Device and method for treating high concentration refractory organic wastewater

A technology for organic wastewater treatment and organic wastewater, which is applied in the field of water treatment and can solve the problems of long multi-stage filtration process and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

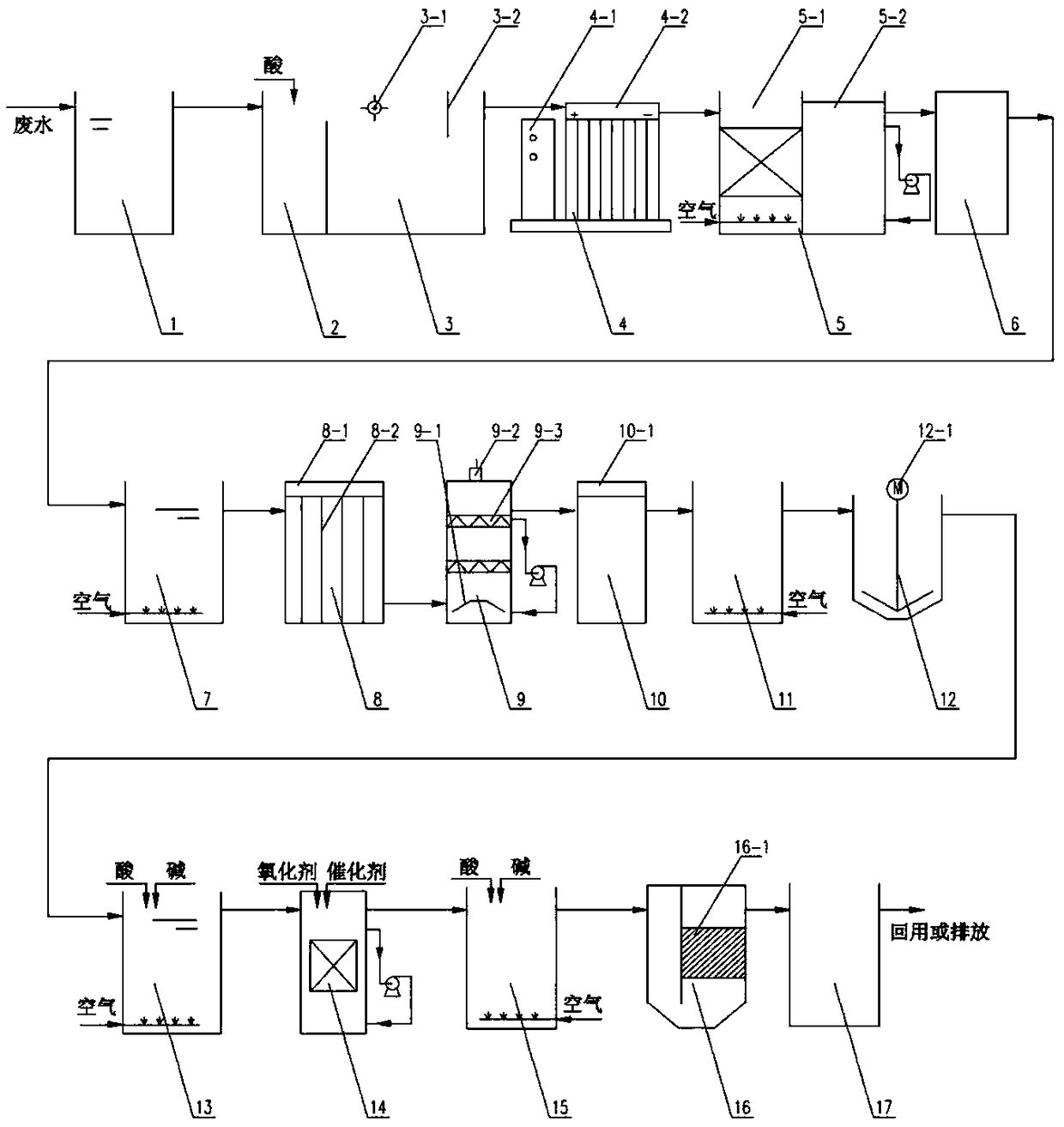

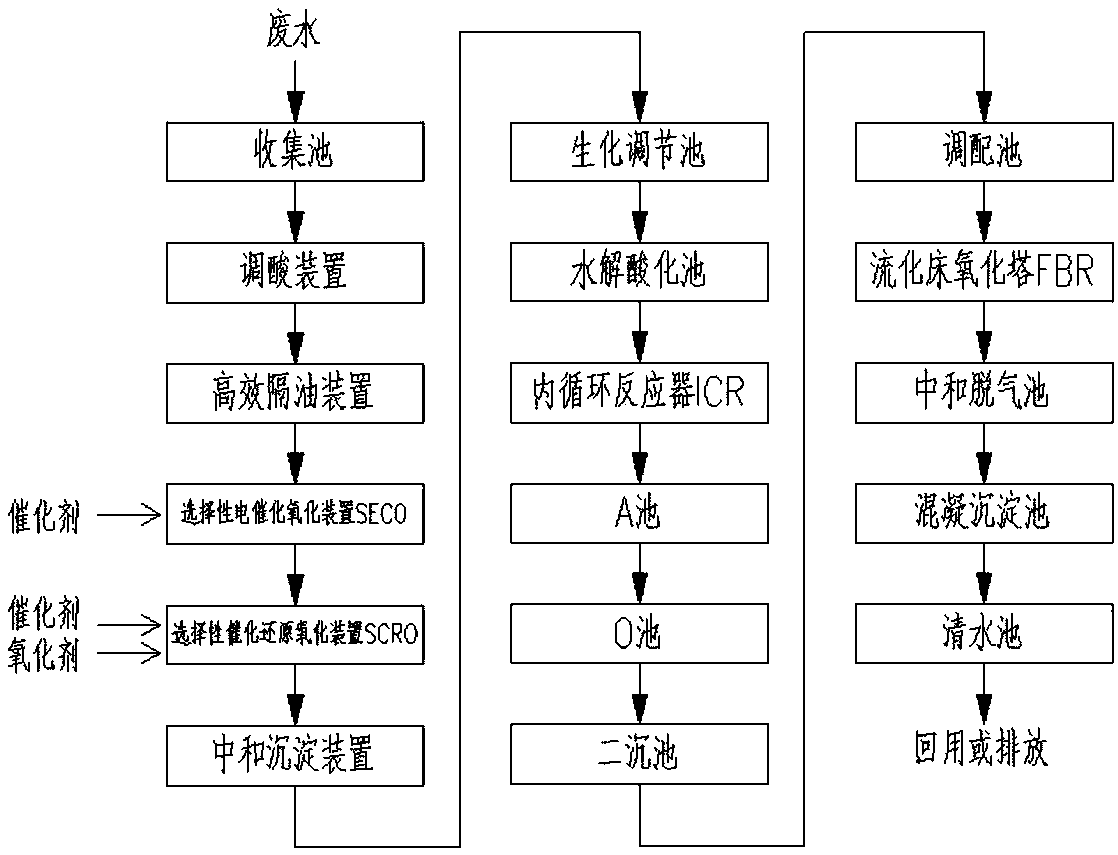

[0054] Embodiment 1: as figure 1 As shown, the high-concentration refractory organic wastewater treatment device includes a pretreatment system, a biochemical treatment system, and an advanced treatment system connected in sequence through system pipes; the pretreatment system includes a collection pool 1, an acid adjustment device 2, and an efficient Oil separation device 3, selective electrocatalytic oxidation device (SECO) 4, selective catalytic reduction oxidation reactor (SCRO) 5 and neutralization sedimentation tank 6, said selective catalytic reduction oxidation reactor (SCRO) 5 includes catalytic selection Selective catalytic reduction device (SCR) 5-1 and selective catalytic oxidation device (SCO) 5-2, the selective catalytic reduction device (SCR) 5-1 and the selective catalytic oxidation device (SCO) 5-2 are mutually independent and connected in sequence; the biochemical treatment system includes a biochemical regulation tank 7, a hydrolysis acidification tank 8, an...

Embodiment 2

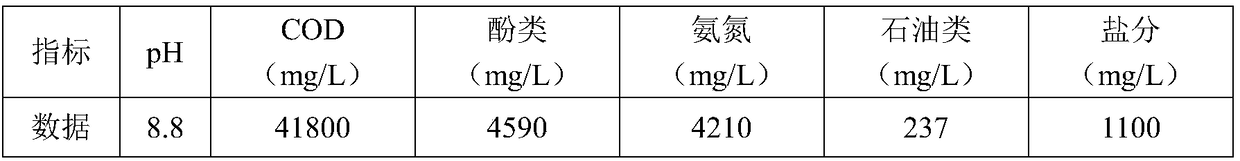

[0074] Embodiment 2: adopt the device and method in implementing 1, take the high-concentration refractory organic waste water that is blue charcoal waste water that gets with a coking plant in Shaanxi as an example, the waste water quality index is as follows table 1:

[0075] Table 1 Blue carbon wastewater water quality index

[0076]

[0077] The waste water 1000m 3 / d, one-pass pretreatment system, biochemical treatment system and advanced treatment system;

[0078] (1) Pretreatment process: the pretreatment system includes a sequentially connected collection pool 1, acid adjustment device 2, high-efficiency oil separation device 3, selective electrocatalytic oxidation device (SECO) 4, selective catalytic reduction oxidation device (SCRO) 5 , neutralization sedimentation tank 6;

[0079] S11 Acid adjustment: After the organic wastewater is discharged into the collection pool 1, it is pumped to the acid adjustment device 2 to add sulfuric acid and / or hydrochloric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com