Organic acid treatment method for isopropanol aluminum waste catalyst and device thereof

A technology of aluminum isopropoxide and waste catalyst, which is applied in the field of chemical technology, can solve problems such as blockage of pipelines and storage containers, loss of useful substances, easy moisture absorption, etc., and achieve the effects of avoiding environmental protection problems, ensuring repeated use, and increasing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

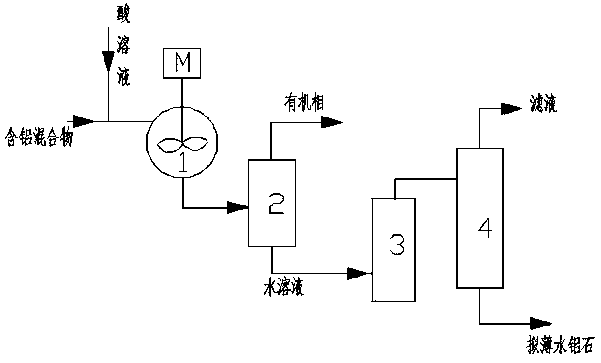

Image

Examples

Embodiment 1

[0025] Take 50g of the mixed product and 200g of acetic acid solution (wt%: 5%) for mixing and stirring. After stirring evenly, let it stand for stratification. The mass of the upper organic oil phase is 47g, and the lower layer contains 201g of aluminum-containing aqueous phase. The lower aqueous phase was flocculated and precipitated by heating, and the precipitate was filtered and dried to obtain 11.23 g of pseudo-boehmite powder.

Embodiment 2

[0027] Take 50g of the mixed product and 100g of acetic acid solution (wt%: 10%) for mixing and stirring. After stirring evenly, let it stand for stratification. The mass of the upper organic oil phase is 48g, and the lower layer contains 101g of aluminum-containing aqueous phase. The lower aqueous phase was flocculated and precipitated by heating, and the precipitate was filtered and dried to obtain 11.19 g of pseudo-boehmite powder.

Embodiment 3

[0029] Take 50g of the mixed product and 67g of acetic acid solution (wt%: 15%) for mixing and stirring. After stirring evenly, let it stand for stratification. The mass of the upper organic oil phase is 47g, and the lower aluminum-containing aqueous phase is 69g. The lower aqueous phase was flocculated and precipitated by heating, and the precipitate was filtered and dried to obtain 11.27 g of pseudo-boehmite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com