Method for preparing cellulose nano microcrystal through solvothermal hydrolysis assisted mechanical grinding peeling

A technology of nano-microcrystals and auxiliary machinery, which is applied in the field of preparation of cellulose nano-crystals, can solve problems such as shortening the process flow, achieve the effects of shortening the process flow, reducing the amount of acid, and saving the dialysis link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

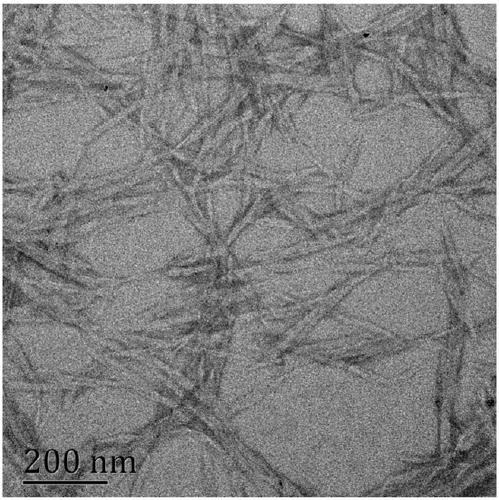

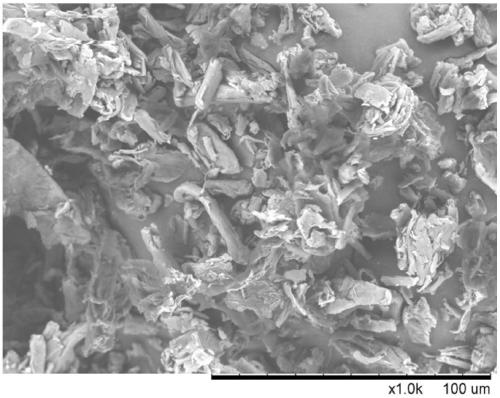

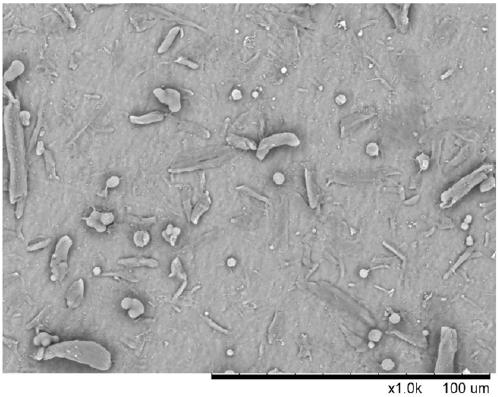

Embodiment 1

[0030] Take microcrystalline cellulose 5g, add microcrystalline cellulose in the mixed solvent (v / v=65 / 35) of 15mL ethanol and water and add the sulfuric acid of 100mM as catalyst, in polytetrafluoroethylene high-temperature high-pressure reaction kettle 200 Under the condition of ℃, react for 60min. Then add all the reacted solid-liquid mixture into a sand mill, then add 200g of zirconium beads and grind for 10 hours at 20°C to obtain a white jelly, add the white jelly to 100mL distilled water and stir evenly, and use deionized The water was centrifuged at 9000r / min for 5min and washed repeatedly by centrifugation for 5 times, the ethanol was removed, and the white precipitate was collected. After the white precipitate was shaken with water, the cellulose nanocrystal suspension obtained was ultrasonicated for 40min at a power of 100W. A cellulose nanocrystal suspension with uniform size is obtained. The yield is 75.6%, the diameter is 8-12 nanometers, and the length is about...

Embodiment 2

[0033] Take microcrystalline cellulose 5g, add microcrystalline cellulose in the mixed solvent (v / v=65 / 35) of 25mL ethanol and water and add the sulfuric acid of 80mM as catalyst, in polytetrafluoroethylene high-temperature high-pressure reactor 190 Under the condition of ℃, react for 80min. Then put all the reacted solid-liquid mixture into a sand mill, then add 150g of zirconium beads, and grind for 8 hours at 40°C to obtain a white jelly, add the white jelly to 100mL distilled water and stir evenly, use Ionized water was centrifuged at 9000r / min for 5min and washed with water for 4 times, ethanol was removed, and the white precipitate was collected. After the white precipitate was shaken with water, the cellulose nanocrystal suspension obtained was ultrasonicated for 30min at a power of 200W, that is, A suspension of cellulose nanocrystals with uniform size can be obtained. Yield 74.9%. The diameter is 9-15 nanometers, and the length is about 200-310 nanometers.

[0034]...

Embodiment 3

[0036] Take microcrystalline cellulose 5g, add microcrystalline cellulose in the mixed solvent (v / v=65 / 35) of 50mL ethanol and water and add the sulfuric acid of 60mM as catalyst, in polytetrafluoroethylene high-temperature high-pressure reactor 170 Under the condition of ℃, react for 120min. Then put all the reacted solid-liquid mixture into a sand mill, then add 150g of zirconium beads, and grind for 6 hours at 60°C to obtain a white jelly, add the white jelly to 100mL distilled water and stir evenly, use Ionized water was centrifuged at 9000r / min for 5min and washed 4-5 times by centrifugation repeatedly, the ethanol was removed, and the white precipitate was collected. After the white precipitate was shaken with water, the cellulose nanocrystal suspension obtained was ultrasonicated for 20min at a power of 300W. , the cellulose nanocrystal suspension with uniform size can be obtained. Yield 78.5%. The diameter is 9-13 nanometers, and the length is about 220-280 nanometer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com