A T-type rectifying circuit and a corresponding three-phase rectifying circuit

A technology of rectifier circuit and rectifier diode, which is applied in the direction of high-efficiency power electronic conversion, conversion of AC power input to DC power output, electrical components, etc., can solve problems such as increasing the difficulty of circuit design, reducing system stability, and noise pollution of power devices. It is beneficial to the electrical layout and structural design, reduces the amount of EMI electromagnetic interference, and has the effect of compact circuit topology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

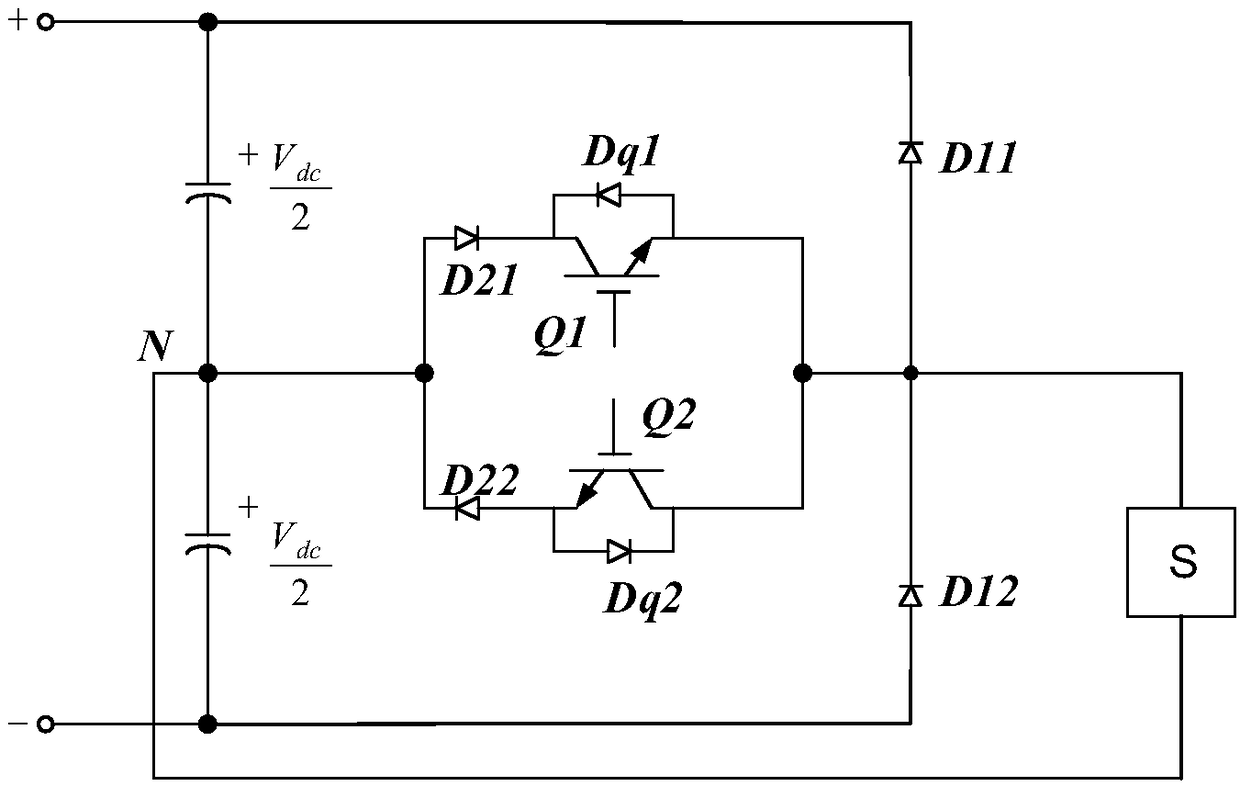

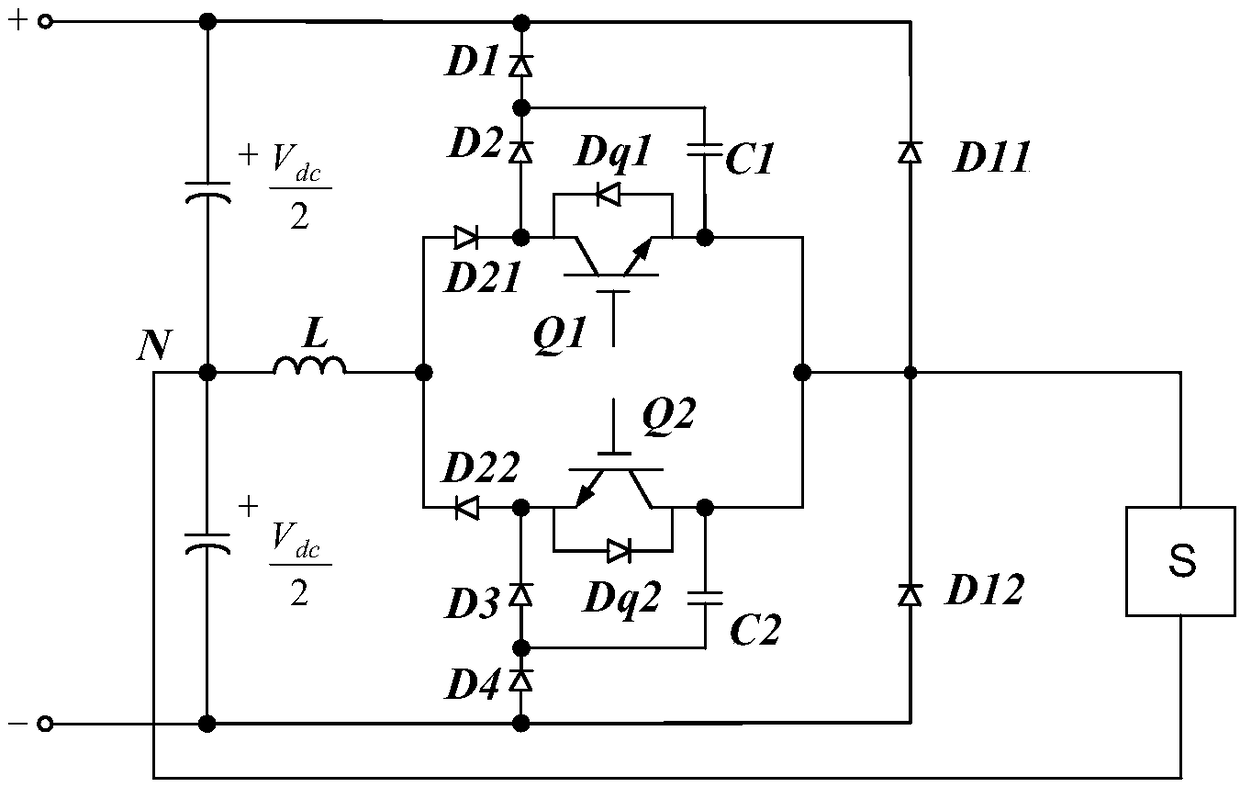

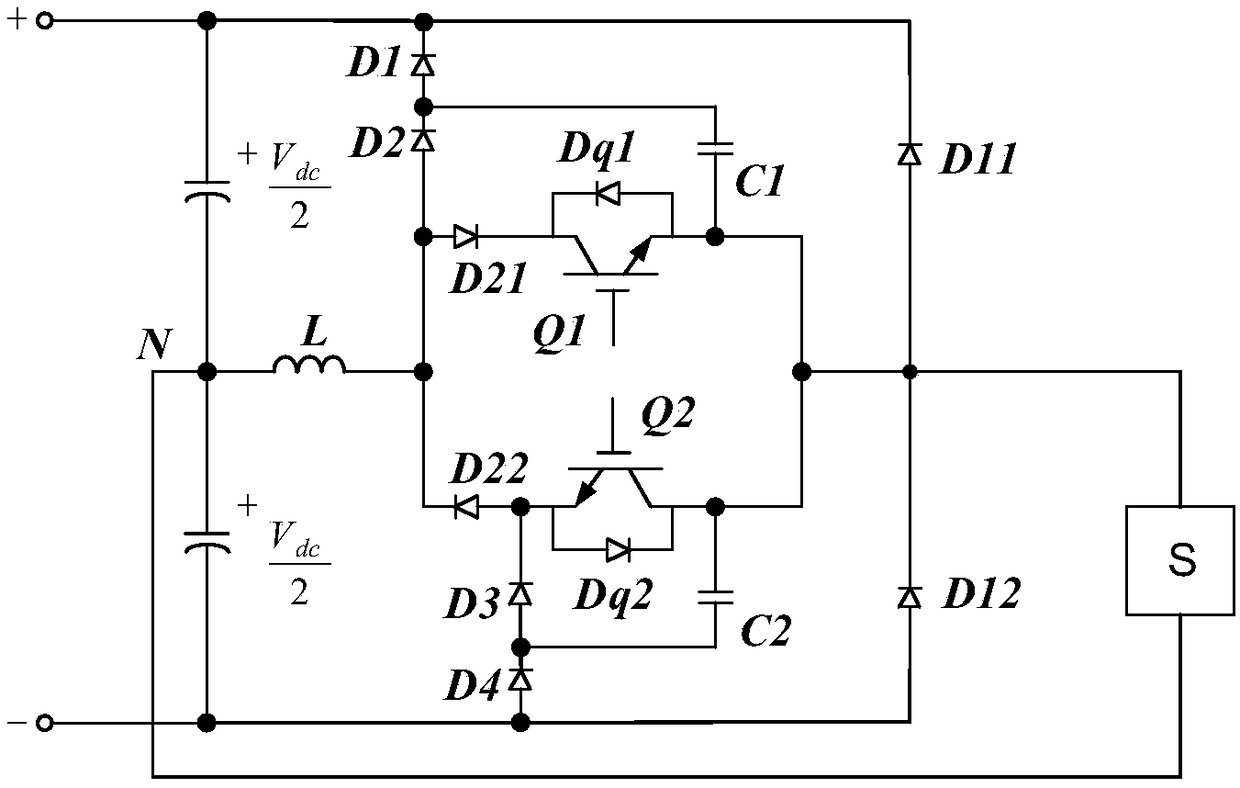

[0045] The core of the present invention is to provide a T-shaped rectifier circuit and a corresponding three-phase rectifier circuit, which uses the internal circuit topology to enable the first controllable switch and the second controllable switch to realize soft switching, thereby reducing the need for controllable switches. On-off power consumption; moreover, devices can be added without changing the internal circuit layout of the traditional T-type rectifier circuit, so that the circuit topology is compact and the busbar design is simple, which is conducive to electrical layout and structural design, and Retrofit costs are reduced.

[0046] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com