Preparation method of vitaminB6 sustained release preparation

A technology of sustained-release preparations and vitamins, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc. Good release function, high production efficiency, and moderate dosage of capsule material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

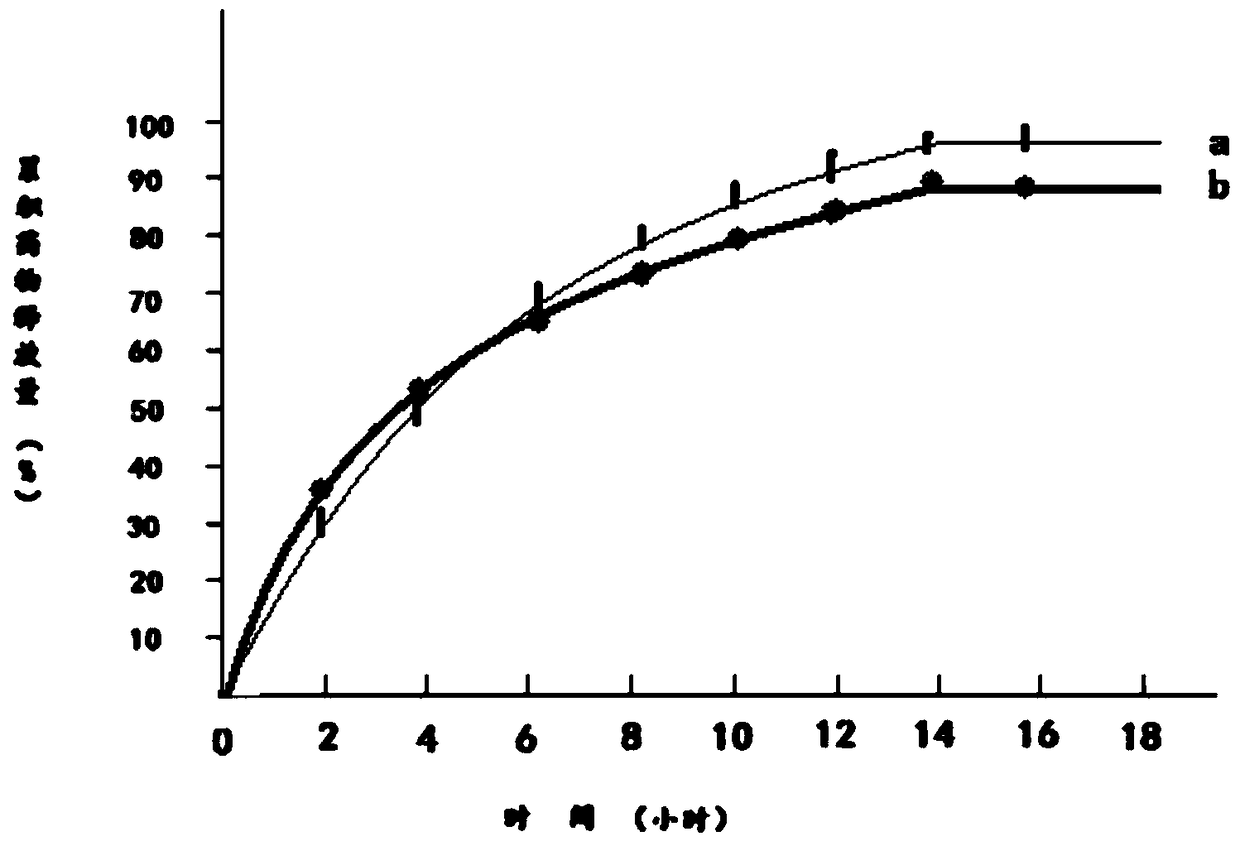

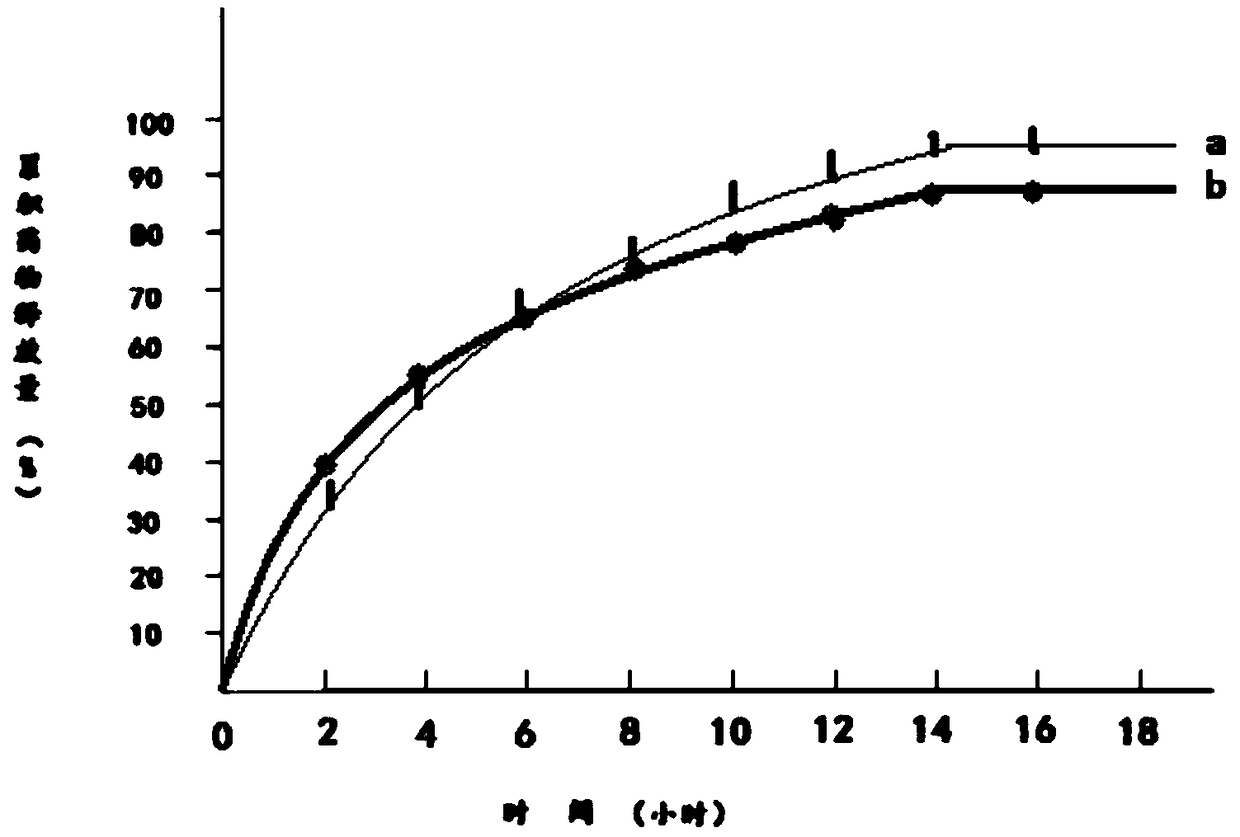

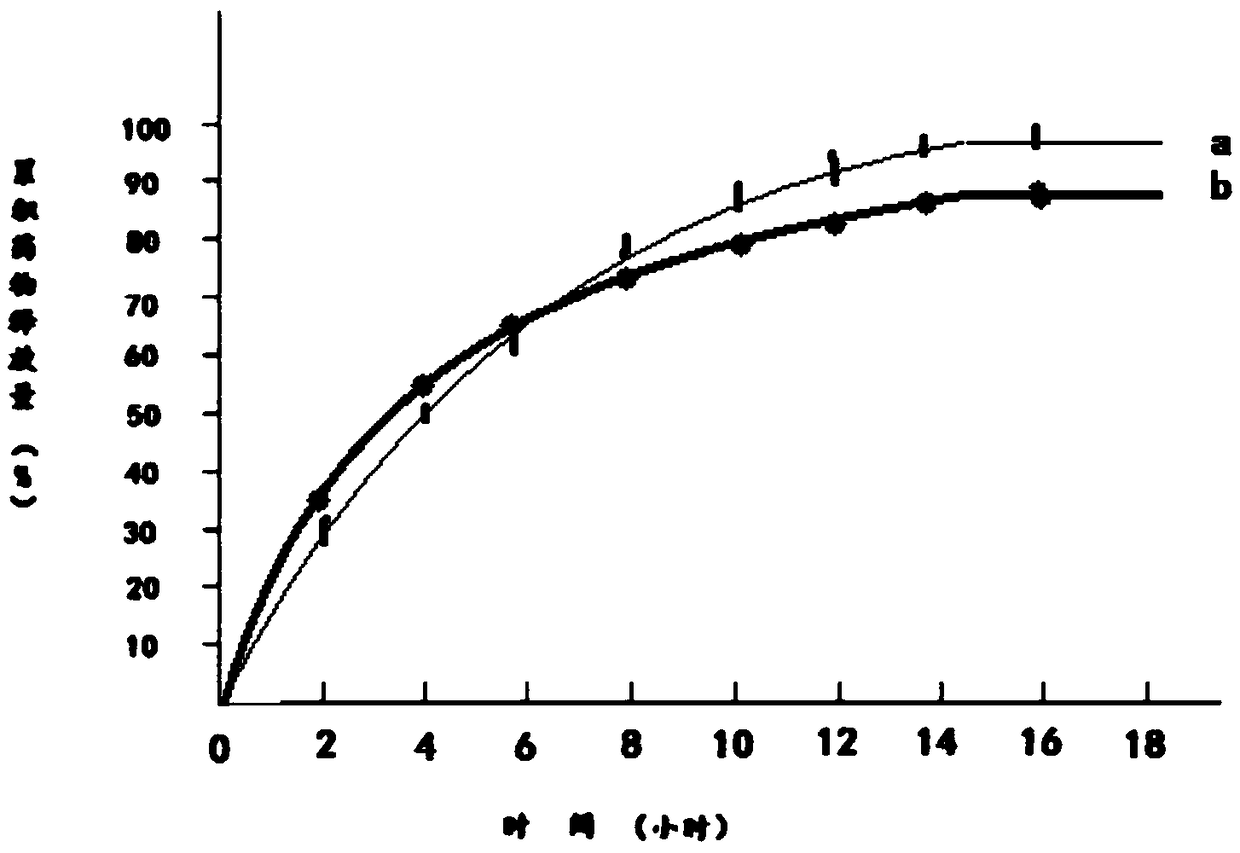

Image

Examples

Embodiment 1

[0023] 1) Dissolve 100g of vitamin B6 in 110g of 95% ethanol to obtain a vitamin B6 ethanol solution, which is denoted as solution A;

[0024] 2) Add 110g of hydroxypropyl β-cyclodextrin and 20g of mannitol to solution A to obtain solution B;

[0025] 3) Dissolve 130g of polylactic acid and 20g of polyethylene glycol 200 in 130g of acetone to obtain a solution of polylactic acid and polyethylene glycol 200, which is referred to as solution C;

[0026] 4) Mix solution B and solution C to obtain solution D;

[0027] 5) Transfer solution D to a magnetic stirrer, control the temperature of solution D at 15°C to 18°C, continuously stir solution D for 12 hours, then reduce the temperature of solution D to 0°C to 1°C within 2 hours and let it stand for 12 hours. Hours, keep the temperature of solution D at 0°C to 1°C during the standing period;

[0028] 6) Heat the solution D obtained in step 5, and stir continuously for 12 hours when the temperature of the solution D rises to 15°C...

Embodiment 2

[0032] 1) Dissolve 100g of vitamin B6 in 120g of 95% ethanol to obtain a vitamin B6 ethanol solution, which is denoted as solution A;

[0033] 2) Add 120g of hydroxypropyl β-cyclodextrin and 25g of mannitol to solution A to obtain solution B;

[0034] 3) Dissolve 140g of polylactic acid and 30g of polyethylene glycol 200 in 140g of acetone to obtain a solution of polylactic acid and polyethylene glycol 200, which is referred to as solution C;

[0035] 4) Mix solution B and solution C to obtain solution D;

[0036] 5) Transfer solution D to a magnetic stirrer, control the temperature of solution D at 15°C to 18°C, continuously stir solution D for 12 hours, then reduce the temperature of solution D to 0°C to 1°C within 2 hours and let it stand for 12 hours. Hours, keep the temperature of solution D at 0°C to 1°C during the standing period;

[0037] 6) Heat the solution D obtained in step 5, and stir continuously for 12 hours when the temperature of the solution D rises to 15°C...

Embodiment 3

[0041] 1) Dissolve 100g of vitamin B6 in 130g of 95% ethanol to obtain a vitamin B6 ethanol solution, which is denoted as solution A;

[0042] 2) Add 130g of hydroxypropyl β-cyclodextrin and 30g of mannitol to solution A to obtain solution B;

[0043] 3) Dissolve 150g of polylactic acid and 40g of polyethylene glycol 200 in 150g of acetone to obtain a solution of polylactic acid and polyethylene glycol 200, which is referred to as solution C;

[0044] 4) Mix solution B and solution C to obtain solution D;

[0045] 5) Transfer solution D to a magnetic stirrer, control the temperature of solution D at 15°C to 18°C, continuously stir solution D for 12 hours, then reduce the temperature of solution D to 0°C to 1°C within 2 hours and let it stand for 12 hours. Hours, keep the temperature of solution D at 0°C to 1°C during the standing period;

[0046]6) Heat the solution D obtained in step 5, and stir continuously for 12 hours when the temperature of the solution D rises to 15°C-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com