Geopolymer composite pole and preparation method thereof

A geopolymer and utility pole technology, applied in the field of utility pole preparation, can solve the problems of high cost and high price of ultra-high-performance concrete, and achieve the effects of reducing quality, shortening curing molding cycle, and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method for a geopolymer composite utility pole, comprising the steps of:

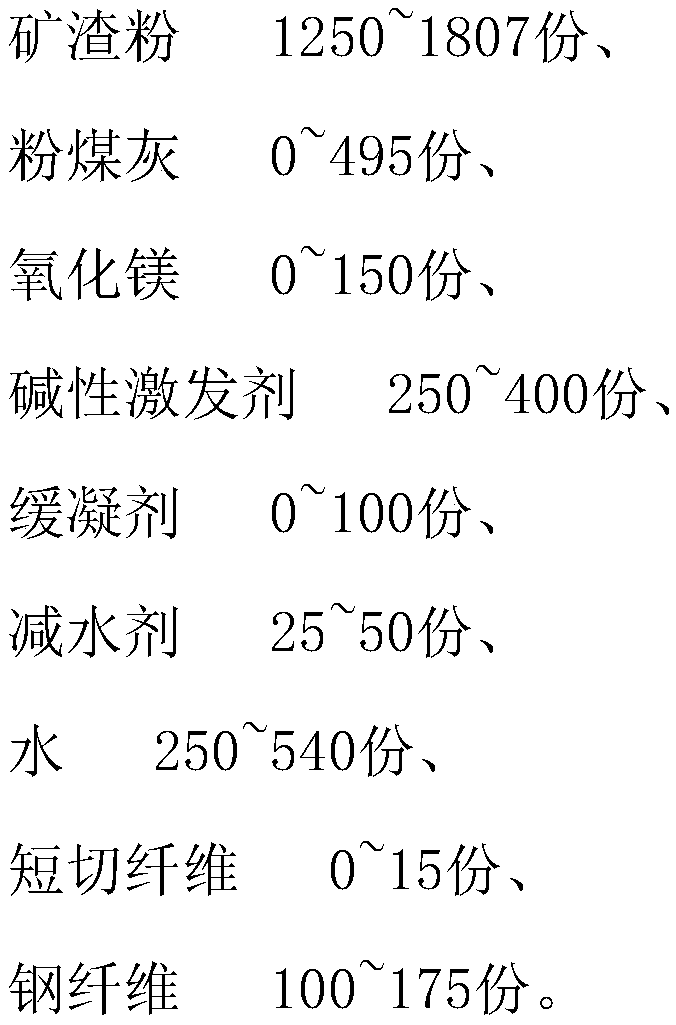

[0039] Wherein, geopolymer is made up of following components, by weight:

[0040] 1300 parts of slag powder,

[0041] 350 parts of fly ash,

[0042] 135 parts of magnesium oxide,

[0043] 358 parts of sodium silicate solution,

[0044] 50 parts of barium nitrate,

[0045] 38 parts of water reducer,

[0046] 355 parts of water,

[0047] Steel fiber 170 parts.

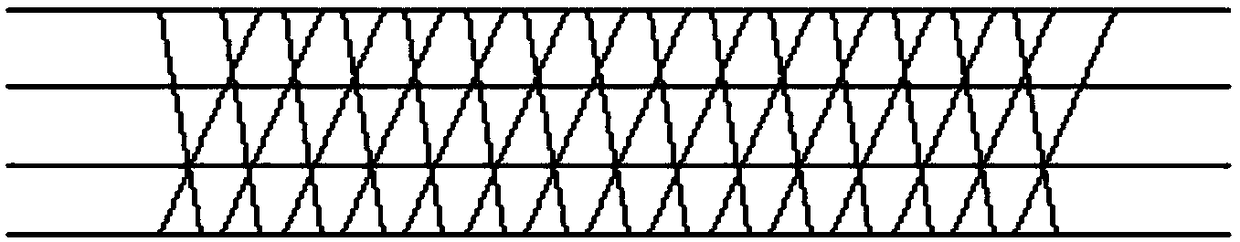

[0048] a. Arrange the glass fiber reinforced ribs with a diameter of 6mm evenly on a set of concentric molds at a distance of 30mm. The fiber yarn is soaked in resin glue and wound evenly along the direction of 45°, and then perpendicular to the first winding Winding again in the direction to form a honeycomb network structure, let it solidify naturally to form a cage-like skeleton that matches the appearance and size of the utility pole;

[0049] b. Put 170 parts of steel fiber, 1300 parts of slag powder, 350 parts o...

Embodiment 2

[0052] A preparation method for a geopolymer composite utility pole, comprising the steps of:

[0053] Wherein, geopolymer is made up of following components, by weight:

[0054] 1300 parts of slag powder,

[0055] 350 parts of fly ash,

[0056] 135 parts of magnesium oxide,

[0057] 358 parts of sodium silicate solution,

[0058] 50 parts of barium nitrate,

[0059] 355 parts of water,

[0060] 38 parts of water reducer,

[0061] Basalt chopped fiber 5 parts,

[0062] Steel fiber 140 parts.

[0063] a. Arrange glass fiber reinforced ribs with a diameter of 6mm evenly on a set of concentric molds at a distance of 30mm. After the fiber yarn is soaked in resin glue, it is evenly wound along the direction of 45°, and then wound perpendicular to the first time Wrap again in the same direction to form a honeycomb network structure, let it solidify naturally to form a cage-like skeleton that matches the appearance and size of the utility pole;

[0064]b. Put 140 parts of st...

Embodiment 3

[0067] A preparation method for a geopolymer composite utility pole, comprising the steps of:

[0068] Wherein, geopolymer is made up of following components, by weight:

[0069] 1807 parts of slag powder,

[0070] 300 parts of sodium silicate solution,

[0071] Calcium hydroxide 35 parts,

[0072] 50 parts of barium chloride,

[0073] 355 parts of water,

[0074] 40 parts of water reducer,

[0075] 15 parts of glass chopped fiber,

[0076] Steel fiber 120 parts.

[0077] a. Arrange glass fiber reinforced ribs with a diameter of 12mm evenly on a set of concentric molds at a distance of 30mm. After the fiber yarn is soaked in resin glue, it is evenly wound along the direction of 45°, and then perpendicular to the first winding Wrap again in the same direction to form a honeycomb network structure, let it solidify naturally to form a cage-like skeleton that matches the appearance and size of the utility pole;

[0078] b. Put 120 parts of steel fiber, 15 parts of glass ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com