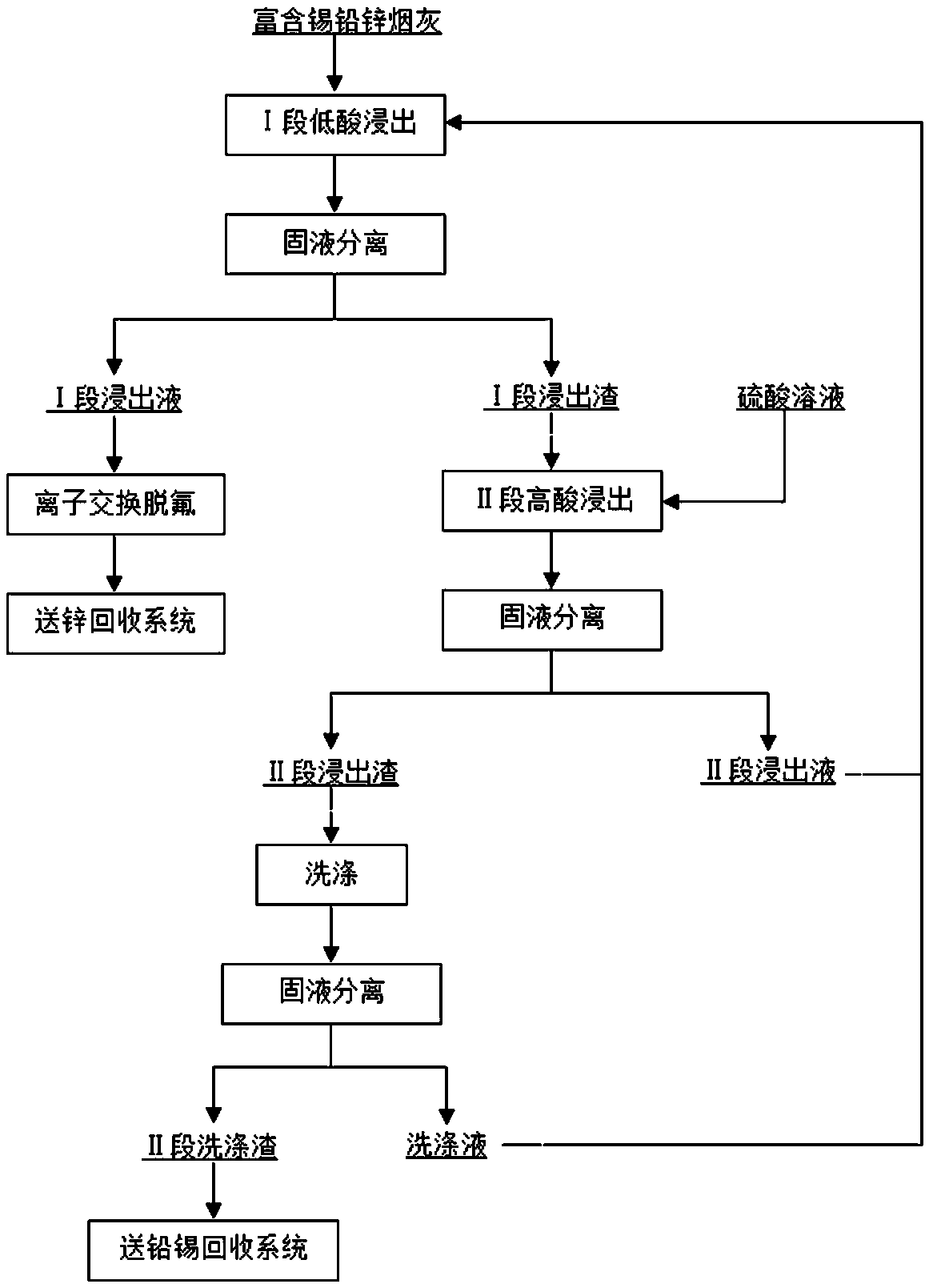

Method for comprehensively recovering zinc, lead and tin from tin-rich lead-zinc soot by adopting two-stage countercurrent sulfuric acid leaching

A low-acid leaching and high-acid leaching technology is applied in the field of recycling zinc, lead and tin to achieve the effects of reducing sulfuric acid consumption, environmental friendliness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The main components of the lead-tin-zinc-rich soot in this embodiment are: Zn16.36%, Pb13.96%, Sn24.28%. Mix 1000g of lead-tin-zinc-rich soot with sulfuric acid solution, carry out sulfuric acid leaching reaction under the conditions of sulfuric acid mass concentration 30g / L, liquid-solid ratio 3:1, temperature 80°C, and time 60min. stage leaching solution and stage I leaching residue. The leaching residue of stage I contains Zn13.80%, Sn34.09%, Pb20.12%, and the zinc leaching rate of stage I is 41.64%.

[0049] Mix the leaching residue of stage I with sulfuric acid solution, and carry out sulfuric acid leaching reaction under the conditions of sulfuric acid mass concentration 110g / L, liquid-solid ratio 3:1, temperature 80°C, and time 60min. After the reaction is completed, the leachate of stage II and The leaching residue of the second stage is washed to obtain the washing water and the washing slag of the second stage. The leaching residue of stage II contains Zn0.6...

Embodiment 2

[0051] The main components of the lead-tin-zinc-rich soot in this embodiment are: Zn13.87%, Pb12.46%, Sn27.43%. Mix 1000g of lead-tin-zinc-rich soot with sulfuric acid solution, carry out sulfuric acid leaching reaction under the conditions of sulfuric acid concentration of 20g / L, liquid-solid ratio of 5:1, temperature of 90°C, and time of 120min. stage leaching solution and stage I leaching residue. The leaching slag of stage I contains Zn12.23%, Pb11.57%, Sn43.13%, and the zinc leaching rate of stage I is 44.01%.

[0052] Mix the leaching residue of stage I with sulfuric acid solution, and carry out the sulfuric acid leaching reaction under the conditions of sulfuric acid mass concentration 120g / L, liquid-solid ratio 5:1, temperature 90°C, and time 120min. After the reaction is completed, the leachate of stage II and Stage II leaching slag. The leaching residue of stage II contains Zn0.83%, Pb28.09%, Sn54.08%. After two stages of leaching, the zinc leaching rate reached 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com