Environment-friendly emulsion paint

A kind of latex paint, environment-friendly technology, applied in the direction of latex paint, paint containing biocide, coating, etc., can solve the problem of poor stain resistance of the coating film, to improve the scrub resistance, improve the contrast ratio and stain resistance, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

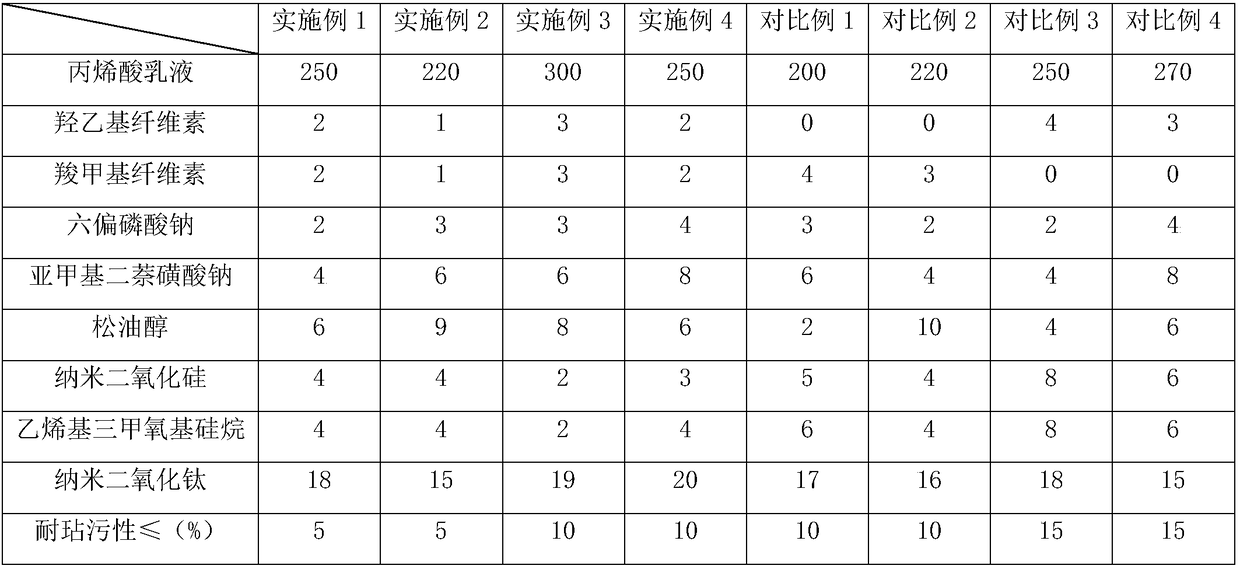

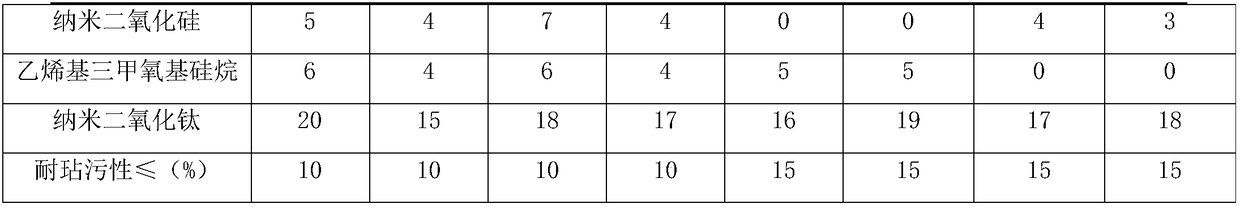

Embodiment 1

[0033] Embodiment 1, a kind of environment-friendly latex paint, by weight, the composition of raw material is as shown in table 1. Wherein, the latex paint is prepared through the following steps:

[0034] Step 1, add water to the mixer, add hydroxyethyl cellulose, carboxymethyl cellulose, stir evenly, add ammonia water to dissolve the hydroxyethyl cellulose and continue stirring until uniform to obtain a compound glue;

[0035] Step 2, continue to drop into the sodium hexametaphosphate solution dissolved in hot water in the mixer, then drop into sodium methylene dinaphthalene sulfonate and stir evenly, continue to drop into terpineol and stir evenly to obtain a mixed glue;

[0036] Step 3: Stir vinyltrimethoxysilane and nano-silica evenly, put them into a blender and mix with the mixed glue to a uniform state, then add nano-titanium dioxide and continue to stir evenly to obtain a mixed slurry;

[0037] Step 4, putting the mixed slurry into a sander for grinding to obtain a ...

Embodiment 2

[0039] Embodiment 2, an environment-friendly latex paint, differs from Embodiment 1 in that, by weight, the components of the raw materials are as shown in Table 1.

Embodiment 3

[0040] Embodiment 3, an environment-friendly latex paint, the components of the raw materials are shown in Table 1 in parts by weight. Wherein, the latex paint is prepared through the following steps:

[0041] Step 1, add water to the mixer, add hydroxyethyl cellulose, carboxymethyl cellulose, stir evenly, add ammonia water to dissolve the hydroxyethyl cellulose and continue stirring until uniform to obtain a compound glue;

[0042] Step 2, continue to drop into the sodium hexametaphosphate solution dissolved in hot water in the mixer, then drop into sodium methylene dinaphthalene sulfonate and stir evenly, continue to drop into terpineol and stir evenly to obtain a mixed glue;

[0043] Step 3: Stir vinyltrimethoxysilane and nano-silica evenly, put them into a mixer and mix with the mixed glue to a uniform state to obtain a mixed slurry;

[0044] Step 4, putting the mixed slurry into a sander for grinding to obtain a finely ground slurry;

[0045] Step 5, uniformly mixing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com