Graphene heat conductive coating modified radiator

A thermal conductive coating, graphene technology, applied in coatings, heat exchange materials, anti-corrosion coatings, etc., can solve problems such as poor anti-corrosion performance, general heat dissipation performance of heat dissipation fins, and limited application of water heaters, and achieve excellent thermal conductivity. , good thermal conductivity and heat dissipation effect, the effect of enhancing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

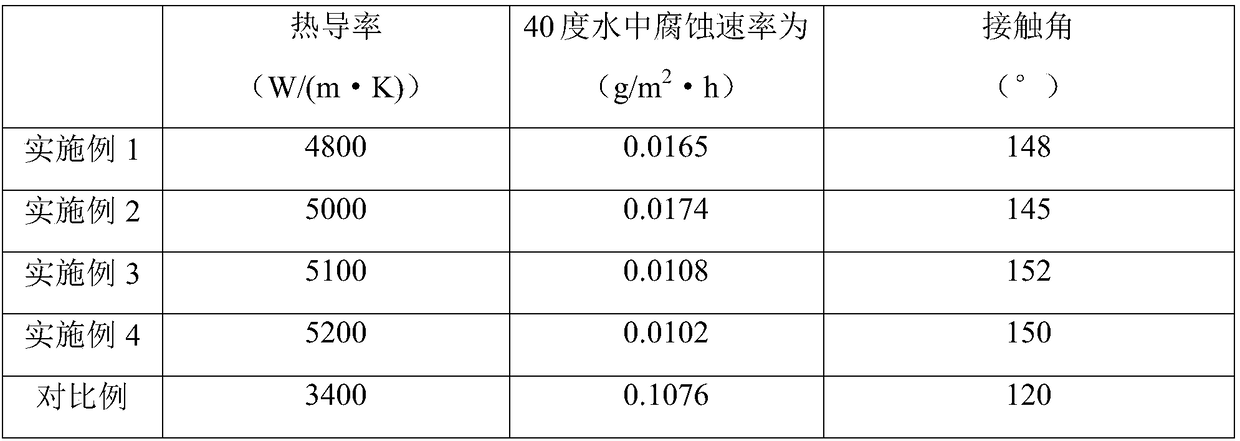

Examples

Embodiment 1

[0024] A heat sink modified by a graphene thermal conductive coating, comprising a heat dissipation base and a heat dissipation scale, the outer surface of the heat dissipation scale is sprayed with a graphene coating, and the composition of the graphene coating includes graphene oxide, water, tetrahydrofuran , water-based epoxy resin, methyl cellulose, composite conductive agent, carbon fiber filler, nano-scale silica and low surface energy organic matter.

[0025] In the composition of the graphene coating, the composite conductive agent is a mixture of acetylene carbon black, Ketjen black and carbon nanotubes, wherein the mass ratio of acetylene carbon black, Ketjen black and carbon nanotubes is 1:1:2.

[0026] Further, the heat dissipation base and the heat dissipation scales are made of one or more alloy materials of metal copper, metal aluminum, metal iron, and metal silver.

[0027] The spraying process of the graphene coating on the heat dissipation flakes comprises th...

Embodiment 2

[0034] A heat sink modified by a graphene thermal conductive coating, comprising a heat dissipation base and a heat dissipation scale, the outer surface of the heat dissipation scale is sprayed with a graphene coating, and the composition of the graphene coating includes graphene oxide, water , tetrahydrofuran, modified urea-formaldehyde resin, sodium alginate, composite conductive agent, carbon fiber filler, nano-scale silica and low surface energy organic matter.

[0035] In the composition of the graphene coating, the composite conductive agent is a mixture of acetylene carbon black, Ketjen black and carbon nanotubes, wherein the mass ratio of acetylene carbon black, Ketjen black and carbon nanotubes is 1:1:2.

[0036] The spraying process of the graphene coating on the heat dissipation flakes comprises the following steps:

[0037] Step 1): 5 parts by mass of graphene are added to 50 parts by mass of water, and the graphene is uniformly dispersed in the aqueous system and ...

Embodiment 3

[0043] A heat sink modified by a graphene thermal conductive coating, comprising a heat dissipation base and a heat dissipation scale, the outer surface of the heat dissipation scale is sprayed with a graphene coating, and the composition of the graphene coating includes graphene oxide, water , tetrahydrofuran, water-based acrylic resin, agar, composite conductive agent, carbon fiber filler, nano-scale silica and low surface energy organic matter.

[0044] In the composition of the graphene coating, the composite conductive agent is a mixture of acetylene carbon black, Ketjen black and carbon nanotubes, wherein the mass ratio of acetylene carbon black, Ketjen black and carbon nanotubes is 1:1:2.

[0045] The spraying process of the graphene coating on the heat dissipation flakes comprises the following steps:

[0046] Step 1): 5 parts by mass of graphene are added to 50 parts by mass of water, and the graphene is uniformly dispersed in the aqueous system and part of the graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com