Method for preparing microcrystalline cellulose by electron beam irradiation

A technology of microcrystalline cellulose and electron beam irradiation, applied in the field of microcrystalline cellulose preparation, can solve the problems of large consumption of inorganic acid, a large amount of waste acid solution, environmental pollution, etc., and achieves high production efficiency, simple and convenient process, and improved income. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

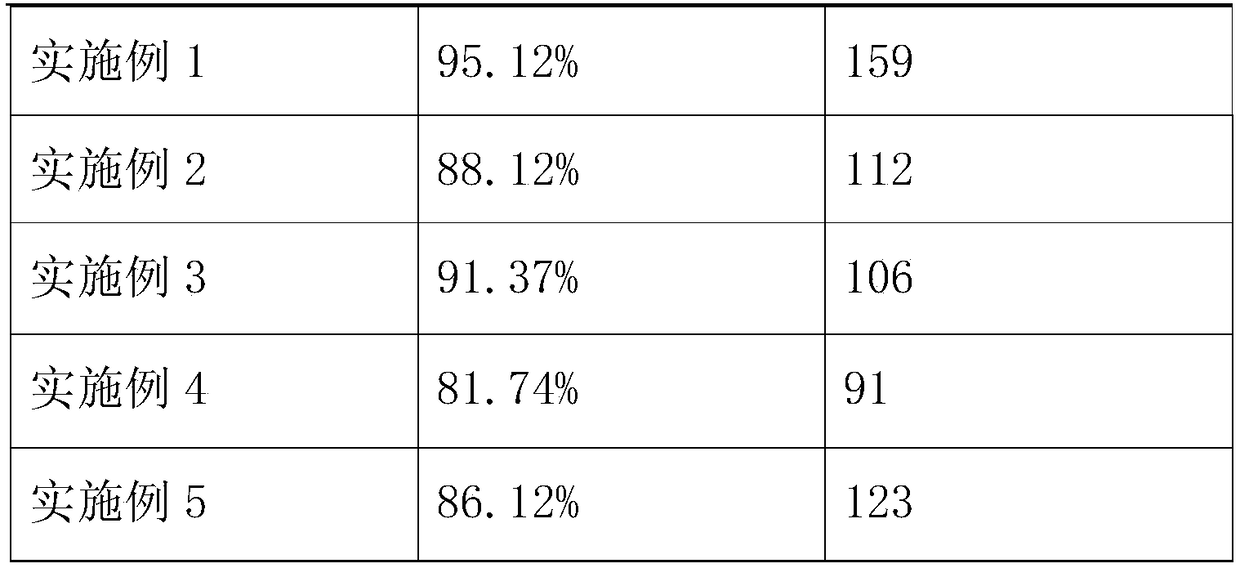

Examples

Embodiment 1

[0021] A method for preparing microcrystalline cellulose by electron beam radiation, comprising the following steps:

[0022] S1: Take an appropriate amount of natural cellulose pulp and place it under high-energy ionizing radiation for degradation treatment;

[0023] S2: chop the degraded natural cellulose pulp with a cutting machine and put it into a kneader;

[0024] S3: adding an appropriate amount of dilute acid aqueous solution to a kneader with natural cellulose pulp, and kneading the mixed material for a certain period of time at a certain temperature to obtain a paste;

[0025] S4: washing the paste obtained in S3 multiple times, filtering and separating the washed mixture to obtain solid matter, repeatedly washing and filtering the solid matter until the solid matter does not contain acid solution;

[0026] S5: drying the cleaned solid in S4 and then grinding and pulverizing to obtain microcrystalline cellulose.

[0027] Specifically, natural cellulose pulp include...

Embodiment 2

[0032] A method for preparing microcrystalline cellulose by electron beam radiation, comprising the following steps:

[0033] S1: Take an appropriate amount of natural cellulose pulp and place it under high-energy ionizing radiation for degradation treatment;

[0034] S2: chop the degraded natural cellulose pulp with a cutting machine and put it into a kneader;

[0035] S3: adding an appropriate amount of dilute acid aqueous solution to a kneader with natural cellulose pulp, and kneading the mixed material for a certain period of time at a certain temperature to obtain a paste;

[0036] S4: washing the paste obtained in S3 multiple times, filtering and separating the washed mixture to obtain solid matter, repeatedly washing and filtering the solid matter until the solid matter does not contain acid solution;

[0037] S5: drying the cleaned solid in S4 and then grinding and pulverizing to obtain microcrystalline cellulose.

[0038] Specifically, natural cellulose pulp include...

Embodiment 3

[0043] A method for preparing microcrystalline cellulose by electron beam radiation, comprising the following steps:

[0044] S1: Take an appropriate amount of natural cellulose pulp and place it under high-energy ionizing radiation for degradation treatment;

[0045] S2: chop the degraded natural cellulose pulp with a cutting machine and put it into a kneader;

[0046] S3: adding an appropriate amount of dilute acid aqueous solution to a kneader with natural cellulose pulp, and kneading the mixed material for a certain period of time at a certain temperature to obtain a paste;

[0047] S4: washing the paste obtained in S3 multiple times, filtering and separating the washed mixture to obtain solid matter, repeatedly washing and filtering the solid matter until the solid matter does not contain acid solution;

[0048] S5: drying the cleaned solid in S4 and then grinding and pulverizing to obtain microcrystalline cellulose.

[0049] Specifically, natural cellulose pulp include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com