Olive residue organic fertilizer, preparation method thereof and application of organic fertilizer

A technology of olive pomace and organic fertilizer, applied in the field of organic fertilizer, can solve the problem of lack of rapid and effective treatment of olive pomace, and achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

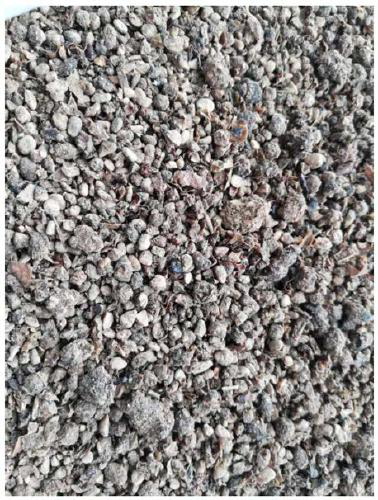

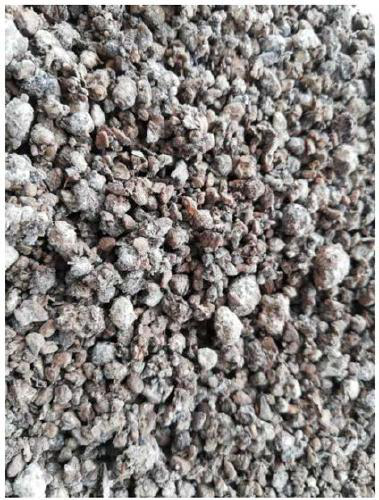

Image

Examples

preparation example Construction

[0033] The invention provides a kind of preparation method of olive pomace organic fertilizer, comprises the following steps:

[0034] (1) adding a nitrogen source substance to the olive pomace, adjusting the C / N ratio to 25:1-30:1 to obtain the olive pomace mixture;

[0035] (2) mixing the microbial starter, wheat bran and corn according to the mass ratio of 1:2.4 to 3:1.6 to 2 to obtain the starter mixture;

[0036] (3) According to the mass ratio of the olive pomace in the olive pomace mixture to the microbial starter in the starter mixture of 100:0.2 to 0.4, the olive pomace mixture is mixed with the starter mixture, and the water content is adjusted to 50 to 55%, Obtain fermentation raw materials;

[0037] (4) Composting and fermenting the fermented raw materials for 20-30 days under an environment of 18-28°C, humidity 10-15%, and oxygen content 8-15%, to obtain olive pomace organic fertilizer;

[0038] There is no time sequence limitation between the step (1) and the s...

Embodiment 1

[0067] Get 1 ton of olive pomace (water content 60%) and mix with urea 17.46kg, diammonium phosphate 22.4kg to obtain olive pomace mixture; get Gymboree fertilizer starter 4kg, wheat bran 9.6kg and corn 6.4kg to mix to obtain a fermentation mixture; The olive pomace mixture is completely mixed with the fermented mixture, and the water content is adjusted to 54 percent to obtain the fermented raw material.

[0068] Pile the fermentation raw materials into a pile with a height of 1.5m, and ferment in an environment of 20°C, humidity 10%, and oxygen content 8%. When the temperature is above 58-60°C, turn the pile once, and keep the water content of the fermentation raw materials at Between 50% and 55%; when the temperature of the fermented raw material heap starts to decrease from the high temperature period and enters the later stage of fermentation, the moisture content of the fermented raw material is controlled below 30% until the end of the fermentation, and a total of 20 day...

Embodiment 2

[0070] Get 1 ton of olive pomace (water content 60%) and mix with urea 17.46kg, diammonium phosphate 22.4kg to obtain olive pomace mixture; get EM bacterial agent 3kg, wheat bran 7.2kg and corn 4.8kg and mix to obtain a fermentation mixture; The slag mixture is completely mixed with the fermentation mixture, and the water content is adjusted to 54% to obtain the fermentation raw material.

[0071] Pile the fermentation raw materials into a pile with a height of 1.5m, and ferment in an environment of 20°C, humidity 10%, and oxygen content 8%. Between 50% and 55%; when the temperature of the fermented raw material heap begins to decrease from the high temperature period and enters the late stage of fermentation, the moisture content of the fermented raw material is controlled below 30% until the end of the fermentation, and a total of 20 days of fermentation is obtained to obtain organic olive pomace. Fat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com