Continuous reactor for oleic acid ester exchange reaction and purifying method of fatty acid diglyceride

A technology of transesterification reaction and purification method, which is applied in the continuous reactor of oil transesterification reaction and the field of fatty acid diglyceride purification, can solve the problems of small output, low reaction yield, low efficiency and the like, and achieves a high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

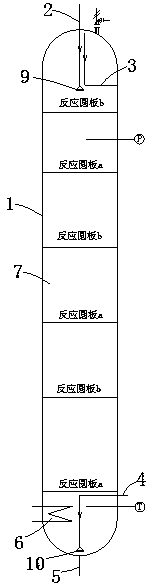

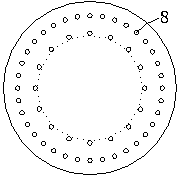

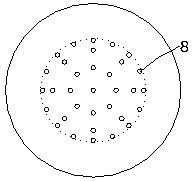

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of continuous reactor of fat transesterification reaction, comprises reactor body 1, is provided with catalyst solution feeding pipe 2 at the top of reactor body 1, and the top of reactor body 1 is provided with reaction product outlet 3, reacts The product outlet 3 extends to the top of the reactor; the bottom of the reactor body 1 is provided with a grease feeding pipe 4, and the grease feeding pipe 4 extends to the bottom of the reactor, and the bottom of the reactor body 1 is provided with an emptying pipe 5. The inner cavity of the reactor body 1 is provided with a mixed solution heater 6 and several reaction discs a and b, the reaction discs a and reaction discs b are alternately placed in the inner cavity of the reactor body, and the adjacent reaction discs A multi-stage reaction chamber 7 is formed between the plate a and the reaction circular plate b.

[0036] In the present invention, the di...

Embodiment 2

[0043] Taking the transesterification reaction of oil and soybean oil and glycerin as an example, the entire continuous reactor equipment is evacuated through the emptying pipe 5 to prevent the oxidation of the materials entered in the previous stage; The solution enters from the catalyst solution feeding pipe 2 at the top of the continuous reactor, passes through multiple reaction discs a and b to reach the heating zone, and at the same time, the oil and soybean oil entering from the oil feeding pipe 4 reacts while heating up, when the temperature rises to 210 degrees , and then add materials from the top catalyst solution feeding pipe 2 and grease feeding pipe 4 at the same time, so that the two materials fill the entire reactor body 1, and the continuous reaction officially starts from then on;

[0044] Add the glycerol solution of the catalyst sodium hydroxide above 160 degrees continuously from the top of the continuous reactor to the catalyst solution into the pipe 2, and...

Embodiment 3

[0046] Carrying out the transesterification reaction to generate diglyceride with embodiment 2 oleander soybean oil and glycerin is example, as Figure 4 As shown, a mixture of free fatty acids of monoglycerides, diesters, and triesters is obtained, which is stored in the raw material storage tank 11 to wait for purification and refining, and is pumped into the first-stage molecular distillation equipment 12 with a material pump, under the conditions of a vacuum degree of 1500-1600pa and a temperature of 100-105 degrees. Under the conditions of vacuum degree 300-400pa, temperature 170-175 degrees, diglyceride oil is removed Residual glycerol in the oil; then enter the third stage molecular distillation equipment 14, under the conditions of vacuum degree 80-130pa and temperature 190-195 degrees, remove the free fatty acid in the diglyceride oil; then enter the fourth stage molecular distillation equipment 15 , at a vacuum of 5-30pa and a temperature of 210-220 degrees, the mono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com