Modified epoxy resin and preparation and application thereof

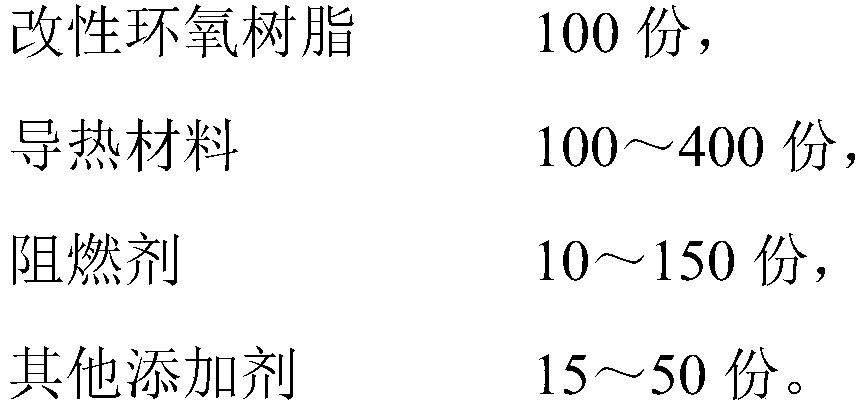

A technology of epoxy resin modification, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problems of photoinitiator being sensitive to oxygen, poor adhesion, etc., and achieve control of curing crosslinking time , fast curing, to ensure the effect of curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

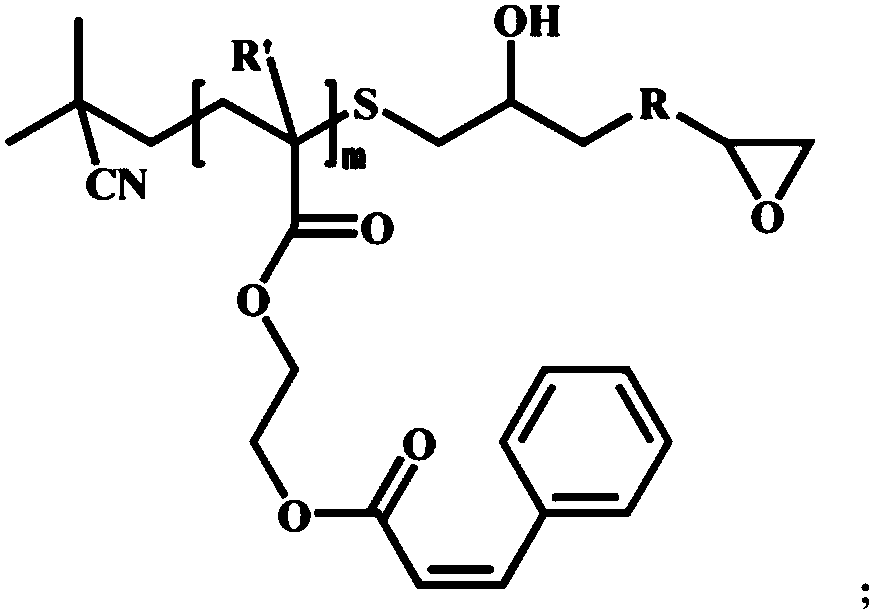

[0046] Embodiment 1, the synthesis of mercapto polycinnamoyl ethyl methacrylate

[0047] The present embodiment provides a kind of polycinnamoyl ethyl methacrylate and its synthetic method, and the synthetic method comprises the following steps:

[0048] (1) Take 1 part of azobisisobutyronitrile initiator, 600 parts of hydroxyethyl methacrylate, 10 parts of benzyl dithiobenzoate, and 100 parts of methanol, and react at 80°C for 1 hour under nitrogen protection , to obtain poly(hydroxyethyl methacrylate) containing disulfide at the end of the polymer;

[0049](2) 100 parts of poly(hydroxyethyl methacrylate) containing disulfide at the end obtained in step (1), 300 parts of pyridine and 120 parts of cinnamoyl chloride were reacted at 25°C for 24 hours to obtain disulfide at the end Polyester cinnamoyl chloride ethyl methacrylate;

[0050] (3) Under the protection of nitrogen, mix 100 parts of the product obtained in step (2) (poly-cinnamoyl chloride ethyl methacrylate with a ...

example 2

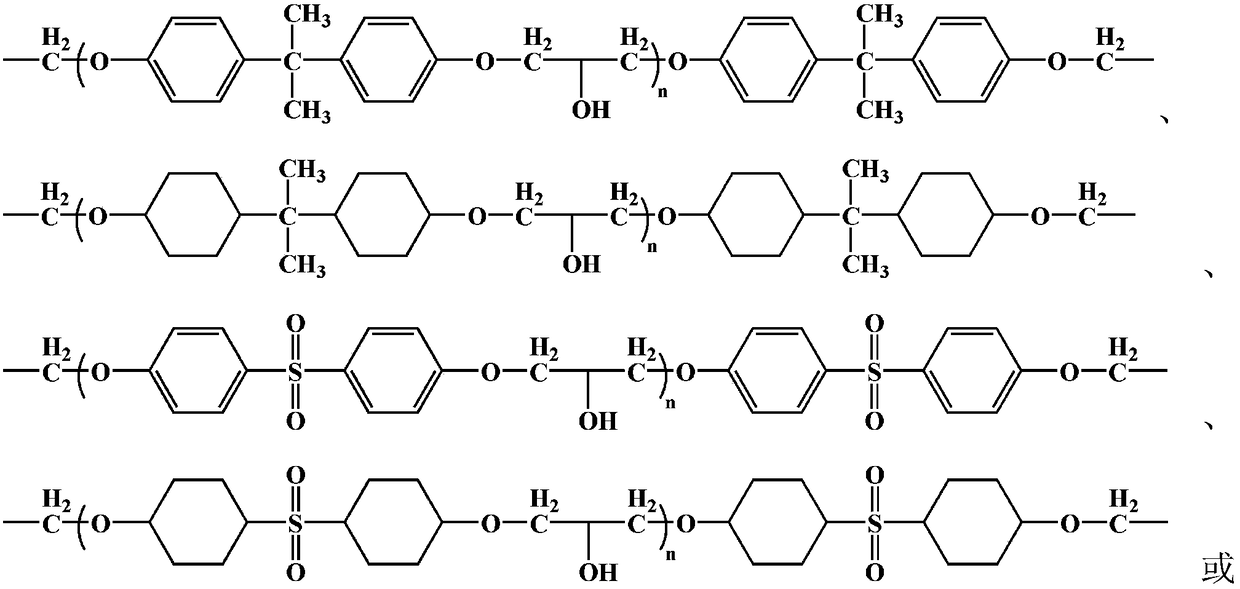

[0053] Example 2, the synthesis of chemically modified epoxy resin

[0054] This embodiment provides a kind of chemically modified epoxy resin and its synthetic method, and this synthetic method comprises the following steps:

[0055] Get 100 parts of epoxy resin (select bisphenol A type epoxy resin, molecular weight 4000) and join in the reactor, add 30 parts of mercaptopoly-cinnamoyl chloride ethyl methacrylates (synthesized in embodiment 1) and 3 parts under nitrogen protection The tetrahydrofuran solution dissolved with LiOH was stirred at room temperature for 2 hours and then vacuum-dried to obtain a chemically modified epoxy resin, which was designated as chemically modified epoxy resin A. The mass of the LiOH is 0.1-1% of the total mass of the epoxy resin and the mercapto polyethyl cinnamoyl chloride methacrylate.

[0056] The chemically modified epoxy resin A obtained in this example has a viscosity between 4000 and 10000 cps.

example 3

[0057] Example 3, the synthesis of chemically modified epoxy resin (B)

[0058] This embodiment provides a kind of chemically modified epoxy resin and its synthetic method, and this synthetic method comprises the following steps:

[0059] Get 100 parts of epoxy resin (select bisphenol F type epoxy resin, molecular weight 6000) and join in the reactor, add 45 parts of mercaptopoly-cinnamoyl chloride ethyl methacrylates (synthesized in embodiment 1) and 7 parts under nitrogen protection dissolved in AlCl 3 THF solution, stirred at room temperature for 2.5 hours and then vacuum-dried to obtain a chemically modified epoxy resin, denoted as chemically modified epoxy resin B. AlCl 3 The mass is 0.1% to 1% of the total mass of epoxy resin and mercapto polyethyl cinnamoyl chloride methacrylate.

[0060] The chemically modified epoxy resin B obtained in this example has a viscosity between 8000-14000 cps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com