Quartz glass porous enzyme label plate manufacturing method and quartz glass enzyme label plate

A technology of quartz glass and a manufacturing method, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of low stability, easy surface oxidation, low ultraviolet transmission, etc., and achieves excellent transmission of ultraviolet spectrum, visible light and infrared spectrum. Performance, corrosion resistance enhancement, effect of high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0037] Specific embodiment one: the manufacture method of quartz glass multiwell microplate

[0038] The manufacture method of quartz glass multiwell microplate mainly comprises following process steps:

[0039] (1) Preparation of quartz glass plate: The preparation method of quartz glass plate includes the following process steps:

[0040] Prepare qualified quartz glass whose qualified quartz glass SiO 2 The mass percentage is not less than 99.99%, transparent and free of bubbles, and the transmittance of visible light and ultraviolet light is not less than 90%;

[0041] Soak the qualified quartz glass ore in hydrochloric acid with a mass percentage of 10%~20% for more than 20 hours, then rinse it with water, and finally clean it with deionized water, heat it to 900~950°C, keep it warm for 3~5 hours Quickly pour the quartz glass ore into cold water and crush it;

[0042] The crushed quartz glass is crushed with a grinder, and then sieved. The sieved quartz glass particles...

specific Embodiment 2

[0052] Specific embodiment two: a kind of quartz glass microplate

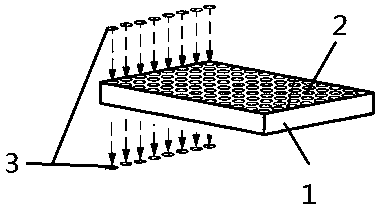

[0053] Utilize a kind of quartz glass microplate prepared by specific embodiment 1, microplate 1 is cuboid shape, and its length is 120 ~ 130 millimeters, wide 80 ~ 90 millimeters, thick 10 ~ 15 millimeters on microplate horizontally and vertically side by side A light-transmitting groove 2 is provided, and the light-transmitting groove 2 is a cylindrical through hole, and the light-transmitting groove 2 is used for storing liquid materials.

[0054] In order to facilitate the observation of the internal state of the light-transmitting groove, the top and bottom of the light-transmitting groove 2 are respectively provided with lenses 3 .

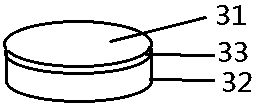

[0055] In order to facilitate the installation of the lens, the lens 3 is a button type, and the lens 3 is a cylindrical shape with an opening on one side, which includes a bottom surface 31 and a side wall 32, the diameter of the side wall is consistent with the diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com