Amorphous cobalt-nickel-matrix chalcogenide film as well as preparation method and application thereof

A technology of chalcogenides and sulfides, which is applied in the field of solar cells, can solve the problem of less amorphous cobalt-nickel-based chalcogenides, and achieve the effects of low cost, easy availability of raw materials, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0040] Disperse 0.125 mmol of cobalt chloride hexahydrate, 0.125 mmol of nickel chloride hexahydrate and 50 mmol of thiourea in 50 mL of deionized water and stir evenly to obtain an electroplating solution. Take 1mL of analytically pure ammonia water and add it to 10mL of deionized water to make an ammonia solution. Add 0.13ml of ammonia solution to the electroplating solution to adjust the pH of the electroplating solution to 7.1; use the platinum mesh as the counter electrode, silver / silver chloride as the reference electrode, and ITO conductive glass as the working electrode. The deposition bias is -0.8 V, and the setting time is 10 s; the anode electrodeposition bias is 0.3 V, and the setting time is 20 s; the number of electroplating cycles is 20; the electroplating temperature is 35 °C; Amorphous cobalt-nickel-based sulfide films were obtained.

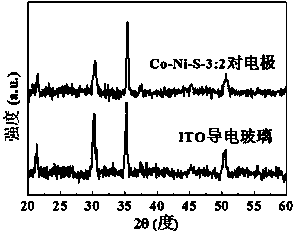

[0041] For ease of description, the Co-Ni-S film can be expressed as Co-Ni-S-x:y, where x refers to the amount of cobalt chlo...

Embodiment approach 2

[0044] Disperse 0.125 mmol of cobalt chloride hexahydrate, 0.125 mmol of nickel chloride hexahydrate and 50 mmol of thiourea in 50 mL of deionized water and stir evenly to obtain an electroplating solution. Add 0.17ml of ammonia solution to the electroplating solution to adjust the pH of the electroplating solution to 7.3; use the platinum mesh as the counter electrode, silver / silver chloride as the reference electrode, and ITO conductive glass as the working electrode. The deposition bias was -1.3 V, and the setting time was 5 s; the anode electrodeposition bias was 0.1 V, and the setting time was 25 s; the number of electroplating cycles was 5; the electroplating temperature was 10°C; Amorphous cobalt-nickel-based sulfide Co-Ni-S-1:1 film was obtained.

Embodiment approach 3

[0046] Disperse 0.125 mmol of cobalt chloride hexahydrate, 0.125 mmol of nickel chloride hexahydrate and 50 mmol of thiourea in 50 mL of deionized water and stir evenly to obtain an electroplating solution. Add 0.15ml of ammonia solution to the electroplating solution to adjust the pH of the electroplating solution to 7.2; use the platinum mesh as the counter electrode, silver / silver chloride as the reference electrode, and FTO conductive glass as the working electrode. The deposition bias was -1.2 V, and the setting time was 6 s; the anode electrodeposition bias was 0.2 V, and the setting time was 24 s; the number of electroplating cycles was 12; the electroplating temperature was 25°C; Amorphous cobalt-nickel-based sulfide Co-Ni-S-1:1 film was obtained.

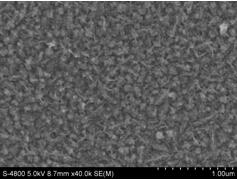

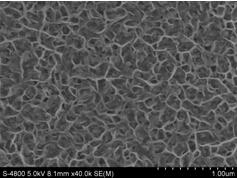

[0047] Such as figure 2 , SEM characterization of the Co-Ni-S-1:1 thin film prepared in this embodiment. From the SEM pictures, it can be clearly seen that the Co-Ni-S-1:1 film is composed of nanoparticles and nanoflakes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com