Preparation methods for metal/black phosphorus nanosheet composite material, black phosphorus and black phosphorene

A composite material and nanosheet technology, which is applied in the field of metal/black phosphorus nanosheet composite material, black phosphorus and black phosphorus preparation, can solve the problems of high cost, complicated process operation, large pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

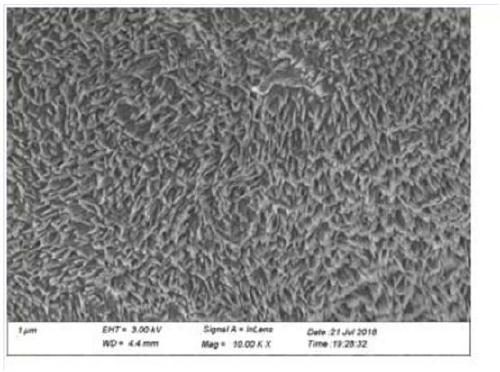

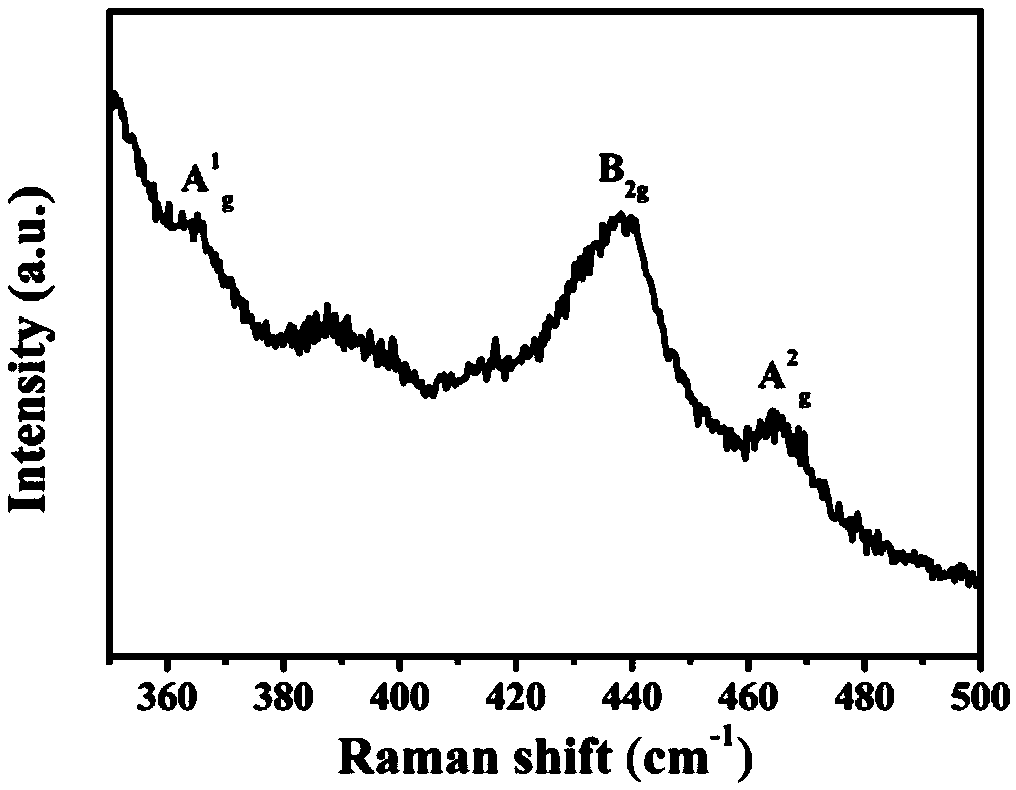

Embodiment 1

[0033] The preparation method of metal / black phosphorus nanosheet composite material comprises the following steps:

[0034] Put 1g of iron powder and 10g of red phosphorus powder in a mortar and grind for 20min to obtain ground powder;

[0035] Put the grinding powder into the quartz ambe bottle, then seal the quartz ambe bottle containing the grinding powder, and then put it into the reaction chamber;

[0036] Introduce argon gas into the reaction chamber, and heat the reaction chamber to 550°C and keep it for 10h, then cool the reaction chamber to 400°C and keep it for 9h, and finally cool to room temperature to obtain the iron / black phosphorus nanosheet composite material.

[0037] The preparation method of black phosphorus comprises the following steps:

[0038] The iron / black phosphorus nanosheet composite material is treated with acetone at a temperature of 50 degrees, and then the mixture is sequentially filtered and cooled to obtain black phosphorus.

[0039] The pr...

Embodiment 2

[0041] The preparation method of metal / black phosphorus nanosheet composite material comprises the following steps:

[0042] Put 20g of copper powder and 800g of red phosphorus powder in a mortar and grind for 30min to obtain ground powder;

[0043] Put the grinding powder into the ground quartz glass test tube, then seal the ground quartz glass test tube with the grinding powder, and then put it into the reaction chamber;

[0044] Nitrogen was introduced into the reaction chamber, and the reaction chamber was heated to 530°C and kept for 15h, then cooled to 300°C and kept for 8h, and finally cooled to room temperature to obtain a copper / black phosphorus nanosheet composite material.

[0045] The preparation method of black phosphorus comprises the following steps:

[0046] The copper / black phosphorus nanosheet composite material is treated with toluene at a temperature of 80 degrees, and then the mixture is filtered and cooled in sequence to obtain black phosphorus.

[0047...

Embodiment 3

[0049] The preparation method of metal / black phosphorus nanosheet composite material comprises the following steps:

[0050] Put 100g of titanium powder and 20g of red phosphorus powder in a mortar and grind for 30min to obtain ground powder;

[0051] Put the grinding powder into the quartz ambe bottle, then put the quartz ambe bottle with the grinding powder into the reaction chamber without sealing the mouth;

[0052] Introduce argon gas into the reaction chamber, and heat the reaction chamber to 900°C and keep it for 18h, then cool the reaction chamber to 410°C and keep it for 8h, and finally cool to room temperature to obtain the titanium / black phosphorus nanosheet composite material.

[0053] The preparation method of black phosphorus, comprises the following steps:

[0054] The titanium / black phosphorus nanosheet composite material is treated with ethanol at a temperature of 70 degrees, and then the mixture is filtered and cooled in sequence to obtain black phosphorus.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com