Single piezoelectric fiber filament and preparation method thereof

A piezoelectric fiber, a single technology, applied in the spinning field, can solve the problems of unsustainable power supply, small power supply capacity, etc., and achieve the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

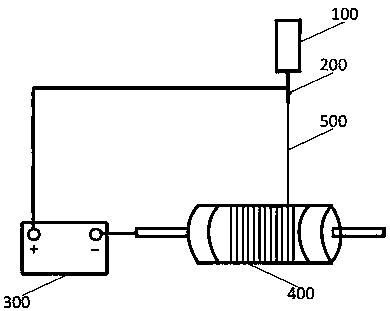

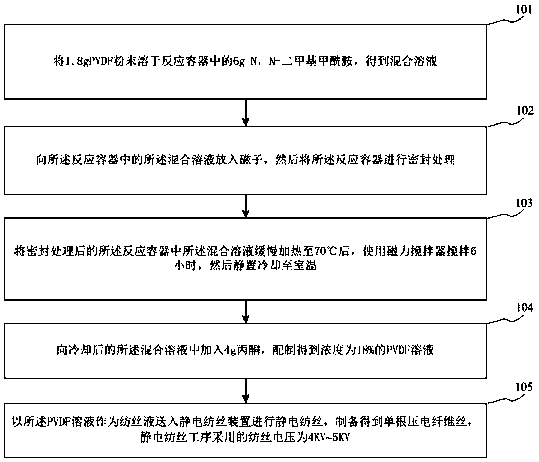

[0026] figure 1 It is a method flowchart of a method for preparing a single piezoelectric fiber shown according to an exemplary embodiment, such as figure 1 Shown, the preparation method of described piezoelectric fiber silk comprises:

[0027] Step 101, dissolving 1.8g of PVDF powder in 6g of N,N-dimethylformamide in a reaction vessel to obtain a mixed solution.

[0028] Step 102, putting magnets into the mixed solution in the reaction vessel, and then sealing the reaction vessel.

[0029] For example, the reaction container may be a reagent bottle, a three-necked flask or the like.

[0030] The operation of the sealing treatment may be to seal the container mouth of the reaction container with a plastic wrap, or to seal the container port of the reaction container with a sealing cap.

[0031] Step 103, slowly heating the mixed solution in the sealed reaction vessel to 70° C., stirring with a magnetic stirrer for 6 hours, and then standing to cool to room temperature.

[...

Embodiment 1

[0045]Weigh 1.8g of PVDF powder with a balance, and measure 6g of N,N-dimethylformamide (0.945-0.950g / ml) with a measuring cup, dissolve 1.8g of PVDF powder in 6g of N,N-dimethylformamide in the reagent bottle base formamide to obtain a mixed solution; put a magnet into the mixed solution in the reagent bottle, and then seal the reagent bottle; slowly heat the mixed solution in the sealed reagent bottle to 70°C, and use A magnetic stirrer was stirred for 6 hours, then left to cool to room temperature; 4g acetone (0.79g / ml) was added to the cooled mixed solution to prepare a PVDF solution with a concentration of 18%; the PVDF solution was used as a spinning solution. The silk liquid is sent to the electrospinning device for electrospinning, and a single piezoelectric fiber is prepared. The spinning voltage used in the electrospinning process is 4KV, and the spinning speed is 0.1mm / min. The single piezoelectric fiber is made of Roller collection, the receiving distance is 15mm, ...

Embodiment 2

[0047] Weigh 1.8g of PVDF powder with a balance, and measure 6g of N,N-dimethylformamide (0.945-0.950g / ml) with a measuring cup, dissolve 1.8g of PVDF powder in 6g of N,N-dimethylformamide in the reagent bottle base formamide to obtain a mixed solution; put a magnet into the mixed solution in the reagent bottle, and then seal the reagent bottle; slowly heat the mixed solution in the sealed reagent bottle to 70°C, and use A magnetic stirrer was stirred for 6 hours, then left to cool to room temperature; 4g acetone (0.79g / ml) was added to the cooled mixed solution to prepare a PVDF solution with a concentration of 18%; the PVDF solution was used as a spinning solution. The silk liquid is sent to the electrospinning device for electrospinning, and a single piezoelectric fiber is prepared. The spinning voltage used in the electrospinning process is 4.5KV, and the spinning speed is 0.1mm / min. Collected by the drum, the receiving distance is 15mm, the direction of the spinning elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com