Silane cross-linked polyaryletherketone anion exchange membrane and preparation method thereof

An anion-exchange membrane and polyaryletherketone technology, applied in the field of silane-crosslinked polyaryletherketone anion-exchange membrane and its preparation, can solve the problems of high water absorption, poor alkali resistance, membrane swelling and dissociation, etc. Achieve high electrical conductivity, good dimensional stability, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

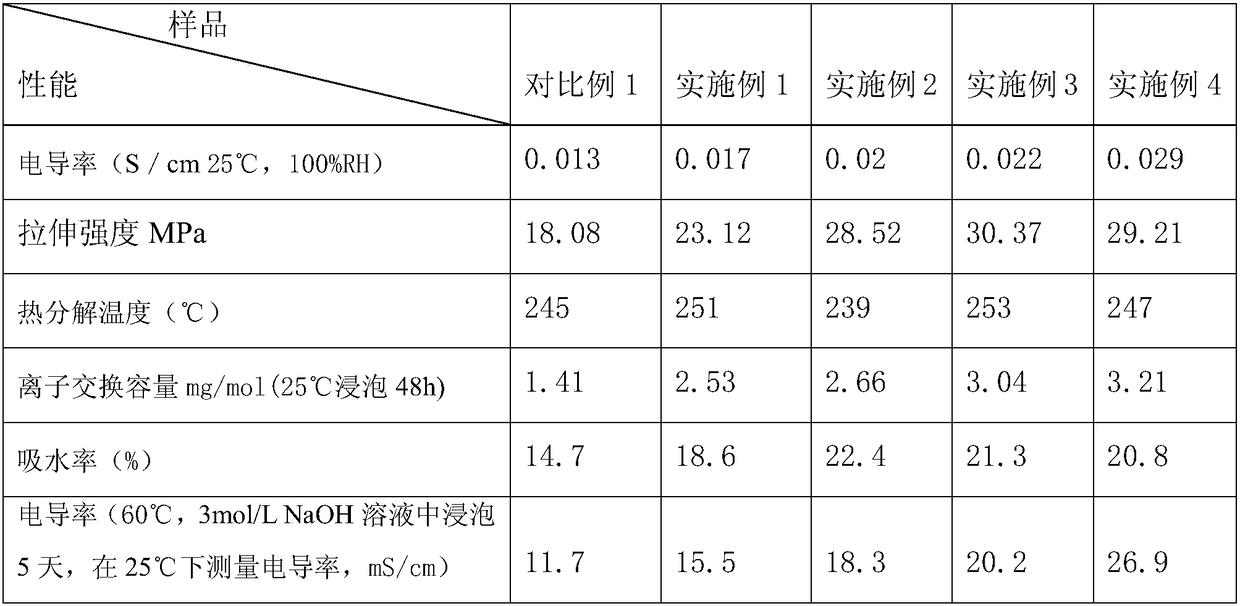

Examples

Embodiment 1

[0035] A siloxane crosslinked polyaryletherketone anion exchange membrane, the preparation method steps are as follows:

[0036] 3.27g 4,4'-difluorobenzophenone (DFBP), 3.63g 3,3',5,5'-tetramethylbiphenyl-4,4'-diol (TMbP) and 3.30g Anhydrous K 2 CO 3 Add it into a three-necked flask filled with 20mL sulfolane, dissolve to obtain a homogeneous solution, and under the protection of nitrogen, raise the temperature of the obtained solution to 130°C, keep it warm for 4h, then raise the temperature to 180°C and heat until the solution becomes viscous, and the viscous solution Pour it into water, dry the obtained precipitate and crush it with a dry powder crusher to obtain a polymer powder, then add the polymer powder to deionized water and boil it, filter it with suction and place it in an oven at 100°C to dry for 24 hours to obtain a polyaryletherketone polymer powder .

[0037] Add 3.88g of the above-mentioned dried polyaryletherketone polymer powder, 1.78g of NBS and 0.24g of ...

Embodiment 2

[0040] A siloxane crosslinked polyaryletherketone anion exchange membrane, the preparation method steps are as follows:

[0041] 3.27g 4,4'-difluorobenzophenone (DFBP), 3.63g 3,3',5,5'-tetramethylbiphenyl-4,4'-diol (TMbP) and 3.30g Anhydrous K 2 CO 3 Add it into a three-necked flask filled with 20mL sulfolane, dissolve to obtain a homogeneous solution, and under the protection of nitrogen, raise the temperature of the obtained solution to 140°C, keep it warm for 6h, then heat up to 200°C until the solution becomes viscous, and the viscous solution Pour it into water, dry the obtained precipitate and crush it with a dry powder crusher to obtain a polymer powder, then add the polymer powder to deionized water and boil it, filter it with suction and place it in an oven at 100°C to dry for 24 hours to obtain a polyaryletherketone polymer powder .

[0042] Add 3.88g of the above-mentioned dried polyaryletherketone polymer powder, 1.78g of NBS and 0.24g of BPO into a three-necked...

Embodiment 3

[0045] A siloxane crosslinked polyaryletherketone anion exchange membrane, the preparation method steps are as follows:

[0046] 3.27g 4,4'-difluorobenzophenone (DFBP), 3.63g 3,3',5,5'-tetramethylbiphenyl-4,4'-diol (TMbP) and 3.30g Anhydrous K 2 CO 3 Add it into a three-necked flask filled with 20mL sulfolane, dissolve to obtain a homogeneous solution, and under the protection of nitrogen, raise the temperature of the obtained solution to 150°C, keep it warm for 4h, then heat up to 180°C until the solution becomes viscous, and the viscous solution Pour it into water, dry the obtained precipitate and crush it with a dry powder crusher to obtain a polymer powder, then add the polymer powder to deionized water and boil it, filter it with suction and place it in an oven at 80°C to dry for 36 hours to obtain a polyaryletherketone polymer powder .

[0047] Add 3.88g of the above-mentioned dried polyaryletherketone polymer powder, 1.78g of NBS and 0.24g of BPO into a three-necked ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com