A Fresnel zone plate spectral confocal measurement method

A Fresnel zone plate and spectral confocal technology, which is applied in the field of precision measurement, can solve problems such as not using polychromatic light illumination, achieve the effects of flexible design, simplified device structure, and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

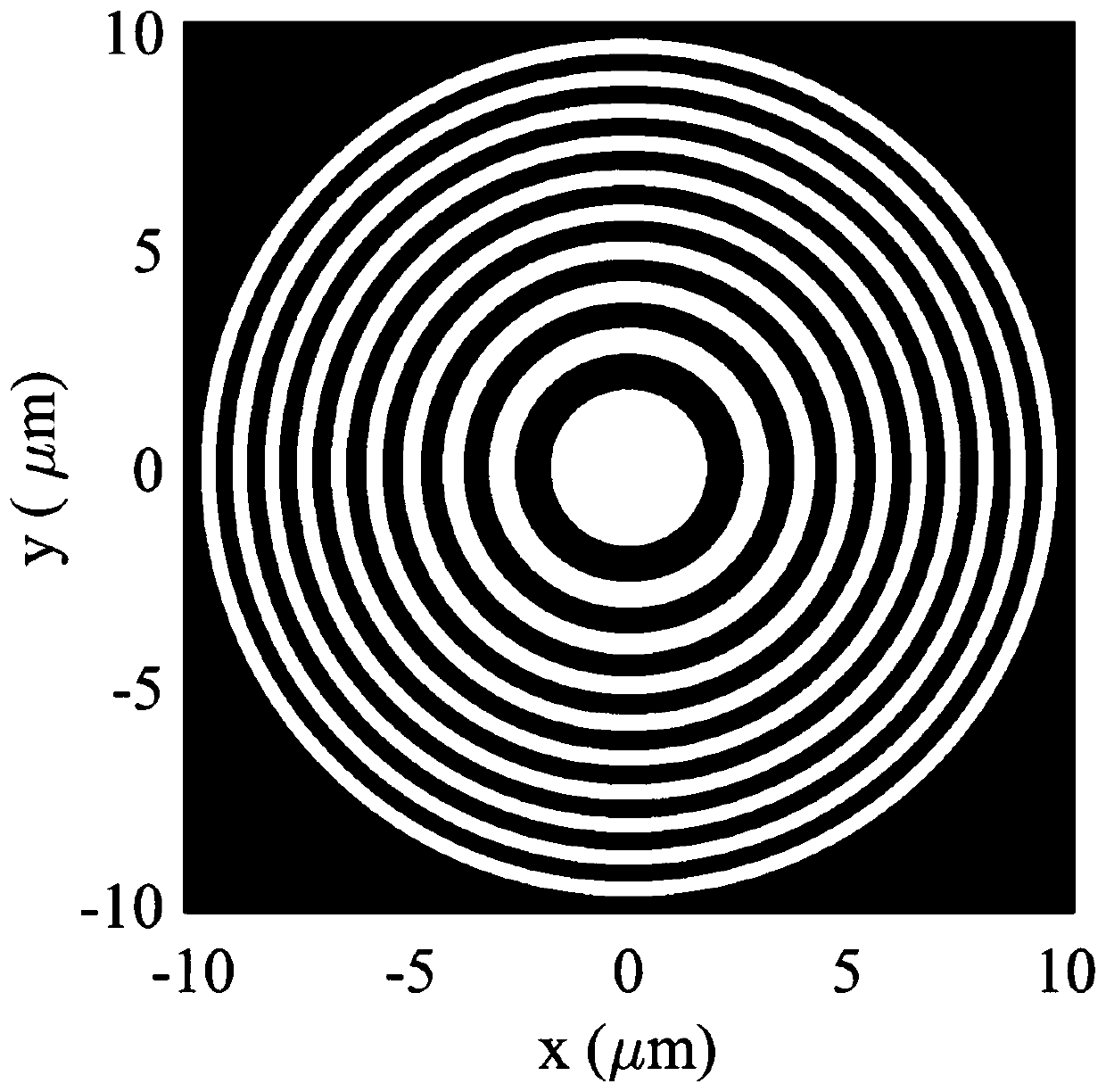

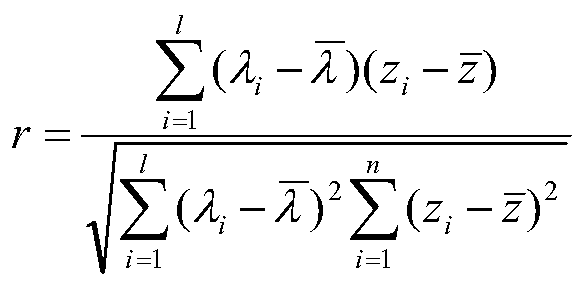

[0048] The invention provides a Fresnel zone plate spectral confocal measurement method, which utilizes the principle of spectral confocal measurement, and produces corresponding to different The color band of the wavelength is different from the traditional spectral confocal measurement method that uses lenses or lens groups for dispersion focusing, which significantly simplifies the structure of the spectral confocal measurement device, and the design is more flexible. Precise measurement of displacement, especially three-dimensional measurement of transparent objects with low reflectivity.

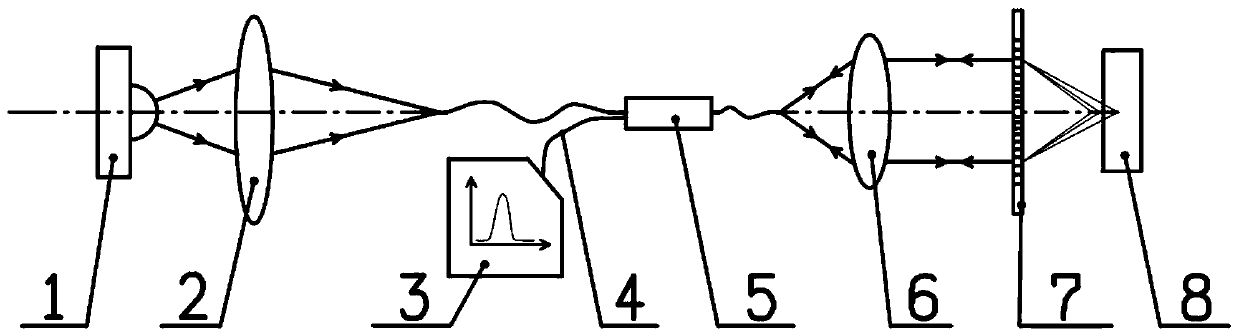

[0049] see figure 1 , a Fresnel zone plate spectrum confocal measurement device of the present invention, comprising a composite light source 1, a lens group 2, a spectrometer 3, an optical fiber 4, a fiber coupler 5, a collimating lens 6, and a Fresnel zone plate 7 , standard flat reflector or sample 8; fiber coupler 5 is arranged between lens group 2 and collimator lens 6, Fresnel zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com