New method for preparing lung protein powder from animal lung

A technology of protein powder and a new method, which is applied in animal protein processing, protein food processing, protein food ingredients, etc., can solve the problems of waste of biological resources, waste of waste, environmental pollution, etc., and achieve short production cycle, no waste, and extensive The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

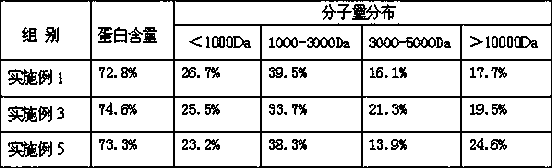

Examples

Embodiment 1

[0018] (1) Chopping and mixing: take 100 kg of fresh pig lungs, wash and decontaminate them, and grind them into minced meat with a chopping machine to obtain minced lungs;

[0019] (2) Cooking: add 300 kg of water to the lung minced material, stir and mix well, adjust the pH value to 8.5 with NaOH solution, raise the temperature to 98°C, keep warm and cook for 1.5 hours, filter off the oil floating on the upper layer, and get cooking liquid;

[0020] (3) Homogenization: Grind and homogenize the cooking liquid through a homogenizer for 10 minutes while it is hot to obtain lung homogenate;

[0021] (4) Enzymolysis: adjust the pH value of the lung homogenate to 8.2, add 5.0 grams of alkaline protease per kilogram of fresh lung, heat to 53°C, and keep warm for 2 hours to obtain the enzymolysis solution;

[0022] (5) Spray drying: spray-dry the obtained enzymatic hydrolysis solution to obtain 17.3Kg of lung protein powder.

Embodiment 2

[0024] (1) Cutting and mixing: take 100 kg of frozen pig lungs, wash and decontaminate them after thawing, and grind them into minced meat with a chopping machine to obtain minced lungs;

[0025] (2) Cooking: Add 400 kg of water to the lung minced material, stir and mix well, adjust the pH value to 9.0 with NaOH solution, raise the temperature to 95°C, keep warm and cook for 2 hours, filter off the oil floating on the upper layer, and get cooking liquid;

[0026] (3) Homogenization: Grind and homogenize the cooking liquid through a homogenizer for 5 minutes while it is hot to obtain a lung homogenate;

[0027] (4) Enzymolysis: Adjust the pH value of the lung homogenate to 8.8, add 3.5 grams of alkaline protease per kilogram of fresh lung, heat to 52°C, and keep warm for 1.5 hours to obtain the enzymolysis solution;

[0028] (5) Spray drying: spray-dry the obtained enzymatic hydrolysis solution to obtain 15.6 kg of lung protein powder.

Embodiment 3

[0030] (1) Chop and mix: take 100 kg of fresh sheep lungs, wash and decontaminate, and grind them into minced meat with a chopping machine to obtain minced lung;

[0031] (2) Cooking: Add 350 kg of water to the lung minced material, stir and mix well, adjust the pH value to 8.8 with NaOH solution, raise the temperature to 98°C, keep warm and cook for 1 hour, filter off the oil floating on the upper layer, and get cooking liquid;

[0032] (3) Homogenization: Grind and homogenize the cooking liquid through a homogenizer for 6 minutes while it is hot to obtain lung homogenate;

[0033] (4) Enzymolysis: Adjust the pH value of the lung homogenate to 8.6, add 5 grams of alkaline protease per kilogram of fresh lung, heat to 55°C, and keep it warm for 1 hour to obtain the enzymolysis solution;

[0034] (5) Spray drying: spray-dry the obtained enzymatic hydrolysis solution to obtain 20.2Kg of lung protein powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com