ZrB2 ceramic with high thermal conductivity as well as preparation method and application of ZrB2 ceramic

A high thermal conductivity, zirconium boride technology, applied in the field of ultra-high temperature ceramic materials, can solve the problems of limited application, thermal resistance is not well solved, etc., to achieve the effect of improving density and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

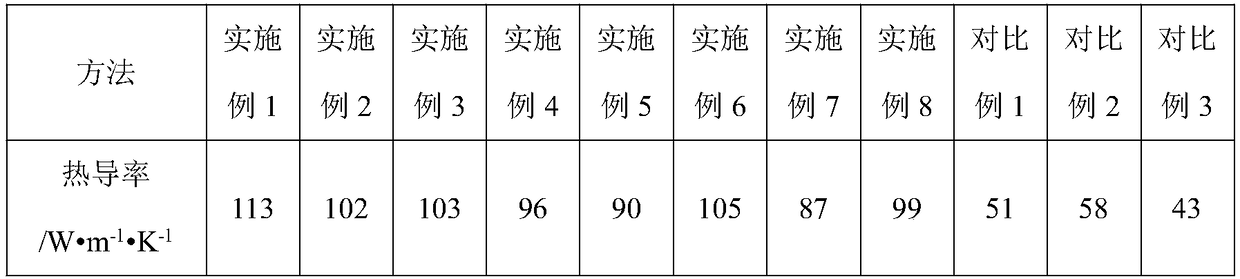

Examples

Embodiment 1

[0025] 1. Preparation:

[0026] (1) with ZrB 2 powder (purity 99%, particle size 0.8μm) as raw material, with B 2 o 3 (purity 99%, particle size 1μm) as a catalyst to promote grain growth, B powder (purity 99.9%, particle size 0.3μm) and C powder (purity 99.9%, particle size 0.33μm) as oxygen removal sintering aids . Press ZrB 2 :B 2 o 3 The mass ratio of B:C is 85:10:2:3 for batching, with ethanol as solvent, ZrB 2 The ball is used as the ball milling medium, and it is milled and mixed on a planetary ball mill at a speed of 200r / min for 4 hours. After mixing and drying, ZrB 2 -B 2 o 3 -B-C mixed powder;

[0027] (2) ZrB 2 -B 2 o 3 -Put the B-C mixed powder into a graphite mold, apply a pressure of 30MPa at a vacuum degree of <20Pa, raise the temperature to 1200°C at a rate of 10°C / min, and keep it warm for 2h;

[0028] (3) Then fill in 1 atm of argon, then raise the temperature to 1950°C at a rate of 10°C / min, and keep it warm for 2 hours. After the heat preserv...

Embodiment 2

[0031] 1. Preparation:

[0032] (1) with ZrB 2 powder (purity 99%, particle size 0.8μm) as raw material, with B 2 o 3 (purity 99%, particle size 1μm) as a catalyst to promote grain growth, B powder (purity 99.9%, particle size 0.3μm) and C powder (purity 99.9%, particle size 0.33μm) as oxygen removal sintering aids . Press ZrB 2 :B 2 o 3 : B: C mass ratio is 90:5:2:3 for batching, with ethanol as solvent, ZrB 2 The ball is used as the ball milling medium, and it is milled and mixed on a planetary ball mill at a speed of 200r / min for 4 hours. After mixing and drying, ZrB 2 -B 2 o 3 -B-C mixed powder;

[0033] (2) ZrB 2 -B 2 o 3 -Put the B-C mixed powder into a graphite mold, apply a pressure of 30MPa at a vacuum degree of <20Pa, raise the temperature to 1200°C at a rate of 10°C / min, and keep it warm for 2h;

[0034] (3) Then fill in 1 atm of argon, then raise the temperature to 1950°C at a rate of 10°C / min, and keep it warm for 2 hours. After the heat preservation...

Embodiment 3

[0037] 1. Preparation:

[0038] (1) with ZrB 2 powder (purity 99%, particle size 0.8μm) as raw material, with B 2 o 3 (purity 99%, particle size 1μm) as a catalyst to promote grain growth, B powder (purity 99.9%, particle size 0.3μm) and C powder (purity 99.9%, particle size 0.33μm) as oxygen removal sintering aids . Press ZrB 2 :B 2 o 3 The mass ratio of B:C is 85:10:2:3 for batching, with ethanol as solvent, ZrB 2 The ball is used as the ball milling medium, and it is milled and mixed on a planetary ball mill at a speed of 200r / min for 4 hours. After mixing and drying, ZrB2-B 2 o 3 -B-C mixed powder;

[0039] (2) ZrB 2 -B 2 o 3 -Put the B-C mixed powder into a graphite mold, apply a pressure of 30MPa at a vacuum degree of <20Pa, raise the temperature to 1100°C at a rate of 10°C / min, and keep it warm for 2h;

[0040] (3) Then fill in 1 atm of argon, then raise the temperature to 1850°C at a rate of 10°C / min, and keep it warm for 2 hours. After the heat preservati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com