Method for preparing medical collagen sponge

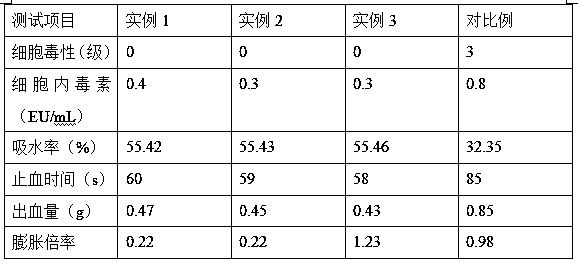

A collagen sponge and a technology for preparation steps, which are applied in the field of preparation of medical collagen sponges, can solve the problems of limited effect of absorbing hemorrhage and exudate, water-absorbing swelling performance to be improved, poor anti-infection performance, etc., so as to improve medical performance and Physiological activity, the effect of improving solubility and degradability, improving flexibility and absorbency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Take 6-10g of sodium alginate and add it to a beaker filled with 200-250mL of deionized water, stir with a magnetic stirrer at a speed of 500-550r / min until the sodium alginate dissolves, and obtain a mass fraction of 2-4% alginic acid Sodium solution, dissolve 3-4g of sodium periodate in 10-12g of deionized water to obtain an oxidation solution; put the above-mentioned oxidation solution into a three-necked flask with a dropping funnel and a stirrer, start the stirrer, and use 300- Start stirring at a speed of 500r / min, then put the above-mentioned sodium alginate solution into the dropping funnel, add the sodium alginate solution dropwise into the three-necked flask at a dropping rate of 4-6mL / min, after the addition is completed, put the three-necked Place the flask under light-proof conditions, and react at room temperature for 20-24 hours to obtain oxidized sodium alginate; add 4-5 mL of ethylene glycol to the above-mentioned oxidized sodium alginate, stop the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com