Extraction and quantitative methods for folic acid in corn grains

A technology for grain and corn, applied in the field of plant folic acid extraction, can solve the problems of narrow linear range, inability to distinguish folic acid, and low resolution, and achieve the effects of improving extraction efficiency, helping nutrition-oriented biological breeding, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1. Quantification of folic acid in corn kernels

[0061] 1. Preparation of standard solution

[0062] In addition to 5-F-THFGlu 1 and 13 C 5-F-THFGlu 1 Except, all standards were dissolved in methanol / water (1:1, v / v) containing 20 mM ammonium formate, 1% (w / v) L-ascorbic acid, and 0.5% (v / v) 2-mercaptoethanol middle. 5-F-THFGlu 1 and 13 C 5-F-THFGlu 1 Soluble in an aqueous solution containing 1% (w / v) L-ascorbic acid and 0.5% (v / v) 2-mercaptoethanol. All standard solutions have a concentration of 100 μg / mL and are stored at -80°C for future use. Use the extract to dilute.

[0063] 2. Method for extracting folic acid from corn kernels

[0064] Corn kernel freeze-dried powder : Fresh corn kernels are ground with MM 400 grinder (Retsch, Germany) under liquid nitrogen conditions and freeze-dried in ALPHA 1-4LDPlus freeze dryer (Christ, Germany) to obtain freeze-dried corn kernels, which are packed into 15ml or 50ml freeze-dried powder. Store in a tube at...

Embodiment 2

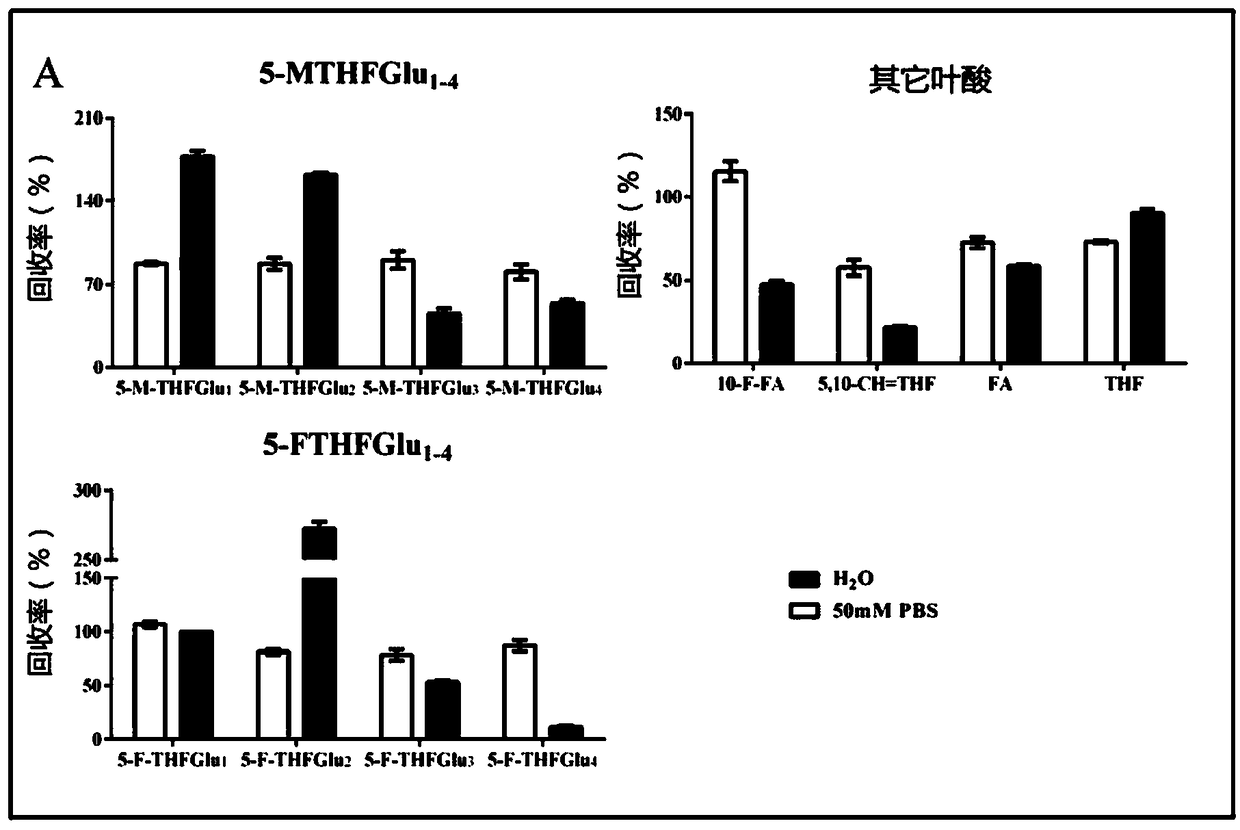

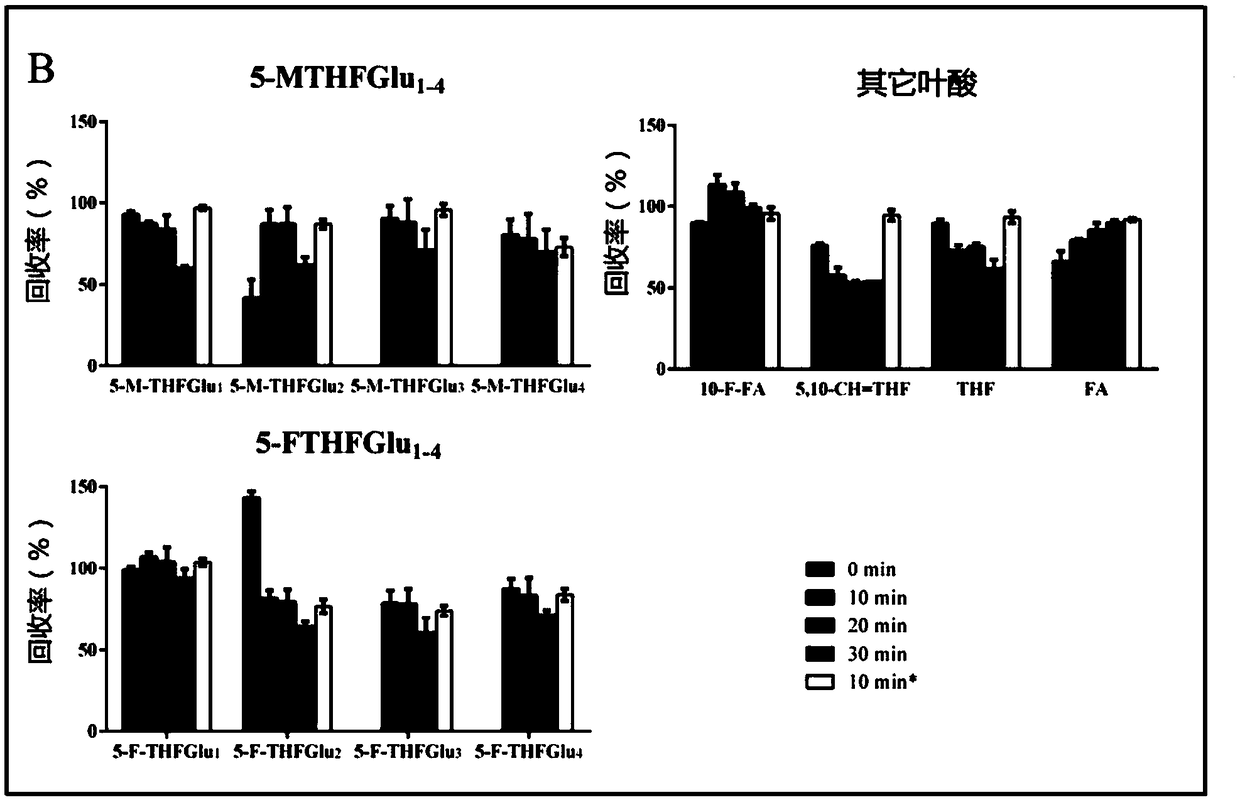

[0103] Embodiment 2. Optimization of folic acid extraction method

[0104] 1. Extraction solvent optimization

[0105] As the main solvent of the whole system, the extraction solution generally uses phosphate buffered saline (PBS) as the solvent. At the same time, mercaptoethanol and ascorbic acid were added as antioxidants. However, since phosphate is not volatile, a large amount of use will affect the ionization efficiency of the mass spectrometer and reduce the service life of the mass spectrometer. Therefore, we compared two extraction solvents, water and PBS, to assess the necessity of using phosphate buffered saline.

[0106] Taking corn kernels of GEMS 31 variety as a sample, the experiment was carried out according to the following method.

[0107] Extraction of folic acid from corn kernels: During extraction, 10-F-FA, THF, FA, 5, 10-CH=THF, 5-M-THFGlu 1-4 and 5-F-THFGlu 1-4 The standard substance is added in the freeze-dried powder of corn kernels with the extrac...

Embodiment 3

[0137] Example 3. Determination of single and polyglutamic acid folic acid content in the corn germination process

[0138] We compared the content changes of monoglutamic acid and polyglutamic acid folic acid in maize germ (GEMS 31) during germination. Embryo materials were collected on days 1-5 of germination, and folic acid in corn germs was extracted and detected by LC-MS / MS according to the method described in Example 1.

[0139] The result is as Figure 4 As shown, 5-M-THFGlu 1-4 , 5-F-THFGlu 1-4 , 5,10-CH=THF, 10-F-FA, FA and THF were detected in all samples. In the first 2 days, the content of folic acid was generally low, and the corn kernels were mainly in the stage of water absorption at this time. After the water absorption stage ended, the total content of 5-M-THF and 5-F-THF increased, and the corresponding distribution of mono- and polyglutamic acid folic acid also changed. 5-M-THFGlu 4 The proportion of the first 4 days remained at about 60%. From day 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com