Method for Improving Cd Adsorption and Fixation Capacity of Corn Stalk Biochar through Abdominal Transformation

A corn stalk, adsorption and fixation technology, applied in the field of agricultural waste recycling and soil heavy metal passivation restoration, can solve the problems of large energy consumption, high moisture content, large biomass of straw, etc., to reduce biomass and energy consumption , Improve the effect of adsorption and fixation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Transabdominal transformation of corn stalks: Take fresh corn stalks, cut them into 2-3cm uniform pieces, mix them with 0.1% salt, and feed them to cattle as the only feed for more than 4 days.

[0024] (2) Cow dung collection and treatment: start to collect cow dung from the second day of feeding, and collect continuously for more than 3 days. The collected cow dung is air-dried at room temperature, and the water content is controlled at 15-20%.

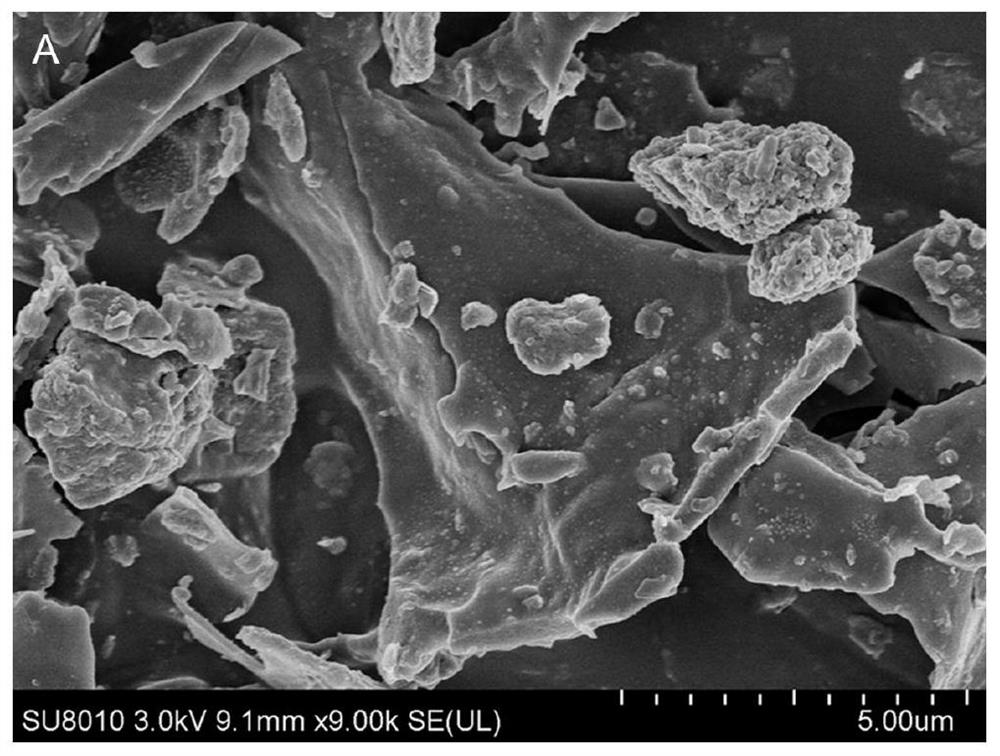

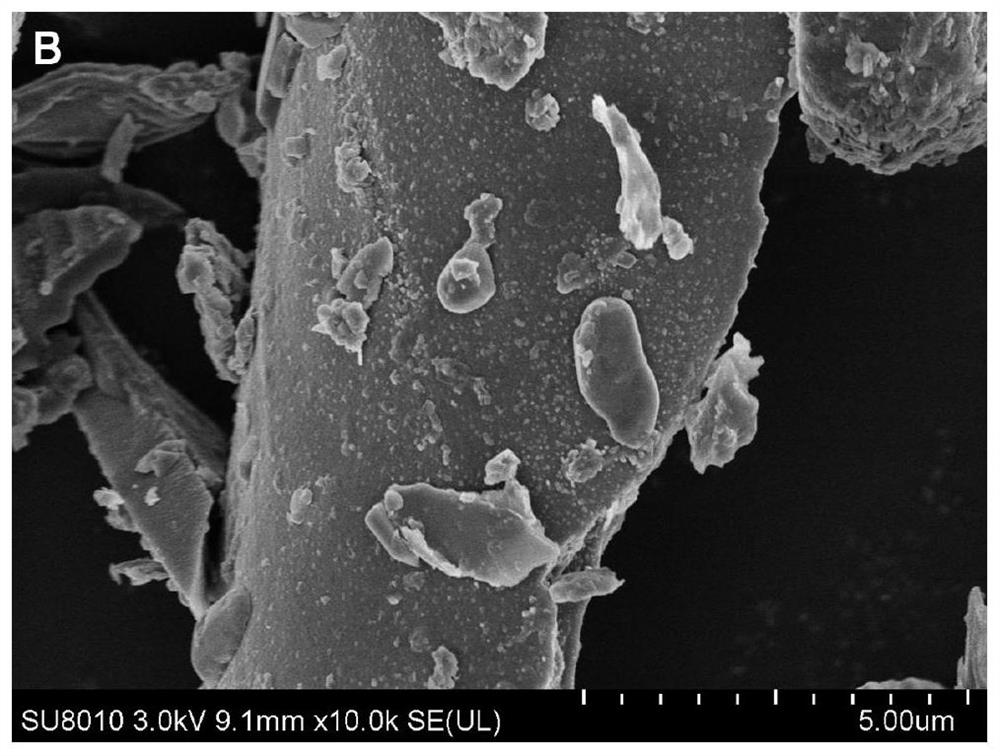

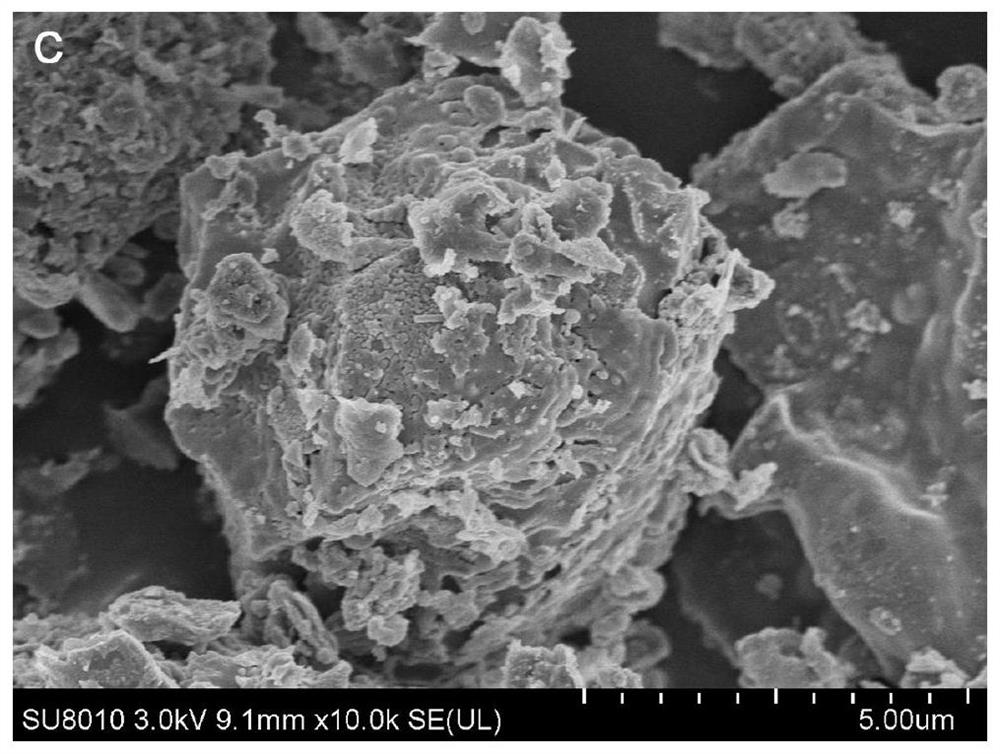

[0025] (3) Preparation of biochar: put the above-mentioned dried cow dung into a crucible, put it into an oven, bake at 65-70°C for 22-24 hours, and control the water content at 4-8%. Then the dried cow dung was put into the muffle furnace, and biochar was prepared by one-step slow pyrolysis. The pyrolysis condition is to raise the temperature to 600°C or 700°C at 20°C / min in a nitrogen atmosphere, and then cool down to room temperature naturally after 3 hours of pyrolysis. Take out the product, grind it through a 40-mes...

Embodiment 2

[0031] (1) Transabdominal transformation of corn stalks: Take fresh corn stalks, cut them into 2-3cm uniform pieces, mix them with 0.1% salt, and feed them to cattle as the only feed for more than 4 days.

[0032] (2) Cow dung collection and treatment: start to collect cow dung from the second day of feeding, and collect continuously for more than 3 days. The collected cow dung is air-dried at room temperature, and the water content is controlled at 15-20%.

[0033] (3) Preparation of biochar: put the above-mentioned dried cow dung into a crucible, put it into an oven, bake at 65-70°C for 22-24 hours, and control the water content at 4-8%. Then the dried cow dung was put into the muffle furnace, and biochar was prepared by one-step slow pyrolysis. The pyrolysis condition is to raise the temperature to 600°C or 700°C at 20°C / min in a nitrogen atmosphere, and then cool down to room temperature naturally after 3 hours of pyrolysis. Take out the product, grind it through a 40-mes...

Embodiment 3

[0037] (1) Transabdominal transformation of corn stalks: Take fresh corn stalks, cut them into 2-3cm uniform pieces, mix them with 0.1% salt, and feed them to cattle as the only feed for more than 4 days.

[0038] (2) Cow dung collection and treatment: start to collect cow dung from the second day of feeding, and collect continuously for more than 3 days. The collected cow dung is air-dried at room temperature, and the water content is controlled at 15-20%.

[0039](3) Preparation of biochar: put the above-mentioned dried cow dung into a crucible, put it into an oven, and bake it at 65-70° C. for 22-24 hours, and control the water content at 4-8%. Then the dried cow dung was put into the muffle furnace, and biochar was prepared by one-step slow pyrolysis. The pyrolysis condition is to raise the temperature to 600°C or 700°C at 20°C / min in a nitrogen atmosphere, and then cool down to room temperature naturally after 3 hours of pyrolysis. Take out the product, grind it through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com