Preparation method and application of nanometer nickel sulfide-graphene composite electrode material

A graphene composite and electrode material technology, applied in the field of electrochemistry, can solve problems such as single performance and cumbersome preparation of nickel sulfide composite materials, and achieve the effects of simplifying the synthesis steps, increasing dispersion and electrochemical activity, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

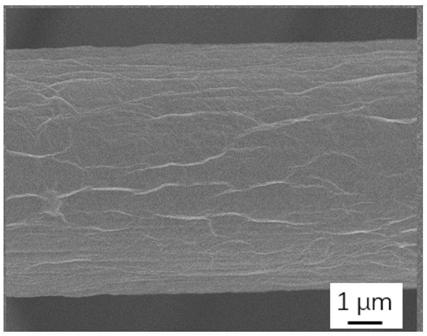

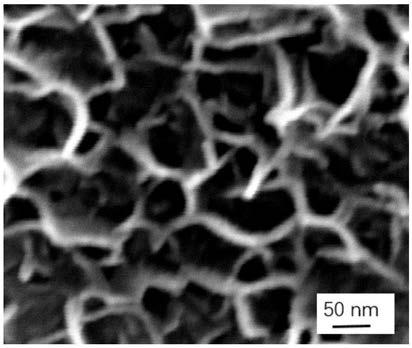

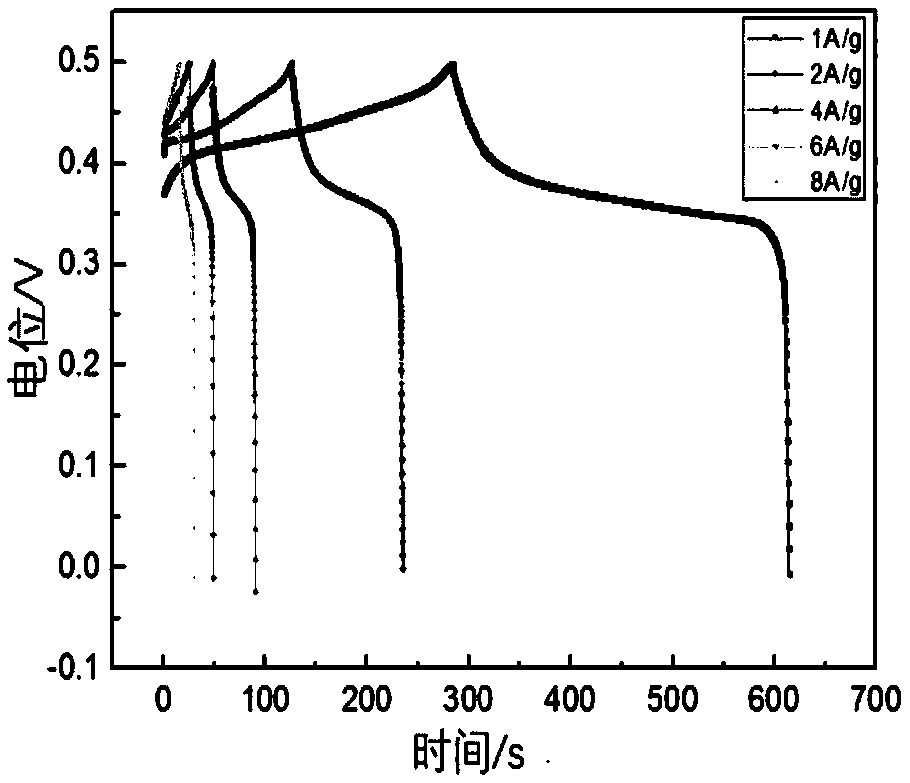

[0027] 1. Preparation of nano-nickel sulfide-graphene composite electrode materials

[0028] (1) Arrange clean 1cm*1cm carbon fibers in a 3mg / ml graphene oxide solution. After the surface of the carbon cloth is completely loaded with graphene oxide, take out the carbon cloth and dry it under vacuum at 60°C for 8 hours to obtain a concentration of about 1.6mg / cm 2 Graphene oxide / carbon fiber cloth of graphene oxide;

[0029] (2) Assembling a three-electrode system, using the graphene oxide / conductive carbon base obtained in step (1) as a working electrode, using 30mmol / L nickel chloride as an electrolyte, using a constant potential deposition method, the deposition potential is -1.1 V, the deposition time is 10min, depositing nano-nickel hydroxide on the surface of graphene / carbon fiber cloth realizes the electroreduction of graphene oxide, and obtains nickel hydroxide-graphene composite material;

[0030] (3) React 8 mg of nickel hydroxide-graphene composite material obtained...

Embodiment 2

[0037] 1. Preparation of nano-nickel sulfide-graphene composite electrode materials

[0038] (1) Arrange clean 1cm*1cm carbon fibers in a 2mg / ml graphene oxide solution. After the surface of the carbon cloth is completely loaded with graphene oxide, take out the carbon cloth and dry it under vacuum at 50°C for 10 hours to obtain a concentration of about 1mg / cm 2 Graphene oxide / carbon fiber cloth of graphene oxide;

[0039] (2) Assembling a three-electrode system, using the graphene oxide / conductive carbon base obtained in step (1) as the working electrode, using 20mmol / L nickel nitrate as the electrolyte, using the constant potential deposition method, the deposition potential is -1.0V , the deposition time is 20min, while depositing nano-nickel hydroxide on the surface of graphene / carbon fiber cloth, the electroreduction of graphene oxide is realized to obtain nickel hydroxide-graphene composite material;

[0040] (3) React 5 mg of nickel hydroxide-graphene composite materia...

Embodiment 3

[0046] 1. Preparation of nano-nickel sulfide-graphene composite electrode materials

[0047] (1) Arrange clean 1cm*1cm carbon fibers in a 4mg / ml graphene oxide solution. After the surface of the carbon cloth is completely loaded with graphene oxide, take out the carbon cloth and dry it under vacuum at 70°C for 6 hours to obtain a concentration of about 2mg / cm 2 Graphene oxide / carbon fiber cloth of graphene oxide;

[0048] (2) Assembling a three-electrode system, using the graphene oxide / conductive carbon base obtained in step (1) as the working electrode, using 40mmol / L of nickel sulfate as the electrolyte, using the constant potential deposition method, the deposition potential is -1.2V , the deposition time is 15min, while depositing nano-nickel hydroxide on the surface of graphene / carbon fiber cloth, the electroreduction of graphene oxide is realized to obtain nickel hydroxide-graphene composite material;

[0049] (3) React 10 mg of nickel hydroxide-graphene composite obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com