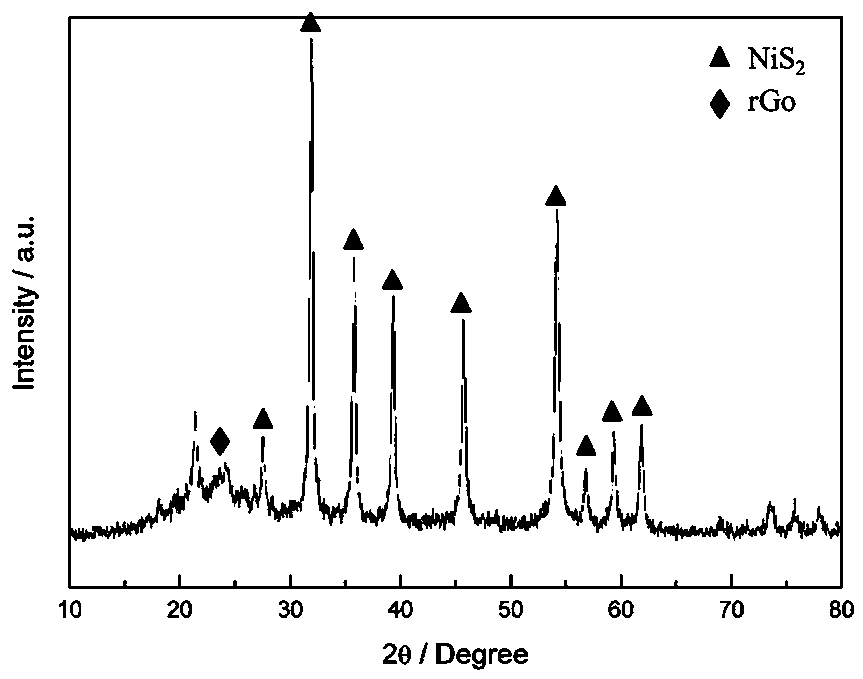

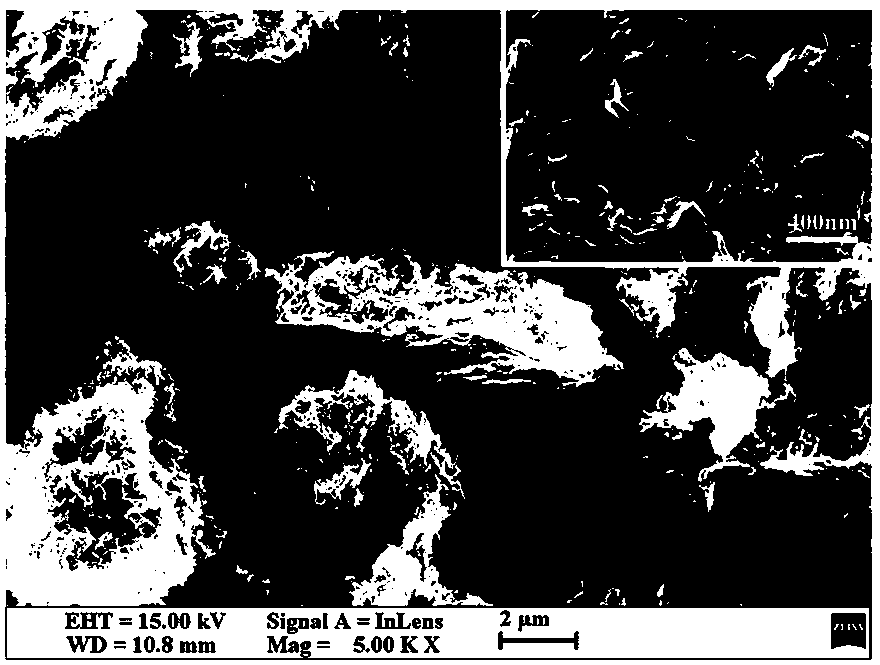

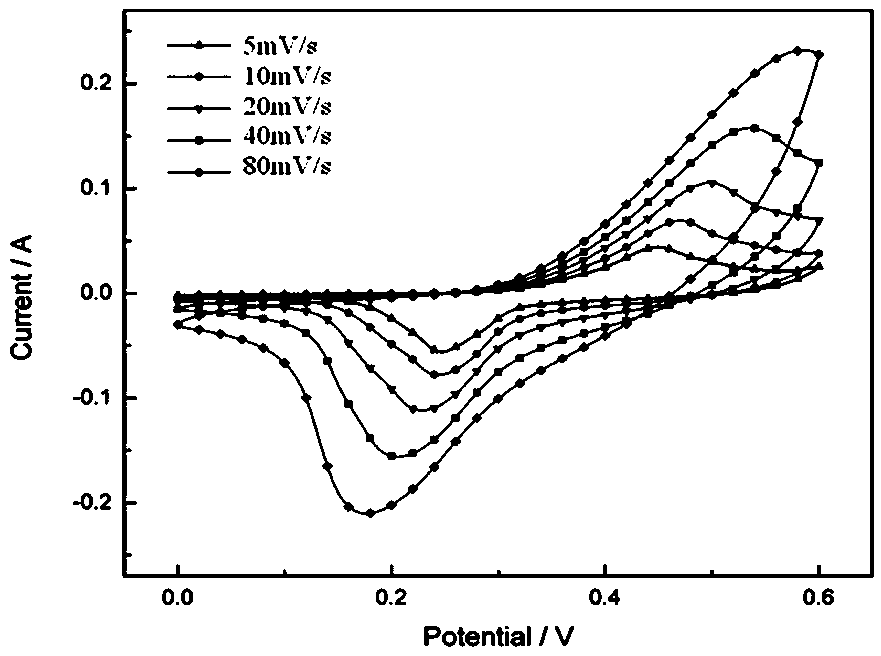

Preparation method and application of spongy graphene/nickel-cobalt sulfide composite material

A technology of nickel-cobalt sulfide and composite materials, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of lower specific surface area, easy agglomeration of graphene, and unsatisfactory performance, and achieve high specific surface area, simple impurity removal process, and low pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of spongy graphene / nickel-cobalt sulfide composite material, concrete process is as follows:

[0033] (1) Weigh 0.1g of graphene oxide and 1g of sodium dodecylbenzenesulfonate and dissolve them in 20mL of deionized water respectively, mix the two and ultrasonicate, the ultrasonic power is 200W, the ultrasonic temperature is 25°C, and the ultrasonic time is 2h;

[0034] (2) Weigh 0.3g of sulfur and ultrasonically disperse it in 20mL of n-octane, add the obtained n-octane mixture dropwise to the solution obtained in step (1), and stir magnetically for 60 minutes;

[0035] (3) Weigh 0.2g of nickel nitrate and 0.1g of cobalt nitrate and dissolve them in deionized water, and add them dropwise to the mixed solution in step (2), and stir magnetically for 30 minutes;

[0036] (4) Transfer the mixture obtained in step (3) to a 100mL Teflon-lined stainless steel autoclave, then place it in an oil bath, and place it in an oil bath at 180°C for 24 hour...

Embodiment 2

[0040] A kind of preparation method of spongy graphene / nickel-cobalt sulfide composite material, concrete process is as follows:

[0041] (1) Weigh 0.1g of graphene oxide and 1g of sodium dodecylbenzenesulfonate and dissolve them in 20mL of deionized water respectively, mix the two and ultrasonicate, the ultrasonic power is 200W, the ultrasonic temperature is 25°C, and the ultrasonic time is 2h;

[0042] (2) Weigh 0.3g of sulfur and ultrasonically disperse it in 20mL of n-octane, add the obtained n-octane mixture dropwise to the solution obtained in step (1), and stir magnetically for 60 minutes;

[0043] (3) Weigh 0.15g of nickel nitrate and 0.15g of cobalt nitrate and dissolve them in deionized water, and add them dropwise to the mixed solution in step (1), and stir magnetically for 30 minutes;

[0044] (4) Transfer the mixture obtained in step (3) to a 100mL Teflon-lined stainless steel autoclave, then place it in an oil bath, and place it in an oil bath at 180°C for 24 ho...

Embodiment 3

[0048] A kind of preparation method of spongy graphene / nickel-cobalt sulfide composite material, concrete process is as follows:

[0049] (1) Weigh 0.1g of graphene oxide and 1g of sodium dodecylbenzenesulfonate and dissolve them in 20mL of deionized water respectively, mix the two and ultrasonicate, the ultrasonic power is 200W, the ultrasonic temperature is 25°C, and the ultrasonic time is 2h;

[0050] (2) Weigh 0.3g of sulfur and ultrasonically disperse it in 20mL of n-octane, add the obtained n-octane mixture dropwise to the solution obtained in step (1), and stir magnetically for 60 minutes;

[0051] (3) Weigh 0.1g of nickel nitrate and 0.2g of cobalt nitrate and dissolve them in deionized water, and add them dropwise to the mixed solution in step (2), and stir magnetically for 30 minutes;

[0052] (4) Transfer the mixture obtained in step (3) to a 100mL Teflon-lined stainless steel autoclave, then place it in an oil bath, and place it in an oil bath at 180°C for 24 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com