Production method of nano rare earth oxide powder

A technology of oxide powder and nano-rare earth, which is applied in the direction of rare earth metal oxide/hydroxide, lanthanide oxide/hydroxide, nanotechnology, etc., and can solve the problem of high cost and precipitation of nano-rare earth oxide powder technology. Eliminate the problems of difficult filtration of particles, washing, and unsuitability of precipitation method for industrialization, etc., to achieve the effect of fine particles, uniform shape, and narrow particle size distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

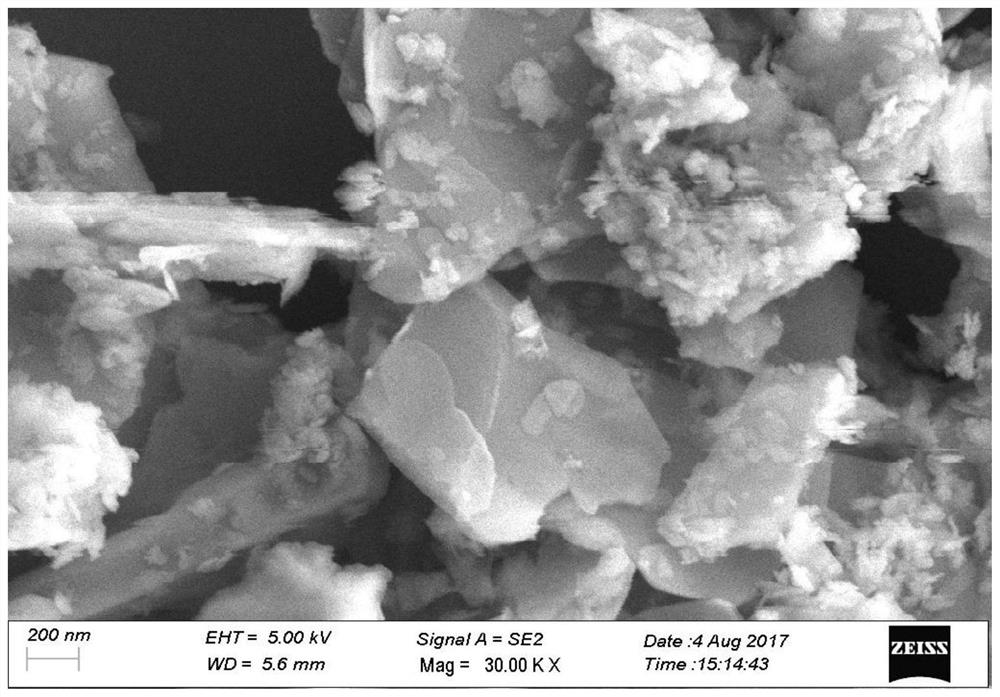

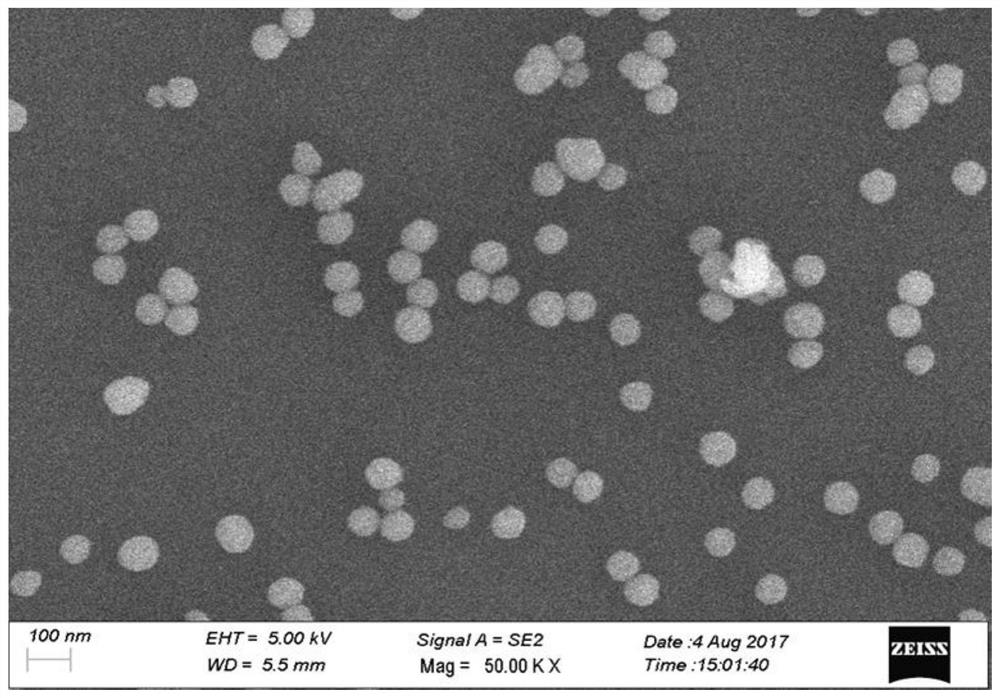

[0053] Dilute the 2.0mol / L cerium chloride solution with deionized water to prepare a rare earth feed solution with a concentration of 1.2mol / L, heat the cerium chloride solution to a constant temperature of 60°C, and at the same time, stir the stirrer at a speed of 400rpm , the pre-prepared 3mol / L ammonium bicarbonate solution (according to the mass ratio of rare earth salt solution and ammonium bicarbonate 1:1.5) is continuously and rapidly added to the cerium chloride solution under stirring, and the precipitant solution is continued after adding the precipitant solution. Stir for 30 minutes until all the generated carbon dioxide gas overflows. At this time, the amorphous precipitate after the normal pressure precipitation reaction is obtained; stop stirring, adjust the temperature and pressure of the reaction kettle, so that the temperature of the precipitation slurry reaches 110 °C and the pressure is 0.2 MPa, and the temperature is maintained for 30 minutes ;Wash the prec...

Embodiment 2

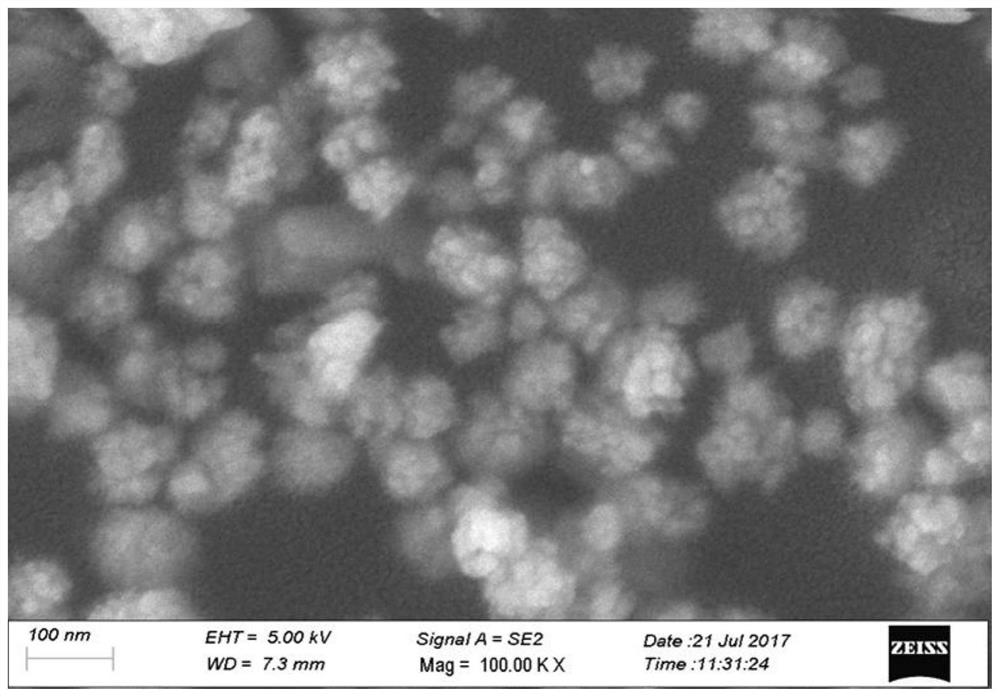

[0055] Dilute the 1.8 mol / L neodymium nitrate solution with deionized water to prepare a rare earth feed solution with a concentration of 1.0 mol / L, heat the neodymium nitrate solution to a constant temperature of 50°C, and simultaneously stir the stirrer at a speed of 350 rpm. Pre-prepared 2mol / L ammonium bicarbonate solution (according to the mass ratio of rare earth salt solution and ammonium bicarbonate 1:1.5) was continuously and rapidly added to the neodymium nitrate solution under stirring, and continued to stir for 20 minutes to All the generated carbon dioxide gas overflows, and the amorphous precipitate after the normal pressure precipitation reaction is obtained at this time; stop stirring, adjust the temperature and pressure of the reactor, make the temperature of the precipitation slurry reach 120 ° C, the pressure is 0.3 MPa, and keep the heat and pressure for 50 minutes; Wash the slurry with deionized water at room temperature until the filtrate does not become t...

Embodiment 3

[0057] Dilute the 1.7 mol / L lanthanum cerium chloride solution with deionized water to prepare a rare earth feed solution with a concentration of 1.1 mol / L, heat the lanthanum cerium chloride solution to a constant temperature of 60°C, and at the same time, the stirrer rotates rapidly at 400rpm Stirring, the pre-prepared 1.5mol / L ammonium bicarbonate solution (according to the mass ratio of rare earth salt solution and ammonium bicarbonate 1:1.5) is continuously and rapidly added to the lanthanum cerium chloride solution under stirring, and the precipitant solution is added After the completion, continue to stir for 30 minutes until all the generated carbon dioxide gas overflows. At this time, the amorphous precipitate after the normal pressure precipitation reaction is obtained; stop stirring, adjust the temperature and pressure of the reactor, so that the temperature of the precipitated slurry reaches 95 °C and the pressure is close to 0.2 MPa. Hold the pressure for 40 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com