Reverse osmosis membrane scale inhibitor and preparation method thereof and application thereof in raw water treatment of petroleum coke calcination

A technology of reverse osmosis membrane and scale inhibitor, which is applied in the field of scale inhibition and can solve problems such as poor scale inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

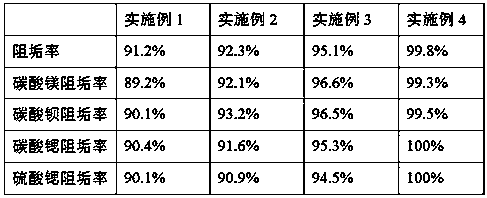

Examples

Embodiment 1

[0026] Example 1 A reverse osmosis membrane scale inhibitor

[0027] The scale inhibitor includes the following raw materials in parts by weight: 5 parts of benzalkonium chloride, 15 parts of 2-hydroxyphosphinoacetic acid, 4 parts of sorbic acid, 3 parts of L-hydroxyproline, cetyl sulfonate 2 parts of sodium bicarbonate, 18 parts of 2-hydroxy-4-(methylthio)butyric acid, 7 parts of dodecyldimethylbenzyl ammonium chloride, and 60 parts of deionized water.

[0028] Described benzalkonium chloride: active substance content 95%.

[0029] Described 2-hydroxyphosphinoacetic acid: active substance content is 55%;

[0030] Described sorbic acid: fineness is 200 orders, and mass percentage composition is 96.5%;

[0031] Described L-hydroxyproline: active substance content is 99%.

Embodiment 2

[0032] Example 2 A reverse osmosis membrane scale inhibitor

[0033] The scale inhibitor includes the following raw materials in parts by weight: 6 parts of benzalkonium chloride, 12 parts of 2-hydroxyphosphinoacetic acid, 4.3 parts of sorbic acid, 3 parts of L-hydroxyproline, cetyl sulfonate 1.5 parts of sodium bicarbonate, 15 parts of 2-hydroxy-4-(methylthio)butanoic acid, 7.5 parts of dodecyldimethylbenzyl ammonium chloride, and 60 parts of deionized water.

[0034] Described benzalkonium chloride: active substance content 95%.

[0035] Described 2-hydroxyphosphinoacetic acid: active substance content is 55%;

[0036] Described sorbic acid: fineness is 200 orders, and mass percentage composition is 96.5%;

[0037] Described L-hydroxyproline: active substance content is 99%.

Embodiment 3

[0038] Example 3 A reverse osmosis membrane scale inhibitor

[0039] The scale inhibitor includes the following raw materials in parts by weight: 9 parts of benzalkonium chloride, 14 parts of 2-hydroxyphosphinoacetic acid, 4 parts of sorbic acid, 4 parts of L-hydroxyproline, cetyl sulfonate 2 parts of sodium nitrate, 18 parts of 2-hydroxy-4-(methylthio)butyric acid, 23 parts of ellagic acid, 13 parts of β-sitosterol, 60 parts of deionized water.

[0040] Described benzalkonium chloride: active substance content 95%.

[0041] Described 2-hydroxyphosphinoacetic acid: active substance content is 55%;

[0042] Described sorbic acid: fineness is 200 orders, and mass percentage composition is 96.5%;

[0043] Described L-hydroxyproline: active substance content is 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com