Directionally arranged graphene film, preparation method thereof and composite heat dissipating film

A graphene film, directional arrangement technology, applied in chemical instruments and methods, synthetic resin layered products, lamination and other directions, can solve problems such as poor mechanical properties, high equipment requirements, difficult to restore, etc., and achieve good bending resistance. excellent heat dissipation performance, and the effect of reducing contact thermal resistance

Active Publication Date: 2018-12-28

SHENZHEN SELEN SCI & TECH CO LTD

View PDF11 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, Chinese patent 201410146002.1 discloses a method for directional preparation of graphene film with high electrical conductivity and high thermal conductivity by liquid phase method, that is, graphene oxide film is prepared by vacuum temperature control and vacuum filtration to prepare directional deposited graphene oxide film, and then reduced by chemical vapor deposition. , to obtain a directional deposited graphene film, the method is complicated in steps and requires high equipment, and the prepared graphene film is deposited on copper foil or other substrates, which is difficult to transfer, and the graphene film is easily damaged during transfer, and at the same time In this method, graphene oxide prepared by the hummer method is used as a precursor, and the graphene film is obtained through reduction treatment. It is difficult to achieve complete reduction, resulting in some defects in graphene, which makes it difficult to fully reflect the intrinsic high thermal conductivity of graphene, and obtains The highest thermal conductivity of graphene film is only 800W / (m K), which is still far from its theoretical thermal conductivity.

Chinese patent 201410331358.2 discloses a preparation method of nitrogen-doped oriented graphene, that is, adding ammonia water to graphene oxide solution, performing hydrothermal reaction, reducing graphene oxide to graphene, and then performing directional vacuum treatment. The obtained graphene film is just a simple powder overlapping film, which is easy to drop powder, has poor mechanical properties, is easy to bend and break, is difficult to process, and is difficult to transfer directly from the filter paper. In order to reduce the damage to the film layer during the transfer process, The thickness of the graphene film will be increased to the millimeter level, which cannot meet the requirements of thinning and thinning in the field of electronic equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0043] The present invention will be further described below in conjunction with embodiment, but following embodiment is only preferred embodiment of the present invention, so can not limit the scope of the present invention implementation accordingly, namely the equivalence done according to the patent scope of the present invention and description content Changes and modifications should still fall within the scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

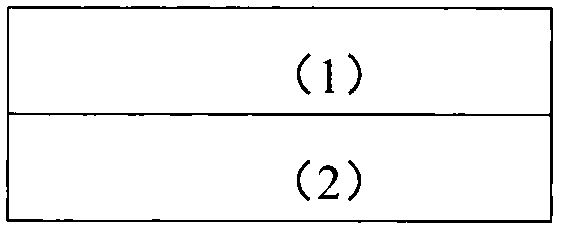

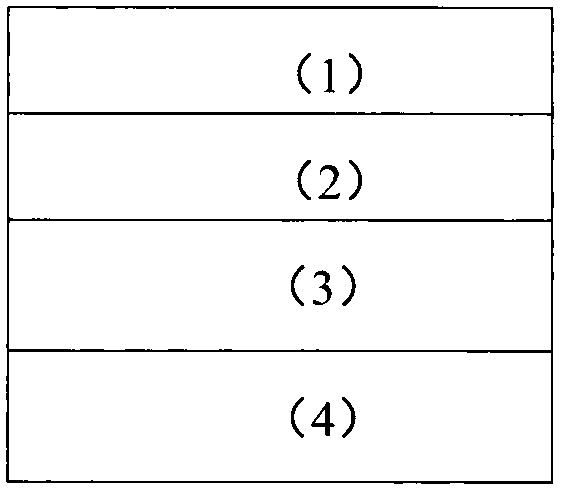

The invention provides a graphene film. The graphene film comprises the following components by mass: 100 parts of modified graphene, 250-450 parts of solvent, 15-0 parts of film former, 0.5-1.5 partsof curing agent, 0.25-15 parts of modifier and 3-10 parts of auxiliary agent. The thickness of the graphene film is 10-80 Mum. The graphene film is directionally arranged and large in heat dissipating area, has high thermal conductivity, thermal emissivity and good flexibility, bending resistance, impact resistance and processability and is not prone to powder drop. A composite heat dissipating film is further provided. The composite heat dissipating film sequentially comprises ultra-thin thermal conductive silica gel pad and the directionally arranged graphene film from bottom to top. The composite heat dissipating film can directly contact a heat source without double-sided adhesive. The contact thermal resistance is greatly reduced. The composite heat dissipating film has good thermalconductivity and mechanical properties, and can be widely used in the field of heat dissipation of electronic products.

Description

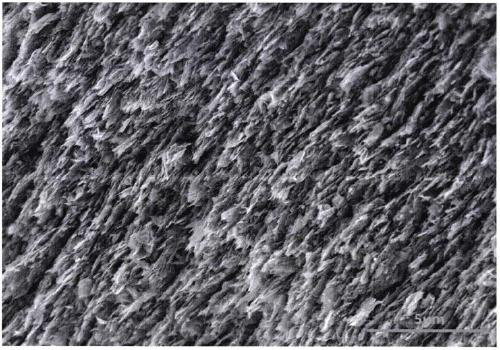

technical field [0001] The invention relates to the field of heat dissipation films, in particular to a graphene film and a composite heat dissipation film. Background technique [0002] In recent years, with the continuous improvement of the performance of industrial and consumer electronic products, the heating problem of various electronic devices has become more and more serious, and heat dissipation is particularly important. The theoretical thermal conductivity of graphene is 3000-5000W / (m·K), which can be applied in the field of heat dissipation of electronic products. However, in practical applications, large interlayer gaps will be generated after the graphene sheets are assembled into a film. The gaps not only form thermal resistance, but also affect the density of the graphene film, thereby reducing the overall heat transfer efficiency of the graphene heat-conducting film. Therefore, in order to obtain a graphene film with high thermal conductivity, it is necessa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L75/14C08L33/00C08L39/06C08L29/04C08L25/18C08K13/06C08K9/04C08K7/00C08K7/24C08K3/04C08J5/18B32B27/36B32B9/00B32B9/04B32B33/00B32B37/10B32B38/00

CPCB32B9/00B32B9/045B32B27/36B32B33/00B32B37/10B32B38/00B32B2038/0076B32B2255/26B32B2307/206B32B2307/302B32B2307/54B32B2307/558C08J5/18C08J2333/00C08J2375/14C08J2425/18C08J2429/04C08J2439/06C08K3/04C08K7/00C08K7/24C08K9/08C08K13/06C08K2201/011C08K3/041

Inventor 林菊香邝许平矦亚茹陈斌郭辉

Owner SHENZHEN SELEN SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com