A kind of waterborne acrylic resin and its application

A water-based acrylic and resin technology, applied in the direction of coating, etc., can solve the problems of easy hydrolysis, fast degradation and aging of paint film, poor alkali resistance and anti-ultraviolet performance, and achieve aging degradation delay, good anti-ultraviolet performance, and improved The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

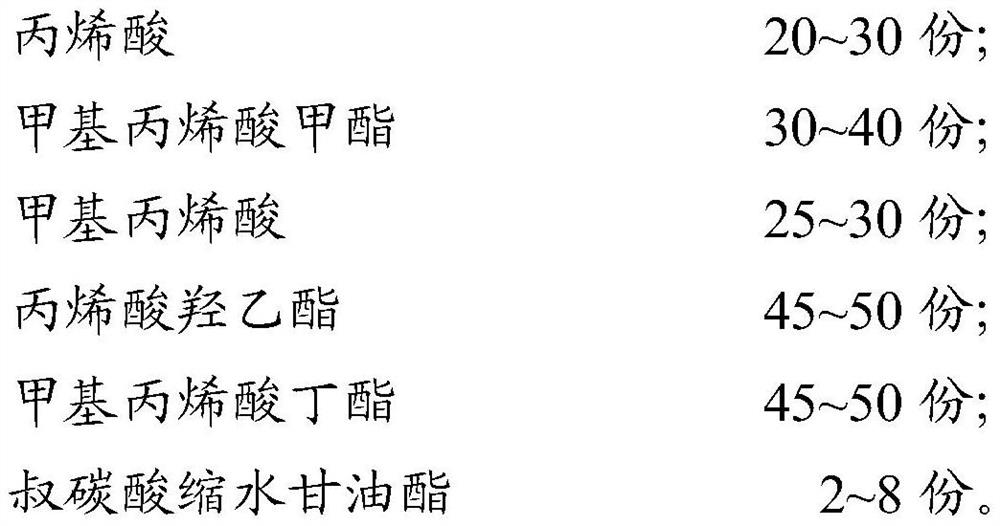

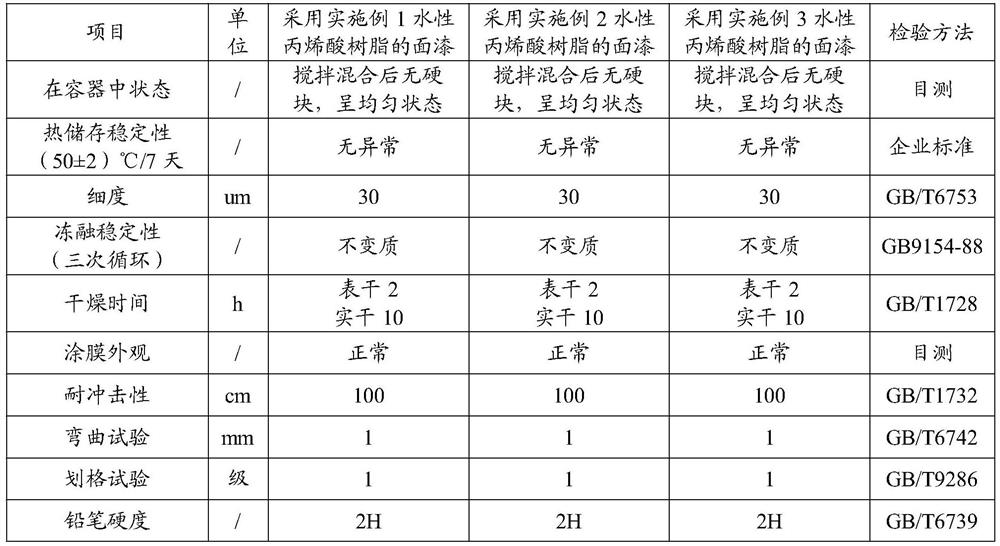

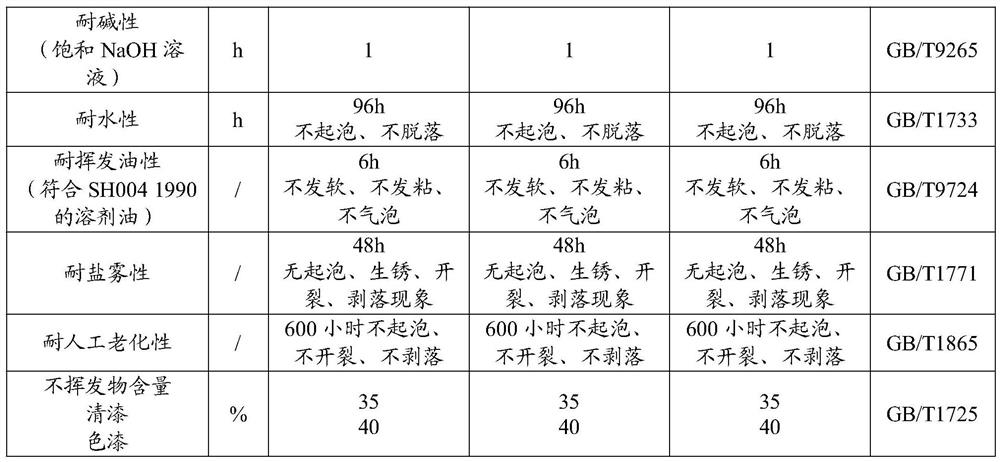

Embodiment 1

[0044] 20g of acrylic acid, 30g of methyl methacrylate, 25g of methacrylic acid, 45g of hydroxyethyl acrylate, 45g of butyl methacrylate, 10g of vinyltrimethoxysilane, 2g of benzoyl peroxide and 2g of glycidyl tert-carbonate Mix and stir to obtain a mixture. Put 50g of propylene glycol methyl ether into a four-necked flask, raise the temperature to 95°C, add 40g of the above mixture into it, and pre-react at 95°C for 30min. Add the rest of the above mixture dropwise in 2.5 hours; after the dropwise addition, keep warm for 2 hours; add 0.4g benzoyl peroxide and 20g propylene glycol methyl ether, keep warm for 2 hours (the reaction temperature is always 95°C); measure the acid value, acid value is about 50, and after cooling to 65°C, neutralize with a calculated amount of N-N dimethylethanolamine; finally add a certain amount of water and propylene glycol methyl ether to dilute the neutralized product to obtain a water-based acrylic resin (solid content 50wt%, Propylene glycol ...

Embodiment 2

[0046] 25g of acrylic acid, 35g of methyl methacrylate, 30g of methacrylic acid, 50g of hydroxyethyl acrylate, 48g of butyl methacrylate, 15g of vinyltrimethoxysilane, 5g of benzoyl peroxide and 8g of glycidyl tert-carbonate Mix and stir to obtain a mixture. Put 80g of propylene glycol methyl ether into a four-neck flask, raise the temperature to 100°C, add 40g of the above mixture into it, and pre-react at 100°C for 45min. Add the rest of the above mixture dropwise in 2 hours; after the dropwise addition, keep warm for 2 hours; add 0.6g benzoyl peroxide and 25g propylene glycol methyl ether, keep warm for 2 hours (the reaction temperature is always 100°C); measure the acid value, the acid value is 50 or so, after cooling down to 65°C, neutralize with a calculated amount of N-N dimethylethanolamine; finally add a certain amount of water and propylene glycol methyl ether to dilute the neutralized product to obtain a water-based acrylic resin (solid content 50wt%, propylene glyc...

Embodiment 3

[0048] 30g of acrylic acid, 40g of methyl methacrylate, 28g of methacrylic acid, 47g of hydroxyethyl acrylate, 50g of butyl methacrylate, 12g of vinyltrimethoxysilane, 8g of benzoyl peroxide and 5g of glycidyl tert-carbonate Mix and stir to obtain a mixture. Put 100g of propylene glycol methyl ether into a four-neck flask, raise the temperature to 105°C, add 40g of the above mixture into it, and pre-react at 105°C for 60min. Add the rest of the above mixture dropwise in 1.5 hours; after the dropwise addition, keep warm for 2 hours; add 0.8g benzoyl peroxide and 30g propylene glycol methyl ether, keep warm for 2 hours (the reaction temperature is always 105°C); measure the acid value, acid value is about 50, and after cooling to 65°C, neutralize with a calculated amount of N-N dimethylethanolamine; finally add a certain amount of water and propylene glycol methyl ether to dilute the neutralized product to obtain a water-based acrylic resin (solid content 50wt%, Propylene glyco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com