UiO-66-NH2/TiO2/Ti3C2 composite photocatalyst with efficient hydrogen production and preparation method thereof

A uio-66-nh2, composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problem of narrow photoresponse range, low quantum yield, photogenerated electron-hole pairs The problem of high recombination probability can achieve the effect of improving separation efficiency, simple process and improving light absorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

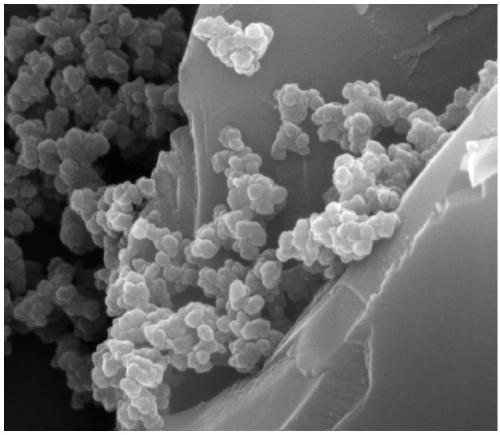

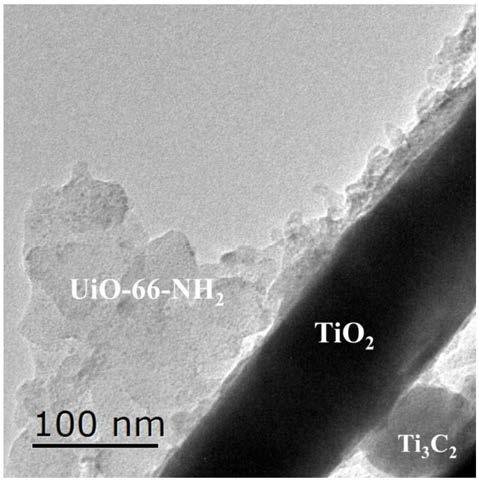

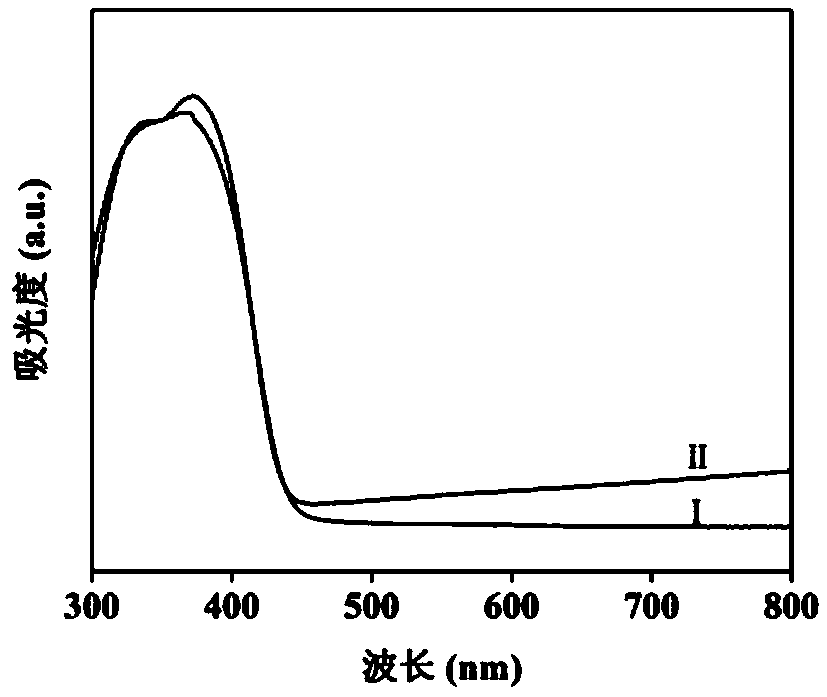

[0031] A UiO-66-NH with Efficient Hydrogen Production 2 / TiO 2 / Ti 3 C 2 Composite photocatalyst and preparation method thereof. The steps of the preparation method are:

[0032] Step 1. Press Ti 3 AlC 2 : The molar ratio of hydrofluoric acid is 1: (40~45), first the Ti 3 AlC 2 Place it in a polytetrafluoroethylene lining, add hydrofluoric acid solution, stir for 24-30 hours, then alternately wash with deionized water and absolute ethanol for 5-8 times, centrifuge, and dry to obtain Ti 3 C 2 T x .

[0033] Step 2, the Ti 3 C 2 T x Put it in a crucible, and anneal it under a nitrogen atmosphere. The annealing temperature is 400-500°C, and the annealing time is 2-2.5h to obtain TiO 2 / Ti 3 C 2 Complex.

[0034] Step 3, according to the molar ratio of zirconium tetrachloride:N,N-dimethylformamide:hydrochloric acid is 1:10:60, the zirconium tetrachloride, the N,N-dimethylformamide and The hydrochloric acid was mixed and ultrasonically treated for 2-3 minutes to o...

Embodiment 2

[0044] A UiO-66-NH with Efficient Hydrogen Production 2 / TiO 2 / Ti 3 C2 Composite photocatalyst and preparation method thereof. The steps of the preparation method are:

[0045] Step 1. Press Ti 3 AlC 2 : The molar ratio of hydrofluoric acid is 1: (45~50), firstly the Ti 3 AlC 2 Put it in a polytetrafluoroethylene lining, then add hydrofluoric acid solution, stir for 30-36 hours, then alternately wash with deionized water and absolute ethanol for 5-8 times, centrifuge, and dry to obtain Ti 3 C 2 T x .

[0046] Step 2, the Ti 3 C 2 T x Put it in a crucible, and anneal it under a nitrogen atmosphere. The temperature of the annealing treatment is 500-600°C, and the time of the annealing treatment is 2.5-3 hours to obtain TiO 2 / Ti 3 C 2 Complex.

[0047] Step 3, according to the molar ratio of zirconium tetrachloride:N,N-dimethylformamide:hydrochloric acid is 1:10:60, the zirconium tetrachloride, the N,N-dimethylformamide and The hydrochloric acid was mixed and u...

Embodiment 3

[0054] A UiO-66-NH with Efficient Hydrogen Production 2 / TiO 2 / Ti 3 C 2 Composite photocatalyst and preparation method thereof. The steps of the preparation method are:

[0055] Step 1. Press Ti 3 AlC 2 : The molar ratio of hydrofluoric acid is 1: (50~55), first the Ti 3 AlC 2 Place it in a polytetrafluoroethylene lining, add hydrofluoric acid solution, stir for 36-42 hours, then alternately wash with deionized water and absolute ethanol for 5-8 times, centrifuge, and dry to obtain Ti 3 C 2 T x .

[0056] Step 2, the Ti 3 C 2 T x Put it in a crucible, and anneal it under a nitrogen atmosphere. The temperature of the annealing treatment is 600-700°C, and the time of the annealing treatment is 3-3.5 hours to obtain TiO 2 / Ti 3 C 2 Complex.

[0057] Step 3, according to the molar ratio of zirconium tetrachloride:N,N-dimethylformamide:hydrochloric acid is 1:10:60, the zirconium tetrachloride, the N,N-dimethylformamide and The hydrochloric acid was mixed and ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com