Fluorine-containing polyaspartic acid ester resin and synthesis method thereof

A technology of aspartic acid ester and synthesis method, which is applied in the field of fluorine-containing polyaspartic acid ester resin and its synthesis, can solve problems such as inferiority and lowering of paint film hardness, and achieve enhanced hydrophobicity, reduced surface tension, and improved The effect of protecting the role of the main chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

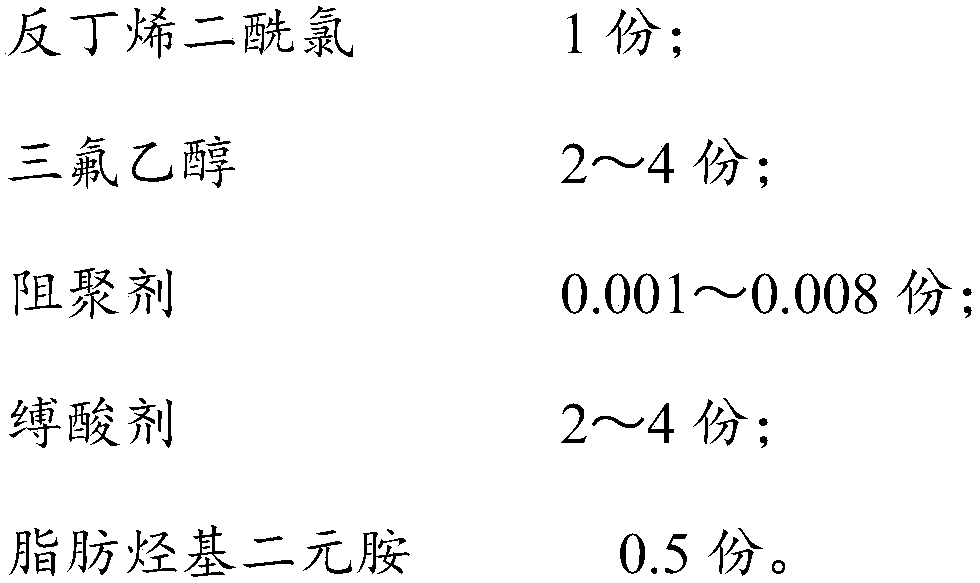

[0034] A kind of fluorine-containing polyaspartate resin, the resin raw material required for its synthesis comprises the following components:

[0035]

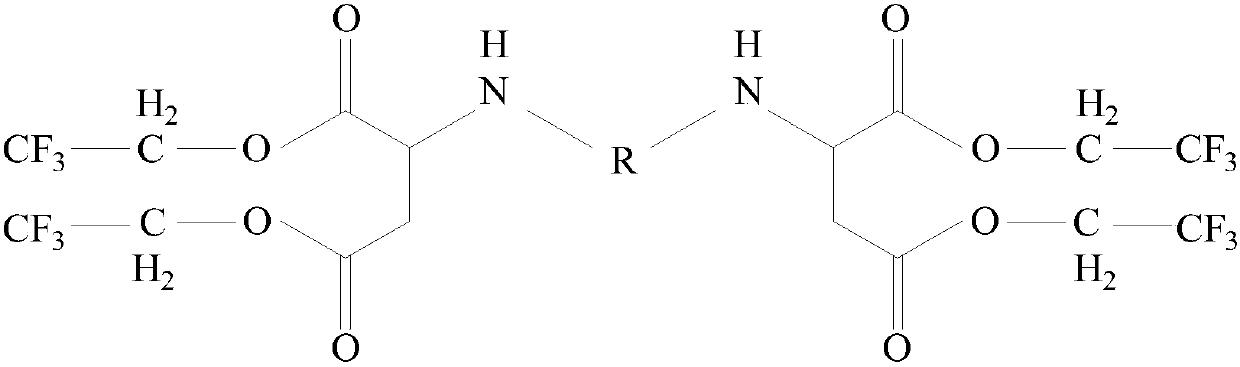

[0036] Fumaryl chloride, trifluoroethanol, p-hydroxyphenyl ether, and pyridine were mixed in a 1000ml four-necked flask and heated to 70°C for 3 hours. The product is washed with water to remove salt, and finally purified by rectification to obtain fumaric acid-1,1'-di(2,2,2-trifluoroethyl) ester. Get 353g fumaric acid-1,1'-bis(2,2,2-trifluoroethyl) ester and 110g of 4,4'-diaminodicyclohexylmethane and mix in a 500ml four-necked flask, Heat preservation at 80° C. for 48 hours to obtain a fluorine-containing modified aspartic acid ester resin product with a molecular weight of 772. Its main reaction formula is:

[0037]

Embodiment 2

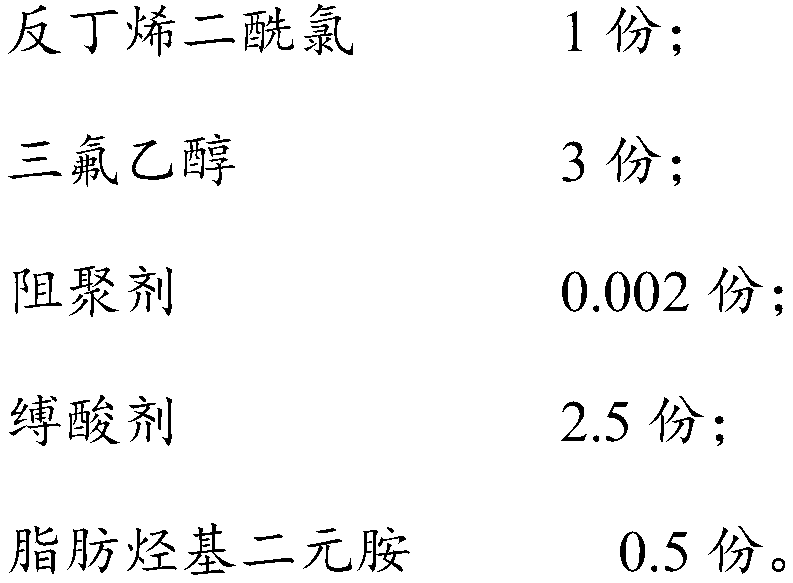

[0039] A kind of fluorine-containing polyaspartic acid ester resin, the synthetic component of described fluorine-containing polyaspartic acid ester resin is as follows:

[0040]

[0041] Fumaryl chloride, trifluoroethanol, p-hydroxyphenyl ether, and pyridine were mixed in a 1000ml four-neck flask and heated to 60°C for 3 hours. The product is washed with water to remove salt, and finally purified by rectification to obtain fumaric acid-1,1'-di(2,2,2-trifluoroethyl) ester. Take 353g of fumaric acid-1,1'-di(2,2,2-trifluoroethyl) ester with 4,4'-diaminodicyclohexylmethane and 3,3'-dimethyl-4 , 4'-diaminodicyclohexylmethane was mixed in a 500ml four-necked flask, and kept at 70°C for 60 hours to obtain a fluorine-containing modified aspartate product with a molecular weight of 791.

Embodiment 3

[0043] A kind of fluorine-containing polyaspartic acid ester resin, the synthetic component of described fluorine-containing polyaspartic acid ester resin is as follows:

[0044]

[0045] Fumaryl chloride, trifluoroethanol, p-hydroxyphenyl ether, and triethylamine were mixed in a 1000ml four-neck flask and heated to 50°C for 4 hours. The product is washed with water to remove salt, and finally purified by rectification to obtain fumaric acid-1,1'-di(2,2,2-trifluoroethyl) ester. Get 353g of fumaric acid-1,1'-bis(2,2,2-trifluoroethyl) ester and isophorone diamine and mix them in a 500ml four-necked flask, and incubate at 90°C for 30 hours to obtain the molecular weight It is 732 fluorine-containing modified aspartate product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com