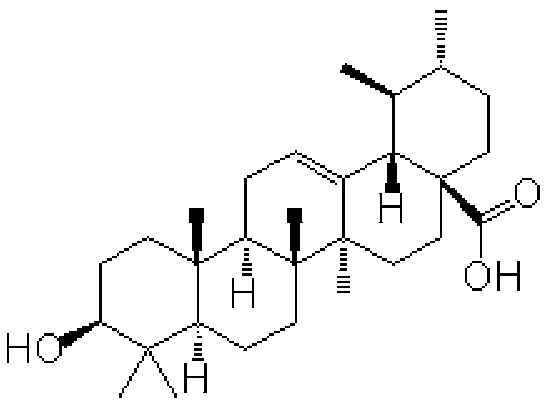

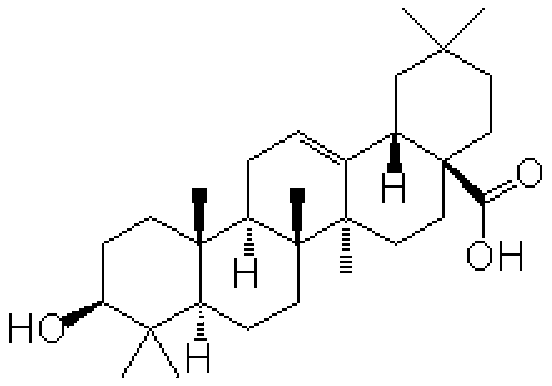

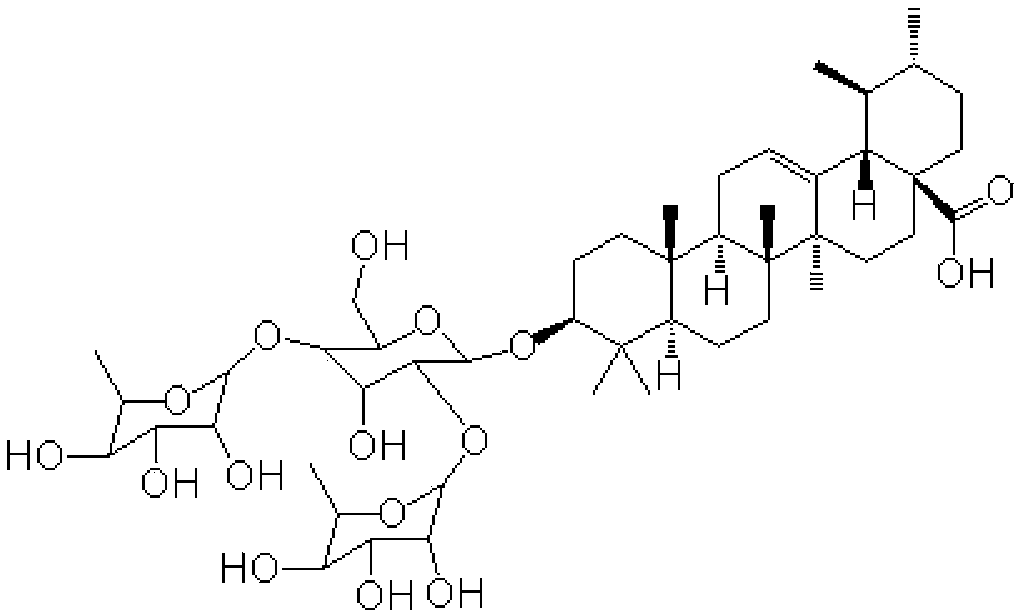

Extraction and purification method of triterpene acid in seabuckthorns, triterpene acid, triterpenoid saponin and application of triterpene acid and triterpenoid saponin

A purification method and technology of triterpenoid saponins are applied in the directions of chemical instruments and methods, applications, food ingredients containing natural extracts, etc., and can solve the problems of poor separation effect and low purity of ursolic acid and oleanolic acid, and achieve The effect of enhancing immunity, high purity and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] This embodiment provides a method for extracting and purifying triterpene acids in Seabuckthorn, comprising the following steps:

[0106] (a) Dry seabuckthorn pericarp at 75°C for 30 minutes, crush it to a particle size of 90 mesh, use 75% ethanol as the extractant, the mass ratio of seabuckthorn peel and 75% ethanol is 1:10, and ultrasonically extract for 30 minutes at room temperature to obtain the extract ;

[0107] (b) process extract with 1.5mol / L sodium hydroxide solution earlier, adjust pH to 11, then process extract with 1.5mol / L hydrochloric acid solution, adjust pH to 3, obtain ursolic acid and oleanolic acid solid, Rinse ursolic acid and oleanolic acid solids with water for 3 times, dissolve ursolic acid and oleanolic acid solids in 75% absolute ethanol to obtain a mixed solution;

[0108] (c) The macroporous resin is packed into a column, and the mass ratio of D101 macroporous resin and X-5 macroporous resin in the macroporous resin is 3:13, and ursolic aci...

Embodiment 2

[0111] This embodiment provides a method for extracting and purifying triterpene acids in Seabuckthorn, comprising the following steps:

[0112] (a) Dry seabuckthorn pericarp at 75°C for 30 minutes, crush it to a particle size of 90 mesh, use 75% ethanol as the extractant, the mass ratio of seabuckthorn peel and 75% ethanol is 1:10, and ultrasonically extract for 30 minutes at room temperature to obtain the extract ;

[0113] (b) process extract with 1.5mol / L sodium hydroxide solution earlier, adjust pH to 11, then process extract with 1.5mol / L hydrochloric acid solution, adjust pH to 3, obtain ursolic acid and oleanolic acid solid, Rinse ursolic acid and oleanolic acid solids with water for 3 times, dissolve ursolic acid and oleanolic acid solids in 75% absolute ethanol to obtain a mixed solution;

[0114] (c) The macroporous resin is packed into a column, the mass ratio of D101 macroporous resin and X-5 macroporous resin in the macroporous resin is 3:10, and ursolic acid an...

Embodiment 3

[0117] This embodiment provides a method for extracting and purifying triterpene acids in Seabuckthorn, comprising the following steps:

[0118] (a) Dry seabuckthorn pericarp at 75°C for 30 minutes, crush it to a particle size of 90 mesh, use 75% ethanol as the extractant, the mass ratio of seabuckthorn peel and 75% ethanol is 1:10, and ultrasonically extract for 30 minutes at room temperature to obtain the extract ;

[0119] (b) process extract with 1.5mol / L sodium hydroxide solution earlier, adjust pH to 11, then process extract with 1.5mol / L hydrochloric acid solution, adjust pH to 3, obtain ursolic acid and oleanolic acid solid, Rinse ursolic acid and oleanolic acid solids with water for 3 times, dissolve ursolic acid and oleanolic acid solids in 75% absolute ethanol to obtain a mixed solution;

[0120] (c) The macroporous resin is packed into a column, the mass ratio of D101 macroporous resin and X-5 macroporous resin in the macroporous resin is 1:15, and ursolic acid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com