Preparation method of porous graphene/transition metal chalcogenide film

A technology of chalcogenides and transition metals, which is applied in the field of preparation of porous graphene/transition metal chalcogenides thin films, can solve the problems of fragile structure, poor physical properties, and reduced electrochemical stability of materials, so as to achieve rate performance Improvement, good electrochemical stability, stable and efficient utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Preparation of MoS by ion intercalation method 2 Dispersion, MoS 2 / Preparation of graphene (1:1) porous film electrodes

[0022] Preparation of MoS by lithium ion intercalation method 2 Dispersions. Weigh 500mgMoS 2 Disperse in 100 mL of cyclohexane, and raise the mixed solution to 80° C. under a nitrogen atmosphere. At this point, 10 mL of butyllithium was added and reacted at 90° C. for three days. The powder obtained by suction filtration after cooling was placed in ultrapure water for 90 minutes and subjected to centrifugation for 3 times to obtain MoS 2 Dispersions.

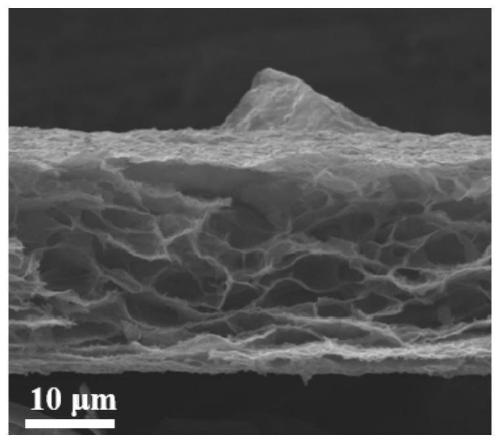

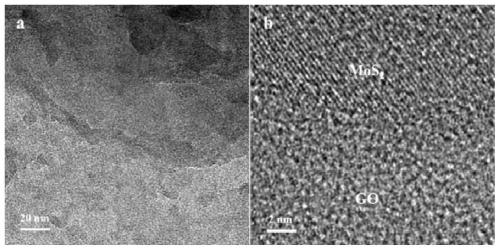

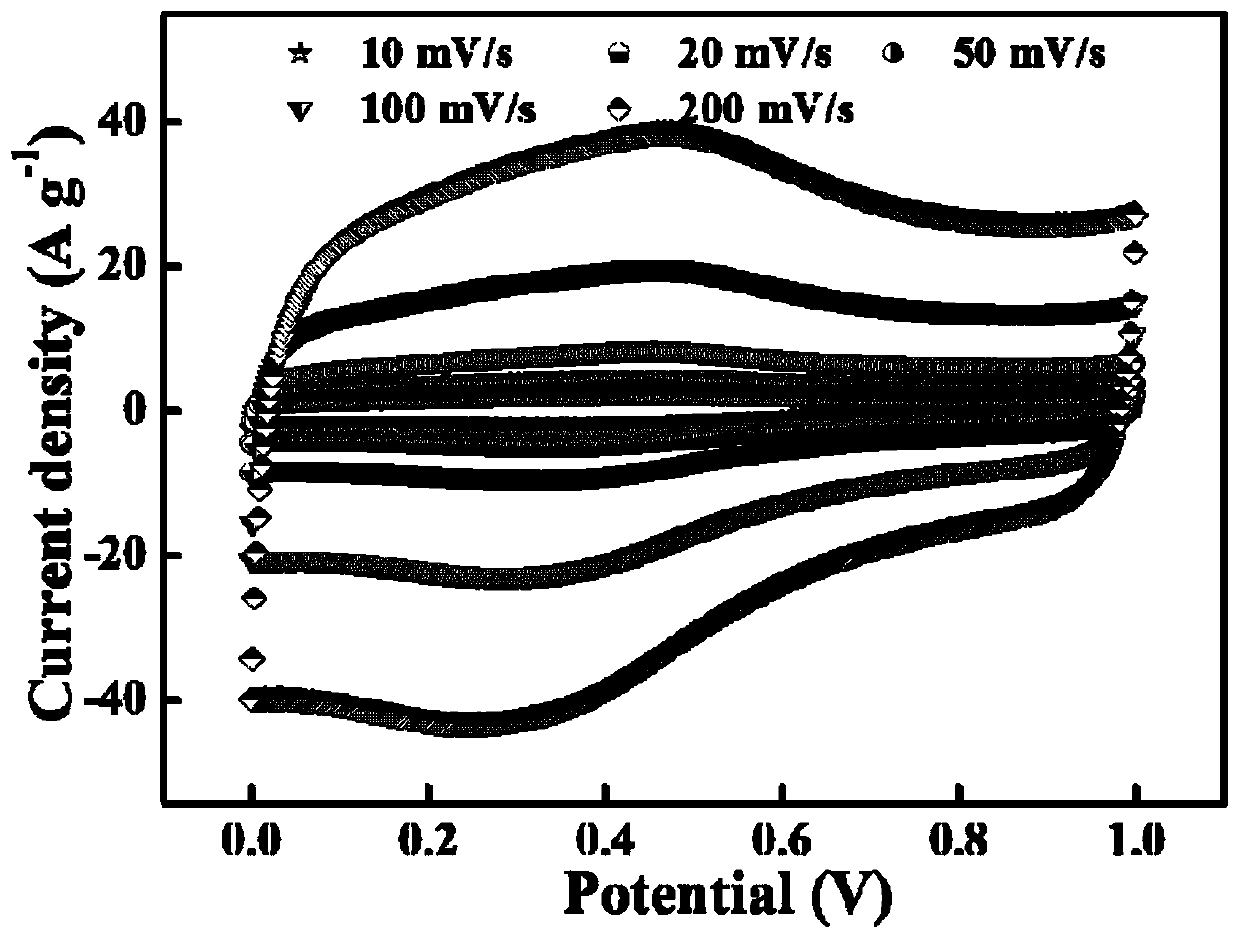

[0023] MoS 2 Dispersion and 5mg mL -1 The graphene dispersion was mixed uniformly at a mass ratio of 1:1, ultrasonicated in a water bath for 30 minutes, and the amount of residual moisture was controlled to 10% by vacuum filtration, and a preliminary sample was obtained in combination with a freeze-drying method. The sample was placed in the center of the tube furnace, and the temp...

Embodiment 2

[0025] Example 2 Preparation of MoS by Ultrasonic Degradation 2 Dispersion, MoS 2 / Preparation of graphene (1:1) porous film electrodes

[0026] Preparation of MoS by Ultrasonic Degradation 2 Dispersions. Weigh 500mgMoS 2 Disperse in 50ml of N,N-dimethylformamide solution, and disperse the mixture by tip ultrasonic method. After ultrasonication, the mixture was left to stand for 24 hours, then the upper layer was taken and centrifuged three times with a centrifuge to obtain MoS 2 Dispersions.

[0027] MoS 2 Dispersion and 5mg mL -1 The graphene dispersion was mixed evenly at a mass ratio of 1:1, ultrasonicated in a water bath for 30 minutes, and a preliminary sample was obtained by vacuum filtration combined with freeze-drying. The sample was placed in the center of the tube furnace, and the temperature was raised to 400°C for 1 hour in a mixed atmosphere of high-purity argon and hydrogen to prepare porous graphene / MoS 2 Film (Sample 2).

[0028] The preparation proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com