Preparation process of hematodialysis concentrate A powder

A technology of hemodialysis and preparation process, applied in the field of hemodialysis, can solve the problems of unstable product quality of hemodialysis concentrate A powder, increase in transportation and storage costs, and increase in dissolution time, and achieve easy preparation and storage, and reduce product differences. Small, stable product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A hemodialysis concentrate A powder, comprising the following components by weight: 16000 g of anhydrous sodium chloride, 500 g of anhydrous potassium chloride, 600 g of calcium chloride dihydrate, 300 g of magnesium chloride hexahydrate and 600 g of anhydrous citric acid.

[0039] A preparation process of hemodialysis concentrate A powder, the operation process is completed in the operation room, and the temperature of the operation room is adjusted to 15°C, relative humidity ≤ 40%, and planktonic bacteria ≤ 100 / m 3 , sedimentation bacteria ≤ 3 / petri dish, and the pressure difference between adjacent operations ≥ 10Pa, specifically include the following steps:

[0040] (1) Take each raw material according to the above-mentioned a kind of hemodialysis concentrate A powder, and set aside;

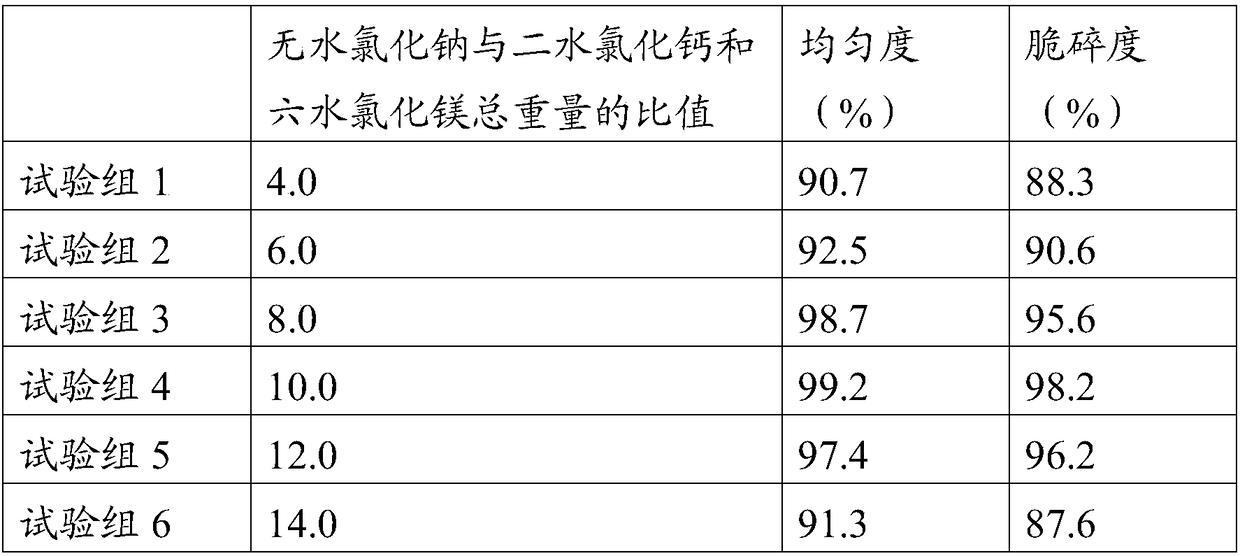

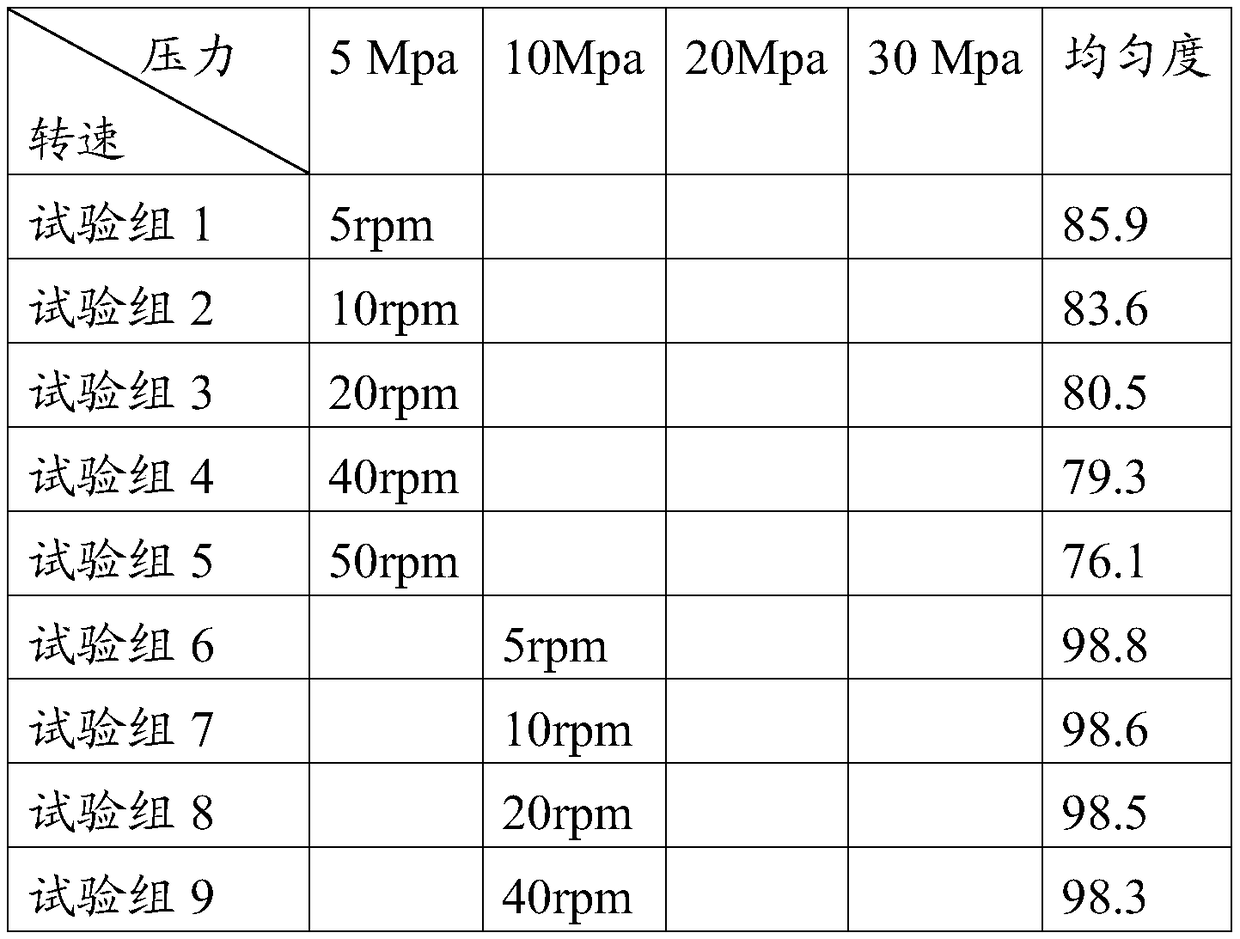

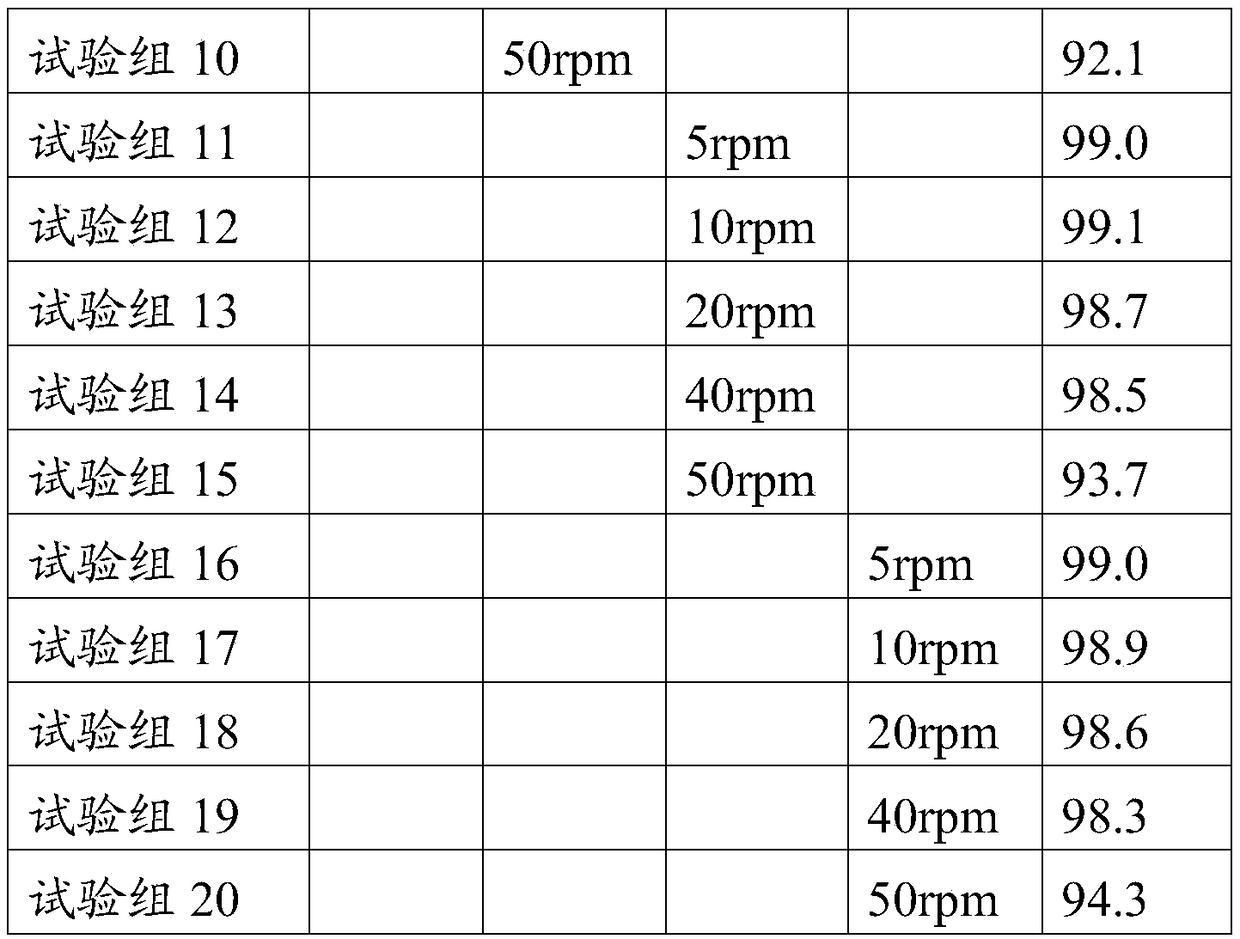

[0041](2) Add calcium chloride and magnesium chloride to the mixing tank of the three-dimensional mixer through the feeding port after sieving, and then add anhydrous sodium chloride ...

Embodiment 2

[0047] A hemodialysis concentrate A powder, comprising the following components by weight: 22000g of anhydrous sodium chloride, 800g of anhydrous potassium chloride, 900g of calcium chloride dihydrate, 400g of magnesium chloride hexahydrate, 1000g of anhydrous citric acid and anhydrous Water glucose 7000g.

[0048] A preparation process of hemodialysis concentrate A powder, the operation process is completed in the operation room, the temperature of the operation room is adjusted to 30°C, the relative humidity is ≤40%, and the planktonic bacteria is ≤100 / m 3 , sedimentation bacteria ≤ 3 / petri dish, and the pressure difference between adjacent operations ≥ 10Pa, specifically include the following steps:

[0049] (1) Take each raw material according to the above-mentioned a kind of hemodialysis concentrate A powder, and set aside;

[0050] (2) Add calcium chloride and magnesium chloride to the mixing tank of the three-dimensional mixer through the feeding port after sieving, an...

Embodiment 3

[0056] A hemodialysis concentrate A powder, comprising the following components by weight: 21070g of anhydrous sodium chloride, 522g of anhydrous potassium chloride, 643g of calcium chloride dihydrate, 356g of magnesium chloride hexahydrate, 739g of anhydrous citric acid and anhydrous Water glucose 2000g.

[0057] A preparation process of hemodialysis concentrate A powder, the operation process is completed in the operation room, and the temperature of the operation room is adjusted to 20°C, relative humidity ≤ 40%, and planktonic bacteria ≤ 100 / m 3 , sedimentation bacteria ≤ 3 / petri dish, and the pressure difference between adjacent operations ≥ 10Pa, specifically include the following steps:

[0058] (1) Take each raw material according to the above-mentioned a kind of hemodialysis concentrate A powder, and set aside;

[0059] (2) Add calcium chloride and magnesium chloride to the mixing tank of the three-dimensional mixer through the feed port after sieving, and then add a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com