Method for obtaining ferulic acid by using wastes

A technology for ferulic acid and waste, applied in the field of obtaining ferulic acid, can solve the problems of immature process, difficult separation, long production cycle, etc., and achieve the effects of less capital investment, stable reaction process and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

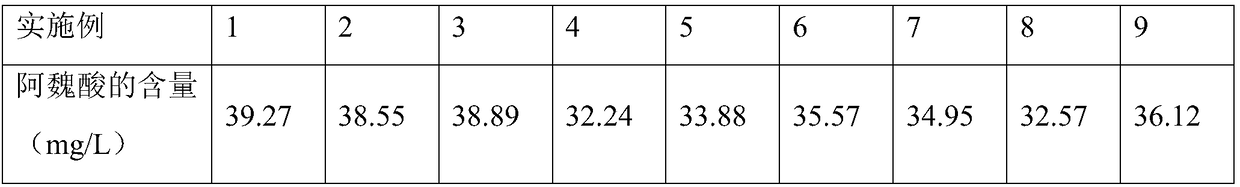

Examples

Embodiment 1

[0022] In this example, the mixing ratio of distiller's grains and bran is 1:1, the cultivation temperature is 30°C, and the extraction temperature of ferulic acid in the distiller's grains solid-state fermentation product is extracted by hot water extraction method is 60°C;

[0023] (1) Preparation of Cladosporium spore suspension

[0024] Streak-inoculate the Cladosporium spores stored in glycerol tubes on PDA solid medium, culture at 30°C for 3 days, then add 5mL sterile saline to each plate to wash the spores generated by the mycelium, and make a spore suspension .

[0025] (2) Seed medium and cultivation

[0026] The seed medium of Cladosporium cladoides is a liquid PDA medium, and the liquid volume in 250mL is 100mL and 10 glass beads are added. After sterilization, 3 mL of the spore suspension in step (1) was inserted, and the spore density was 1×10 6 / mL, and cultured at 30° C. and 150 rpm for 5 days.

[0027] (3) Solid-state fermentation of distiller's grains

[0...

Embodiment 2

[0032] In this example, the mixing ratio of distiller's grains and bran is 1:1, the cultivation temperature is 30°C, and the extraction temperature of ferulic acid in the distiller's grains solid-state fermentation product is extracted by hot water extraction method is 60°C;

[0033] (1) Preparation of Cladosporium spore suspension

[0034] Streak-inoculate the Cladosporium spores stored in glycerol tubes on PDA solid medium, culture at 30°C for 3 days, then add 5mL sterile saline to each plate to wash the spores generated by the mycelium, and make a spore suspension .

[0035] (2) Seed medium and cultivation

[0036] The seed medium of Cladosporium cladoides is a liquid PDA medium, and the liquid volume in 250mL is 100mL and 10 glass beads are added. After sterilization, 3 mL of the spore suspension in step (1) was inserted, and the spore density was 1×10 6 / mL, and cultured at 30° C. and 150 rpm for 4 days.

[0037] (3) Solid-state fermentation of distiller's grains

[0...

Embodiment 3

[0042] In this example, the mixing ratio of distiller's grains and bran is 1:1, the cultivation temperature is 30°C, and the extraction temperature of ferulic acid in the distiller's grains solid-state fermentation product is extracted by hot water extraction method is 60°C;

[0043] (1) Preparation of Cladosporium spore suspension

[0044] Streak-inoculate the Cladosporium spores stored in glycerol tubes on PDA solid medium, culture at 30°C for 3 days, then add 5mL sterile saline to each plate to wash the spores generated by the mycelium, and make a spore suspension .

[0045] (2) Seed medium and cultivation

[0046] The seed medium of Cladosporium cladoides is a liquid PDA medium, and the liquid volume in 250mL is 100mL and 10 glass beads are added. After sterilization, 3 mL of the spore suspension in step (1) was inserted, and the spore density was 1×10 6 / mL, and cultured at 30° C. and 150 rpm for 8 days.

[0047] (3) Solid-state fermentation of distiller's grains

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com