Method for modifying bamboo powder with maleic anhydride and maleic acid grafted polyethylene wax and application

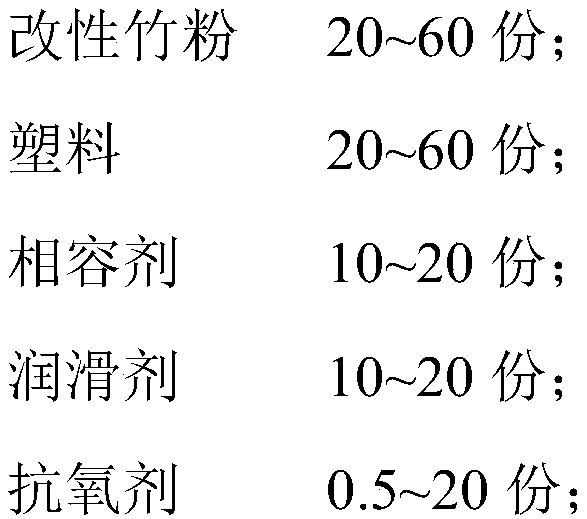

A technology of grafting polyethylene and maleic anhydride, which is applied in the field of bamboo powder processing, can solve the problems of not being able to improve the comprehensive mechanical properties of hygroscopicity, modification, etc., and achieve a technology that is suitable for large-scale production, improves bonding strength, and is simple and feasible. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

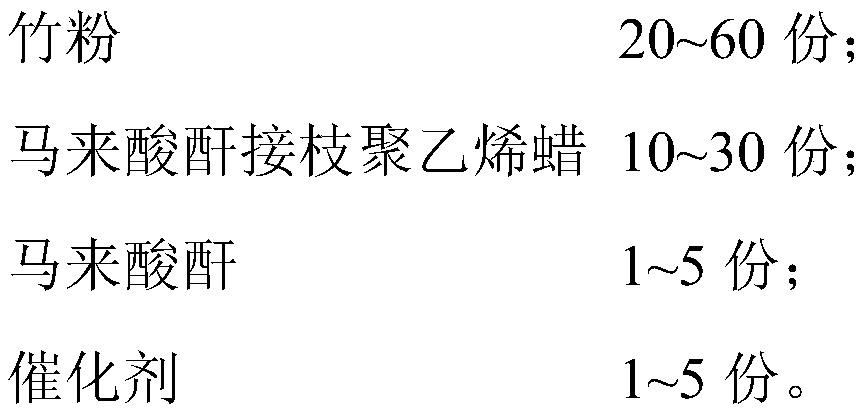

[0054] A method for modifying bamboo powder and maleic anhydride and maleic anhydride grafted polyethylene wax modified bamboo powder, wherein the raw material of modified bamboo powder is the following raw materials in parts by weight:

[0055] 60 parts of moso bamboo powder, passed through a 100-mesh sieve;

[0056] 30 parts of maleic anhydride grafted polyethylene waxes, the weight-average molecular weight is 1500;

[0057] 8.5 parts of maleic anhydride;

[0058] Zinc stearate 1.5 parts.

[0059] The modification method of described bamboo powder is as follows:

[0060] Put the moso bamboo powder, maleic anhydride grafted polyethylene wax, maleic anhydride and zinc stearate described in Example 1 in a high mixer, heat to 110°C, and stir for 4 minutes at a speed of 750r / min , then stirred at a speed of 1750r / min for 15min, and then cooled to below 40°C to obtain modified bamboo powder.

Embodiment 2

[0062] A method for modifying bamboo powder and maleic anhydride and maleic anhydride grafted polyethylene wax modified bamboo powder, wherein the raw material of modified bamboo powder is the following raw materials in parts by weight:

[0063] 60 parts of moso bamboo powder, passed through a 200-mesh sieve;

[0064] 30 parts of maleic anhydride grafted polyethylene waxes, the weight-average molecular weight is 3000;

[0065] 8.5 parts of maleic anhydride;

[0066] 1.5 parts of magnesium stearate.

[0067] The modification method of described bamboo powder is as follows:

[0068] Put the moso bamboo powder, maleic anhydride grafted polyethylene wax, maleic anhydride and magnesium stearate described in Example 2 in a high mixer, heat to 110°C, and stir for 4 minutes at a speed of 750r / min , then stirred at a speed of 1750r / min for 15min, and then cooled to below 40°C to obtain modified bamboo powder.

Embodiment 3

[0070] A method for modifying bamboo powder and maleic anhydride and maleic anhydride grafted polyethylene wax modified bamboo powder, wherein the raw material of modified bamboo powder is the following raw materials in parts by weight:

[0071] 60 parts of moso bamboo powder, passed through a 300-mesh sieve;

[0072] 30 parts of maleic anhydride grafted polyethylene waxes, the weight-average molecular weight is 5000;

[0073] 8.5 parts of maleic anhydride;

[0074] Rare earth catalyst 1.5 parts.

[0075] The modification method of described bamboo powder is as follows:

[0076] Put the moso bamboo powder, maleic anhydride grafted polyethylene wax, maleic anhydride and rare earth catalyst described in Example 3 in a high mixer, heat to 110°C, first stir for 4min at a speed of 750r / min with a rotating speed, and then The modified bamboo powder can be obtained by stirring at a speed of 1750r / min for 15min, and then cooling to below 40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com