATMP) in 15 ml of deionized water, stir the mixture for 30 min to obtain a uniform blue solution, and obtain a mixed solution.

[0043] (2) Add the mixed solution dropwise to 3.0 g of coconut shell activated carbon, mix well, stir at 20°C, and impregnate for 24 hours.

[0044] (3) Dry at 80° C. for 24 hours to obtain the copper complex catalyst.

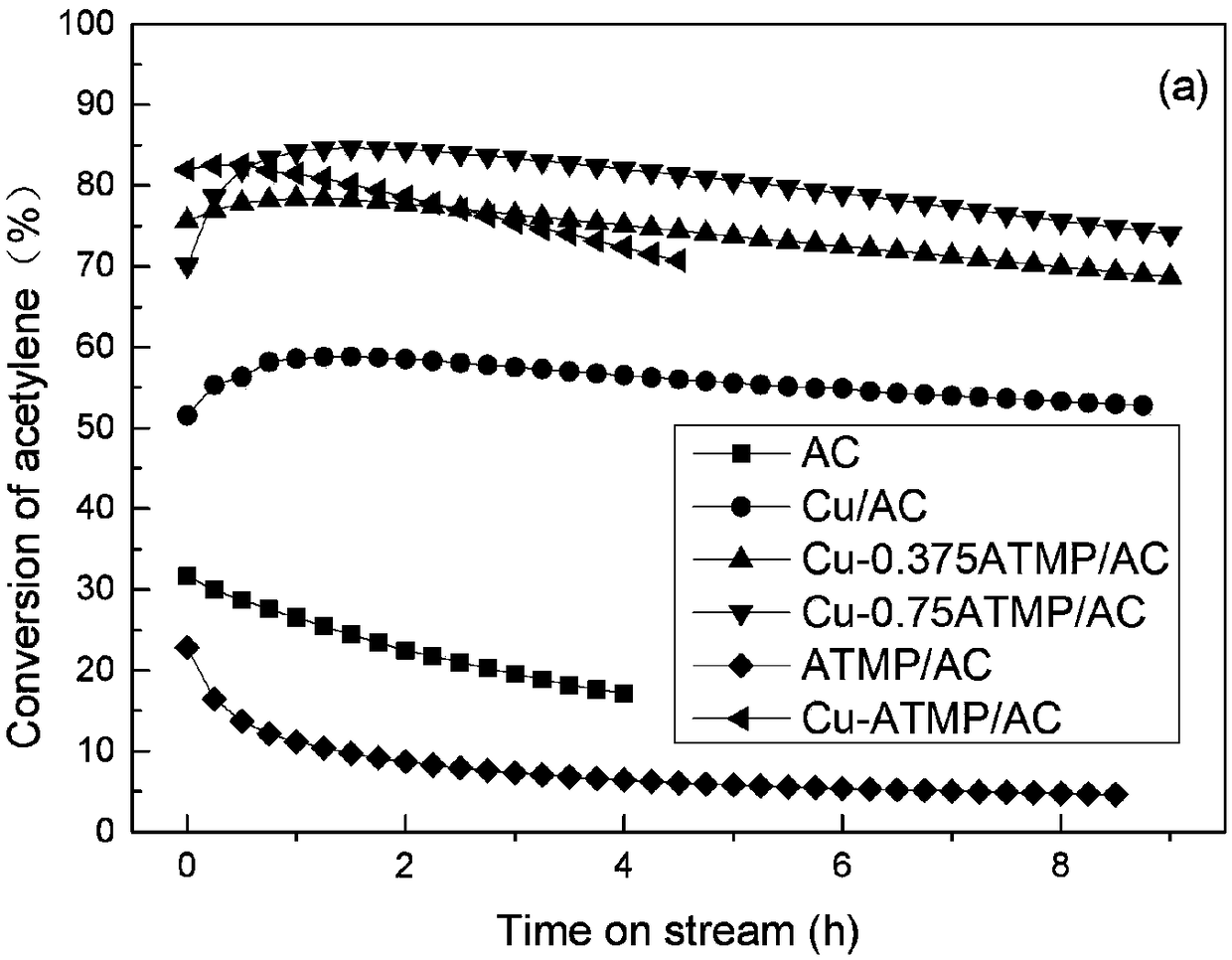

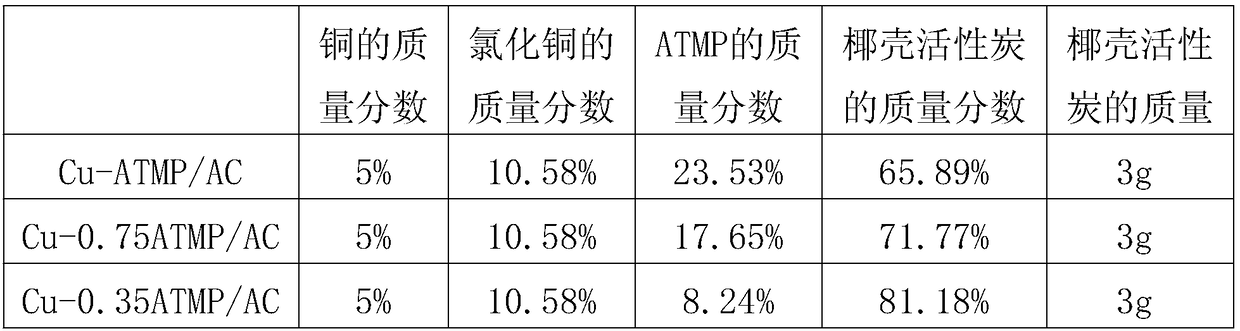

[0045] adjust CuCl 2 And the molar ratio of ATMP, its molar ratio is respectively 1:1, 1:0.75, 1:0.35, and the copper complex catalyst that makes is named as Cu-ATMP / AC, Cu-0.75ATMP / AC, Cu-0.35ATMP respectively / AC. The mass fraction of copper in all catalysts is 5%, and the specific composition contents are shown in Table 1.

[0046] Table 1 Contents of each component in Cu-ATMP / AC, Cu-0.75ATMP / AC, Cu-0.35ATMP / AC

[0047]

[0048] Take 2mL of the above catalyst in a fixed-bed reactor for acetylene hydrochlorination. The reaction conditions a...

Embodiment 3

[0052] The specific operation steps are as follows:

[0053] (1) Dissolve 2 g of copper nitrate, 2 g of copper sulfate and 3 g of hydroxyethylidene diphosphonic acid (HEDP) in 15 ml of deionized water, and mix well to form a uniform mixed solution to obtain a mixed solution.

[0054] (2) Mix the mixed solution with 2.83g of wood charcoal activated carbon, stir evenly, and impregnate at 80°C for 24h.

[0055] (3) Dry at 60° C. for 24 hours to obtain the copper complex catalyst. The mass fraction of the organic phosphoric acid-containing ligand in the copper complex catalyst is 30.5%; the mass fraction of copper element in the copper complex catalyst is 15%.

[0056] A copper complex catalyst for acetylene hydrochlorination described in the embodiments of the present invention and its preparation method have the advantages of simple preparation method, convenient operation and low preparation cost; the prepared catalyst is a base metal catalyst, which is cheap and has Better a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com