Polyester-like cotton fabric and preparation method thereof

A technology of polyester imitation cotton and fabric, which is applied in the field of full polyester cotton imitation fabric and its preparation, and achieves the effects of good antistatic performance, compact structure and good sterilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The invention provides a polyester-like cotton-like fabric, which comprises a first weaving layer, a second weaving layer and a third weaving layer which are sequentially stacked. The first weaving layer is formed by interweaving a plurality of first composite fibers, the second weaving layer is formed by interweaving a plurality of second composite fibers, and the third weaving layer is formed by interweaving a plurality of third composite fibers.

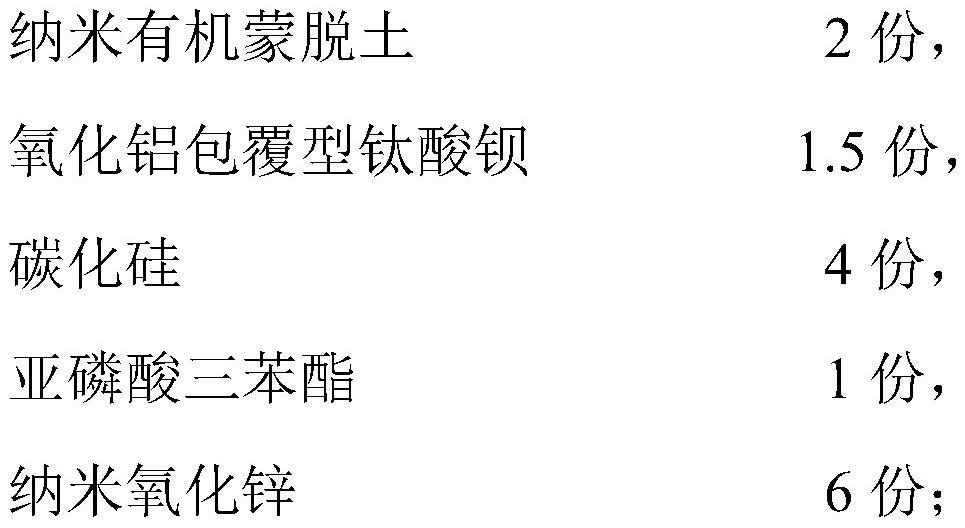

[0044] In the first weaving layer, the first composite fiber is made of the first polyester fiber core and the first additive adsorbed on the first polyester fiber core, and the first additive includes the following raw materials in parts by weight:

[0045]

[0046] Above-mentioned nano organic montmorillonite is phthalimine-montmorillonite;

[0047] In the first composite fiber, the mass ratio of the first polyester fiber core to the first additive is 50:0.75; the cross-section of the first composite fiber is an oblong...

Embodiment 2

[0076] The invention provides a polyester-like cotton-like fabric, which comprises a first weaving layer, a second weaving layer and a third weaving layer which are sequentially stacked. The first weaving layer is formed by interweaving a plurality of first composite fibers, the second weaving layer is formed by interweaving a plurality of second composite fibers, and the third weaving layer is formed by interweaving a plurality of third composite fibers.

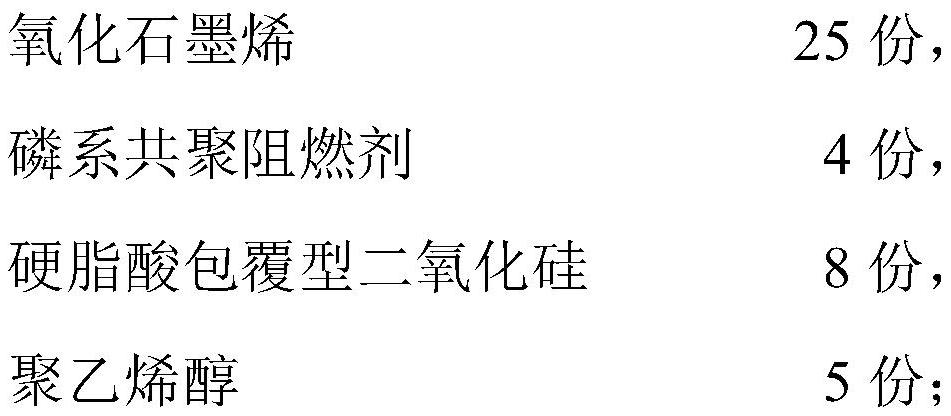

[0077] In the first weaving layer, the first composite fiber is made of the first polyester fiber core and the first additive adsorbed on the first polyester fiber core, and the first additive includes the following raw materials in parts by weight:

[0078]

[0079] The above-mentioned nano-organic montmorillonite is 3,4,5,6-tetrahydrophthalimide-montmorillonite;

[0080] In the first composite fiber, the mass ratio of the first polyester fiber core to the first additive is 100:1; the cross section of the first composit...

Embodiment 3

[0106] The invention provides a polyester-like cotton-like fabric, which comprises a first weaving layer, a second weaving layer and a third weaving layer which are sequentially stacked. The first weaving layer is formed by interweaving a plurality of first composite fibers, the second weaving layer is formed by interweaving a plurality of second composite fibers, and the third weaving layer is formed by interweaving a plurality of third composite fibers.

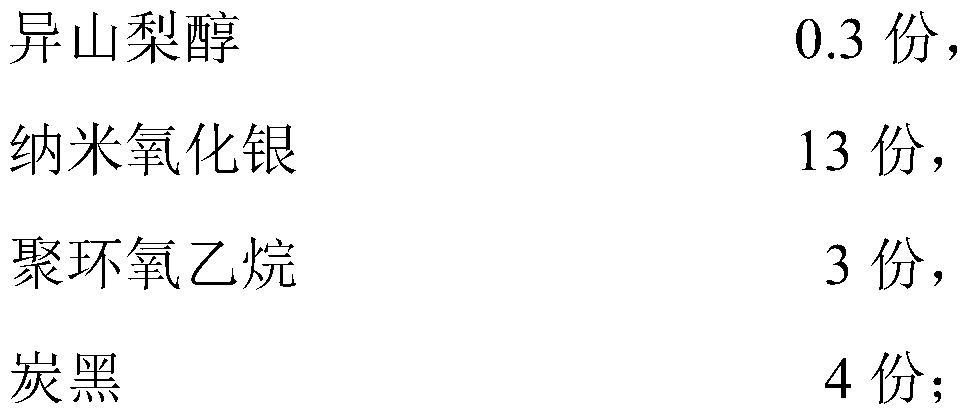

[0107] In the first weaving layer, the first composite fiber is made of the first polyester fiber core and the first additive adsorbed on the first polyester fiber core, and the first additive includes the following raw materials in parts by weight:

[0108]

[0109] The above-mentioned nano-organic montmorillonite is phthalimide-montmorillonite and 3,4,5,6-tetrahydrophthalimide-montmorillonite, and the mass ratio is 1:1;

[0110] In the first composite fiber, the mass ratio of the first polyester fiber core to the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com