Method for cleaning comprehensive utilization of shrimp and crab shell waste

A technology for waste and shrimp and crab shells, which is applied in the field of clean and comprehensive utilization of shrimp and crab shell waste, can solve the problems that soluble protein or amino acid solution cannot be formed, and solid protein is difficult to be absorbed and utilized by plants, so as to reduce waste discharge, Effect of reducing processing difficulty and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1. The method of cleaning and comprehensive utilization of shrimp and crab shell waste

[0044] 1. Steam explosion

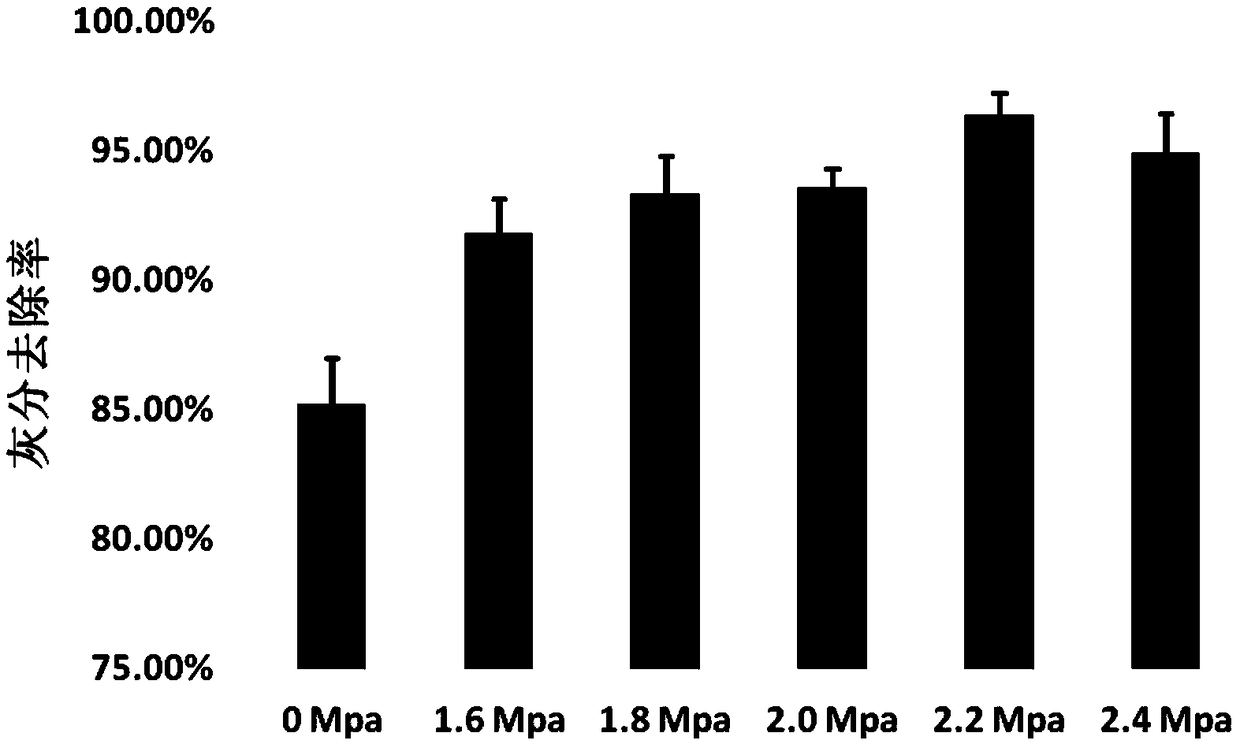

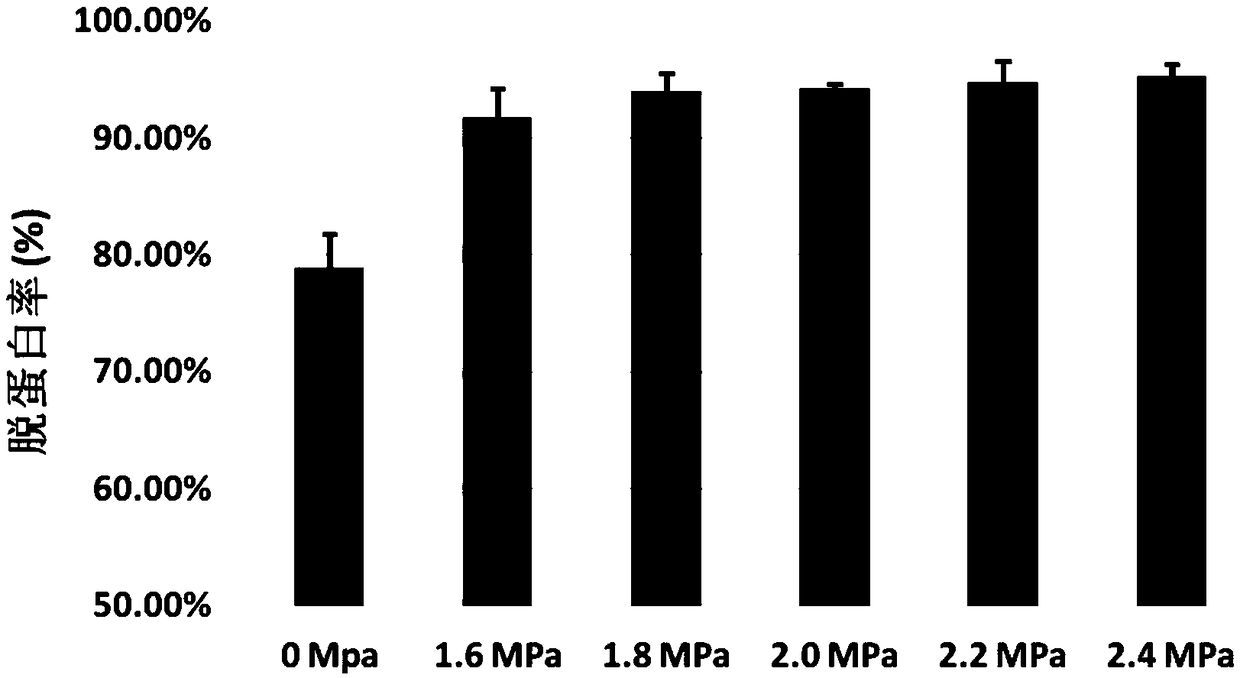

[0045] After soaking 1kg of shrimp shell or crab shell in water for 3 hours, put it into the steam explosion equipment for blasting treatment. The set processing pressure is 1.4MPa-2.4MPa, and the processing time is 60s-600s. After the treatment is completed, dry at 50-80°C using a blast drying oven.

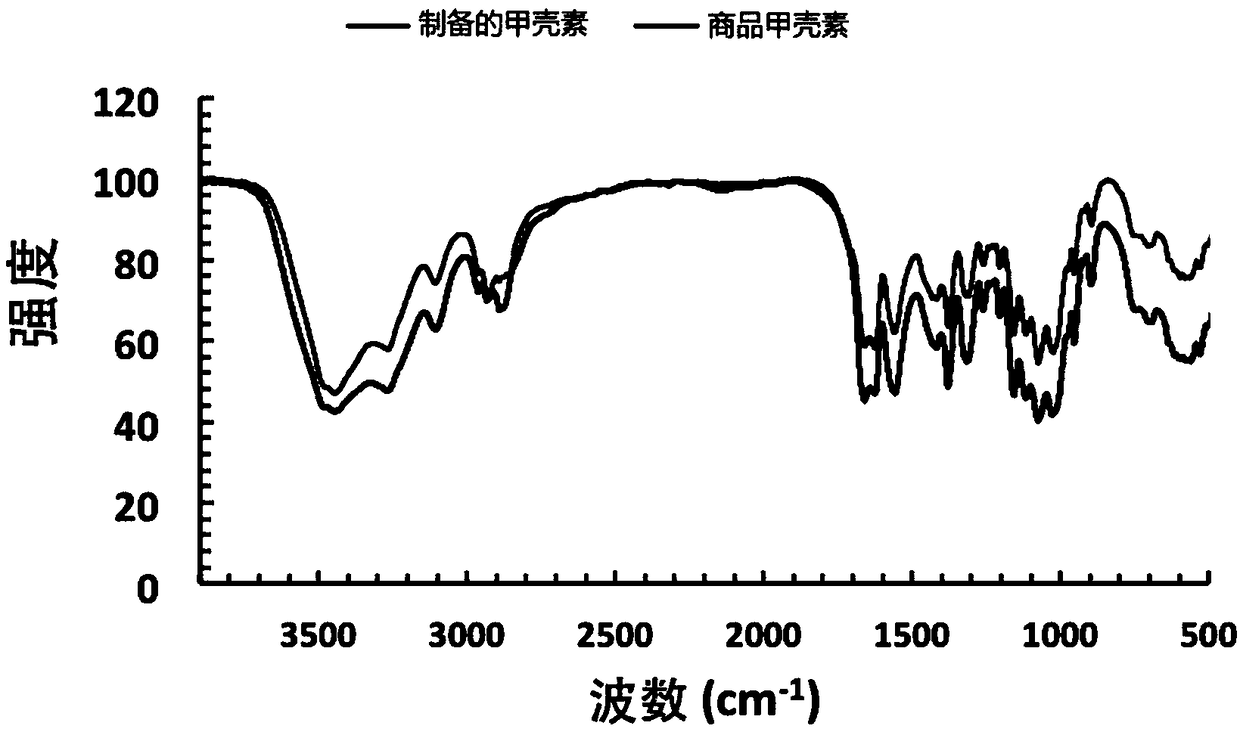

[0046] XRD (X-ray Diffraction) analysis was carried out on the shrimp shells treated by steam explosion, and the shrimp shells not treated by steam explosion were used as a control. It was found that the crystallinity of shrimp shells after steam explosion treatment was significantly reduced, and the crystallinity continued to decrease with the increase of pressure. The results show that the steam explosion technique can damage the crystal structure inside the shrimp shell to a certain extent, thereby reducing the binding degree of the three c...

Embodiment 2

[0091] Embodiment 2. Plant fertilizer promotes the growth of wheat

[0092]The liquid plant fertilizer prepared in Example 1 was diluted 300, 400, 500, and 600 times respectively, and distilled water was used as a control (ck) to study the effect of the above-mentioned plant fertilizer on wheat seed germination and growth. The wheat seeds used are Jingdong 22, a known variety, from Beijing Xiaotangshan National Precision Agriculture Demonstration Base.

[0093] The specific steps are:

[0094] Soak the wheat seeds with 0.3% potassium permanganate solution for 5 minutes, rinse them with distilled water until they are colorless, divide them into 5 groups, and each group has 100 wheat seeds. The 5 groups of wheat seeds were soaked in the above-mentioned solutions with different concentrations for 12 hours to allow the seeds to fully imbibition. Afterwards, the seeds were respectively planted in sterilized soil and cultured in an artificial climate box under the following condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com