Lithium sulfide battery

A battery, sulfur-lithium technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of irreversible loss of active materials, battery capacity attenuation, and poor cycle stability of lithium-sulfur batteries, and achieve enhanced conductivity and reduced Small attenuation, the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

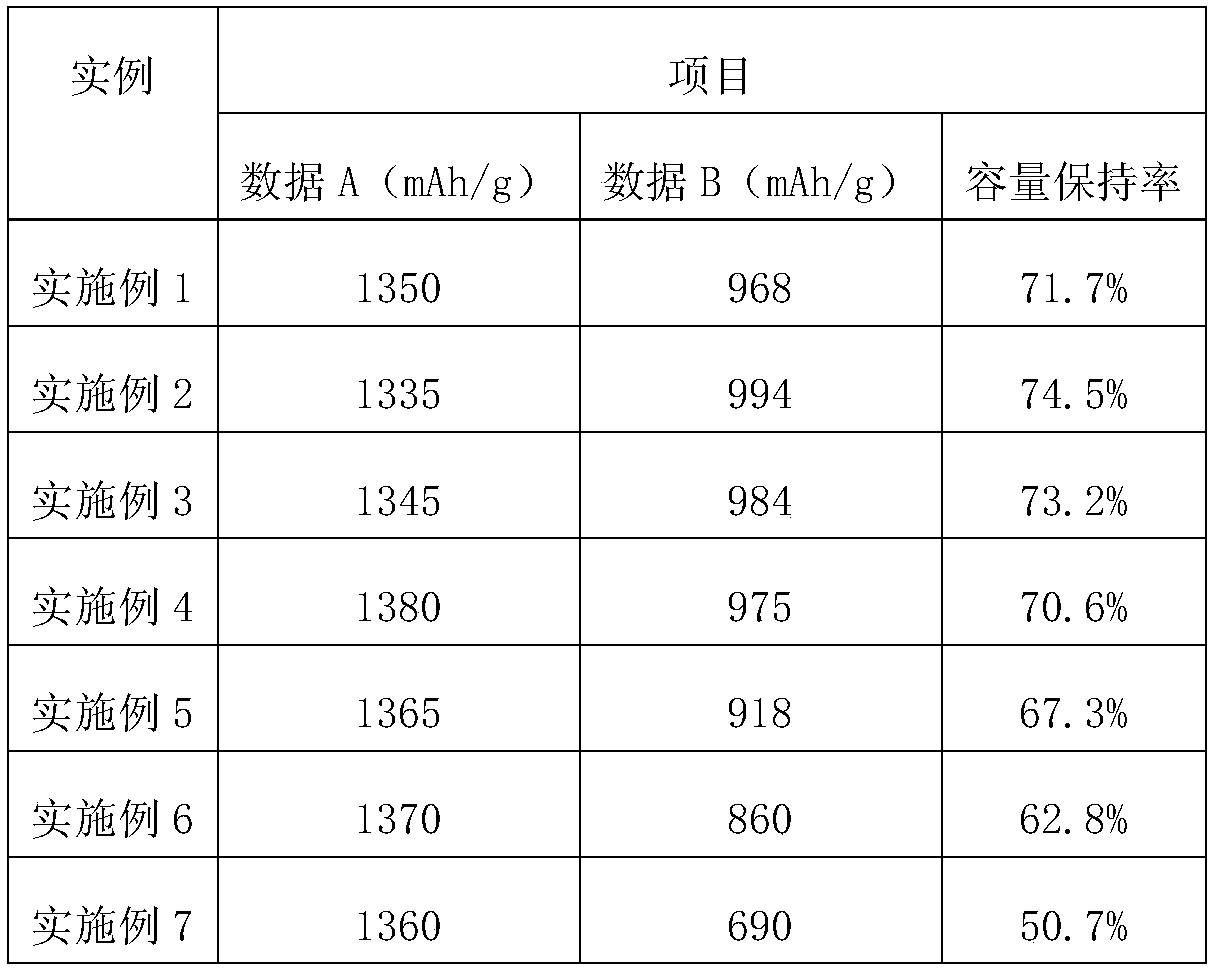

Examples

Embodiment 1

[0023] Graphene oxide prepared by the Hummers method was dissolved in water to prepare a 10 mg / L graphene oxide aqueous solution, and silicon dioxide with a particle size of 200 nm was ultrasonically dispersed (50 kHz ultrasonic dispersion treatment for 1 h) into deionized water to obtain a 50 mg / L Silica dispersion, mix the graphene oxide aqueous solution and the silica dispersion according to the volume ratio of 1:5, 50kHz ultrasonic dispersion treatment for 2h to obtain the mixed solution A, and place the barrel containing the mixed solution A on a constant temperature magnetic stirrer , Stir the mixed liquid A at a constant temperature of 50°C, insert the feed pipe of the spray dryer (LPG-5) into the barrel, start the spray dryer, and adjust the air intake to 5m 3 / min, the inlet temperature is 200°C, the feed rate of the mixed solution A is 5mL / min, the needle passing rate is 1 time / 10s, and the material A (graphene-coated silica material) is obtained by spray drying. A i...

Embodiment 2

[0029] Graphene oxide prepared by the Hummers method was dissolved in water to prepare a 10mg / L graphene oxide aqueous solution, and silicon dioxide with a particle size of 200nm was ultrasonically dispersed (50kHz ultrasonic dispersion treatment for 1h) into absolute ethanol to obtain a 50mg / L Silica dispersion liquid, the graphene oxide aqueous solution and the silica dispersion liquid are mixed according to the volume ratio of 1:5, 50kHz ultrasonic dispersion treatment for 2h to obtain the mixed liquid A, and the barrel containing the mixed liquid A is placed in a constant temperature magnetic stirrer Stir the mixed solution A at a constant temperature of 50°C, insert the feed pipe of the spray dryer (LPG-5) into the barrel, start the spray dryer, and adjust the air intake to 5m 3 / min, the inlet temperature is 220°C, the feed rate of the mixed solution A is 5mL / min, the needle passing rate is 1 time / 10s, and the material A (graphene-coated silica material) is obtained by sp...

Embodiment 3

[0035]Graphene oxide prepared by the Hummers method was dissolved in water to prepare a 10mg / L graphene oxide aqueous solution, and silicon dioxide with a particle size of 200nm was ultrasonically dispersed (50kHz ultrasonic dispersion treatment for 1h) into ethylene glycol to obtain a 50mg / L Silica dispersion liquid, the graphene oxide aqueous solution and the silica dispersion liquid are mixed according to the volume ratio of 1:5, 50kHz ultrasonic dispersion treatment for 2h to obtain the mixed liquid A, and the barrel containing the mixed liquid A is placed in a constant temperature magnetic stirrer Stir the mixed solution A at a constant temperature of 50°C, insert the feed pipe of the spray dryer (LPG-5) into the barrel, start the spray dryer, and adjust the air intake to 5m 3 / min, the inlet temperature is 230°C, the feed rate of the mixed solution A is 5mL / min, the needle passing rate is 1 time / 10s, and the material A (graphene-coated silica material) is obtained by spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com