Mobile phone protection film preparation method

A technology of protective film and mobile phone, which is applied in the field of preparation of mobile phone protective film, can solve the problems of dust-absorbing mobile phone screen, general anti-static effect, and poor anti-static durability, so as to improve anti-static effect, improve mechanical properties and durability Grinding performance, enhanced compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

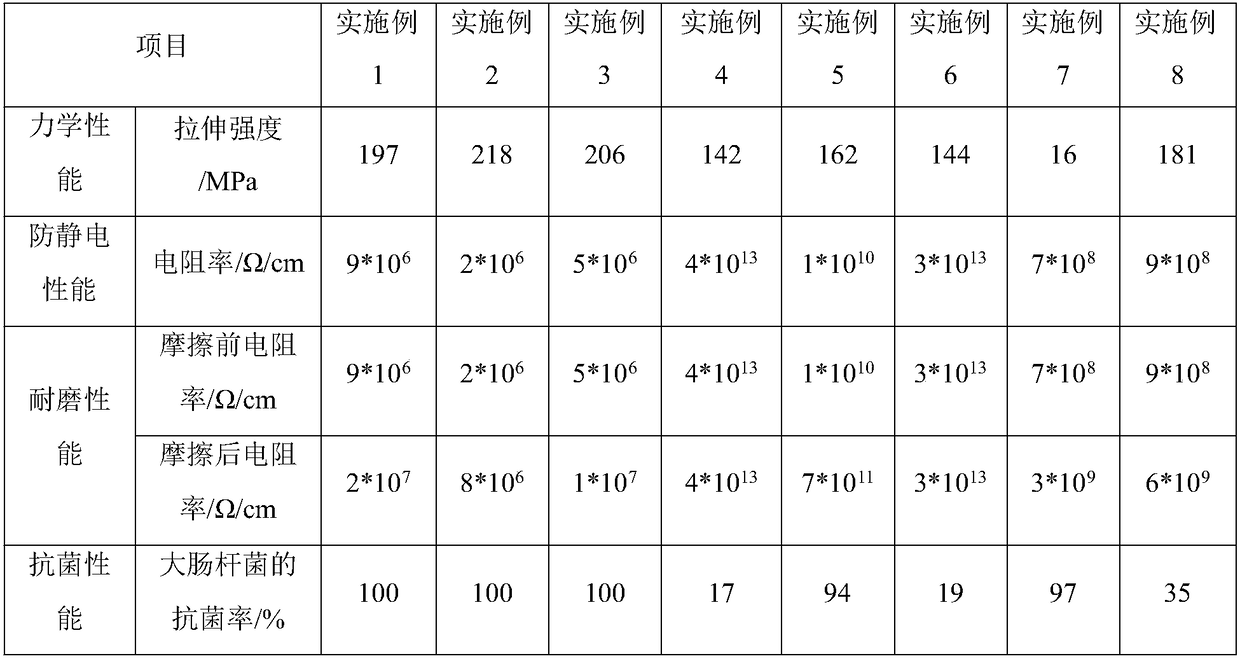

Examples

preparation example Construction

[0019] The embodiment of the present invention provides a method for preparing a mobile phone protective film, comprising the following steps: extruding and granulating 80-100 parts by weight of a polyester masterbatch and 10-20 parts by weight of a functional filler to obtain a functional masterbatch. The filler is polyaniline-coated graphene and modified zinc oxide particles; the polyester base material and the functional masterbatch are melt-extruded, cast, stretched, heat-treated, and cut to obtain a mobile phone protective film. The functional masterbatch is obtained by extruding and granulating 80-100 parts by weight of polyester masterbatch and 10-20 parts by weight of functional filler, preferably by aniline monomer soap-free emulsion polymerization.

[0020] As a preferred version, the modified zinc oxide is prepared according to the following method: Zn(N0 3 ) 2 and FeS0 4 After mixing according to a certain molar ratio, quickly add oxalic acid, and stir in a water...

Embodiment 1

[0033] A mobile phone protective film is prepared from 100 parts by weight of polyester base material FG600 and 20 parts by weight of functional masterbatch through melt extrusion, cast casting, stretching and setting, heat treatment and cutting.

[0034] The functional masterbatch is obtained by extruding and granulating 100 parts by weight of polyester masterbatch FG610 and 10 parts by weight of functional filler. The specific preparation method is as follows:

[0035] (1) Place polyester masterbatches and functional fillers in corresponding parts by weight in a vacuum drying oven and dry at 100°C for 6 hours;

[0036] (2) Put the dried slices and functional fillers into the internal mixer of the torque rheometer and blend for 0.5h, and the blending temperature is 260°C;

[0037] (3) Extrude in a twin-screw extruder and pelletize to obtain a functional masterbatch. The extrusion process conditions are: screw temperature 230°C in zone 1, 240°C in zone 2, 250°C in zone 3, 260°...

Embodiment 2

[0049] A mobile phone protective film is prepared from 100 parts by weight of polyester base material FG604 and 25 parts by weight of functional masterbatch through melt extrusion, cast casting, stretching and setting, heat treatment and cutting.

[0050] The functional masterbatch is obtained by extruding and granulating 80 parts by weight of polyester masterbatch FG612 and 10 parts by weight of functional filler. The specific preparation method is as follows:

[0051] (1) Put the polyester masterbatch and functional fillers in corresponding parts by weight in a vacuum drying oven and dry at 120°C for 6 hours;

[0052] (2) Put the dried slices and functional fillers into the internal mixer of the torque rheometer and blend for 2 hours, and the blending temperature is 250°C;

[0053] (3) Extrude in a twin-screw extruder and pelletize to obtain a functional masterbatch. The extrusion process conditions are: screw temperature 235°C in zone 1, 245°C in zone 2, 260°C in zone 3, 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com