Flame-retardant semiconductive sheathing material for coal mine gas tubes, and preparation method and application thereof

A technology for coal mine gas and sheathing materials, applied in the field of coal mines, can solve problems such as mine accidents, fire gas, unsatisfactory effects, etc., achieve excellent mechanical properties, excellent flame retardant properties, and avoid the effects of great decline in mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

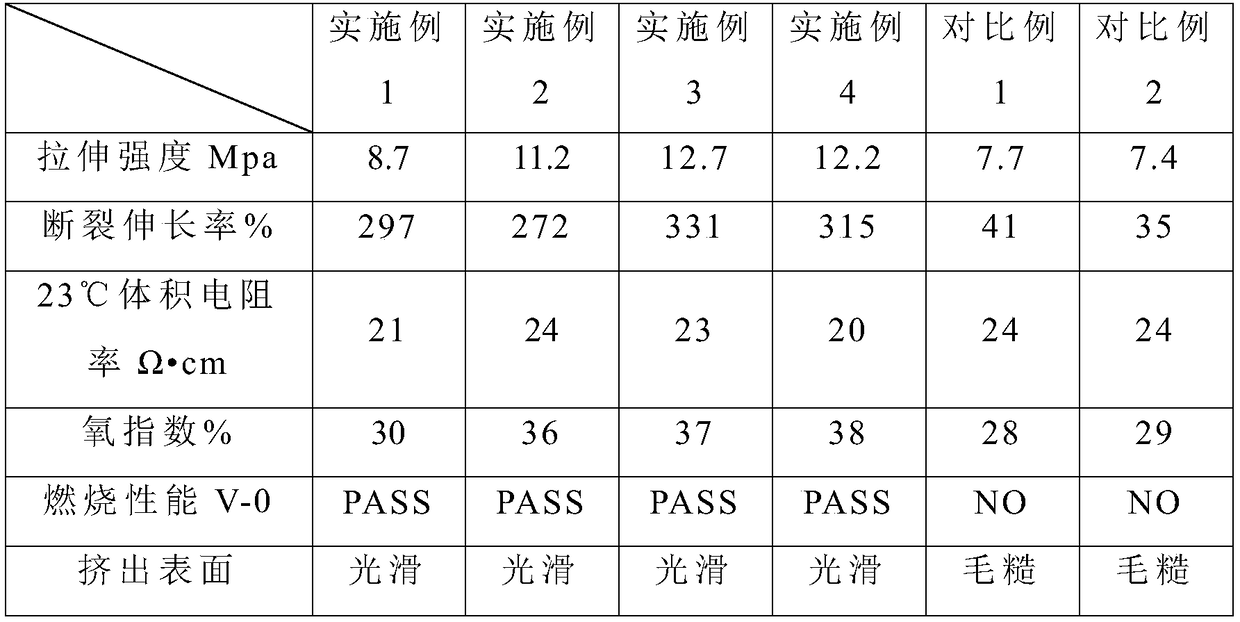

Examples

Embodiment 1

[0031] This embodiment provides a flame-retardant semi-conductive sheath material for coal mine gas pipes. In terms of parts by mass, the raw materials of the sheath material include 5 parts of high-density polyethylene, 70 parts of ethylene-vinyl acetate copolymer, ethylene-octyl 25 parts of vinyl copolymer, 5 parts of pentaerythritol, 20 parts of ammonium polyphosphate, 10 parts of melamine cyanurate, 70 parts of conductive carbon black, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) 2 parts of propionic acid] pentaerythritol ester, 5 parts of polyethylene wax.

[0032]Preparation method: (1) Weigh each raw material according to the formula ratio, mix the high-density polyethylene, the ethylene-vinyl acetate copolymer and the ethylene-octene copolymer into a high-speed mixer and stir for 3 minutes at a low speed to obtain first mix;

[0033] (2) Mix the remaining other raw materials into a high-speed mixer and stir for 3 minutes at a high speed to obtain the second mixture;...

Embodiment 2

[0036] This embodiment provides a flame-retardant semi-conductive sheath material for coal mine gas pipes. In terms of parts by mass, the raw materials of the sheath material include 10 parts of high-density polyethylene, 55 parts of ethylene-vinyl acetate copolymer, ethylene-octyl 35 parts of vinyl copolymer, 5 parts of pentaerythritol, 30 parts of ammonium polyphosphate, 15 parts of melamine cyanurate, 70 parts of conductive carbon black, β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid 2 parts of n-octadecanyl alcohol ester, 5 parts of polyethylene wax.

[0037] The preparation method is the same as in Example 1.

Embodiment 3

[0039] This embodiment provides a flame-retardant semi-conductive sheath material for coal mine gas pipes. In terms of parts by mass, the raw materials of the sheath material include 5 parts of high-density polyethylene, 45 parts of ethylene-vinyl acetate copolymer, ethylene-octyl 50 parts of ethylene copolymer, 5 parts of tripentaerythritol, 30 parts of ammonium polyphosphate, 10 parts of melamine cyanurate, 75 parts of conductive carbon black, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl ) 2 parts of propionic acid] pentaerythritol ester, 5 parts of polyethylene wax.

[0040] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com