A kind of hydrophilic monomer and aqueous acrylic acid dispersion prepared by it

A technology of water-based acrylic and hydrophilic monomers, applied in the field of coatings, can solve the problems of coating film gloss, fog, water resistance decline, ion stability, etc., to reduce VOC emissions, improve gloss, and improve ion stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A hydrophilic monomer, the synthesis of which includes the following steps: put 30 parts by mass of ethylene glycol and 20 parts by mass of maleic acid into a reactor, start stirring, react at a temperature of 120°C for 2 hours, and detect the acid value until the initial When the acid value is 1 / 2, the temperature is lowered, filtered, and discharged to obtain a hydrophilic monomer.

[0030] The preparation method of present embodiment aqueous acrylic acid dispersion comprises following formula and technology:

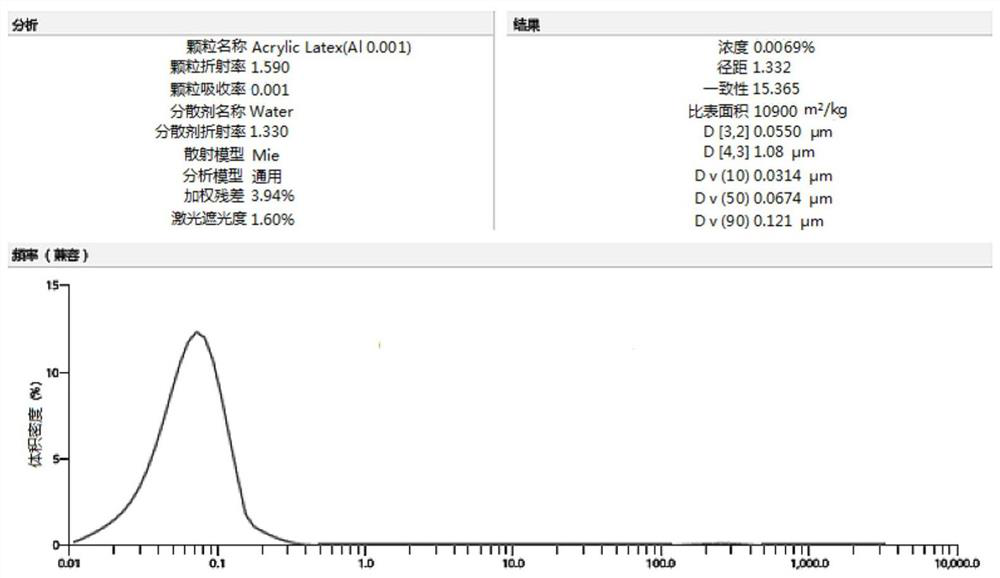

[0031] Add 20g of propylene glycol methyl ether into the reaction kettle and raise the temperature to 117°C; add 7g of methyl methacrylate, 20g of hydroxypropyl acrylate, 29g of styrene, 16g of butyl acrylate, 3g of acrylic acid, 5g of self-made hydrophilic monomer, peroxide 1.6 g of tert-butyl benzoate was mixed evenly and dropped into the reaction kettle within 4 hours. After the dropwise addition, it was kept warm for 1 hour, and 0.2 g of tert-butyl peroxybe...

Embodiment 2

[0033] A hydrophilic monomer, the synthesis of which includes the following steps: put 67 parts by mass of MPEG200 and 33 parts by mass of maleic anhydride into a reactor, start stirring, react at a temperature of 140°C for 1.8 hours, and detect the acid value to the initial acid Lower the temperature to one-half of the value, filter, and discharge to obtain a hydrophilic monomer.

[0034] The reaction mechanism of the hydrophilic monomer in this embodiment is: maleic anhydride is ring-opened by MPEG200 containing hydroxyl at a certain temperature to produce a hydrophilic monomer with a double bond, PEG200 and carboxyl, in which the double bond It can be polymerized with acrylic monomers, PEG200 has non-ionic hydrophilicity, and carboxyl group has ionic hydrophilicity, so that acrylic resin can be dispersed in water.

[0035] The preparation method of present embodiment aqueous acrylic acid dispersion comprises following formula and technology:

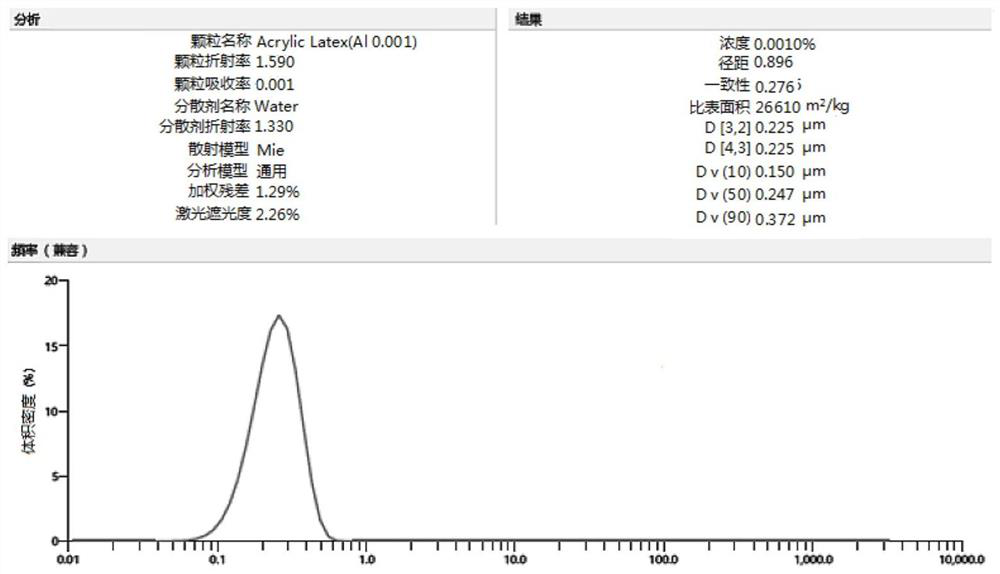

[0036] Add 20g of propylene g...

Embodiment 3

[0038] A hydrophilic monomer, the synthesis of which includes the following steps: put 80 parts by mass of ethylene glycol and 70 parts by mass of methylene succinic acid into a reactor, start stirring, react at a temperature of 180°C for 1.5 hours, and detect the acid When the acid value reaches 1 / 2 of the initial acid value, the temperature is lowered, filtered, and discharged to obtain a hydrophilic monomer.

[0039] The preparation method of present embodiment aqueous acrylic acid dispersion comprises following formula and technology:

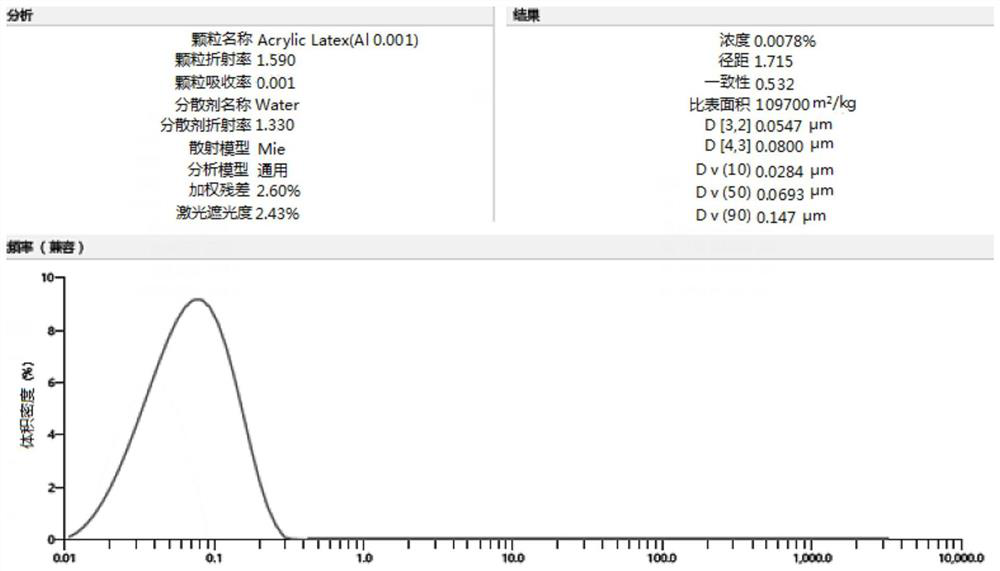

[0040] Add 20g of propylene glycol methyl ether into the reaction kettle and raise the temperature to 117°C; add 10g of methyl methacrylate, 15g of hydroxypropyl acrylate, 24g of styrene, 18g of butyl acrylate, 3g of acrylic acid, 10g of self-made hydrophilic monomer, peroxide 1.6 g of tert-butyl benzoate was mixed evenly and dropped into the reaction kettle within 4 hours. After the dropwise addition, it was kept warm for 1 hour, and 0.2 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com