Photo-functional composite, preparation method thereof and serial photocatalytic application

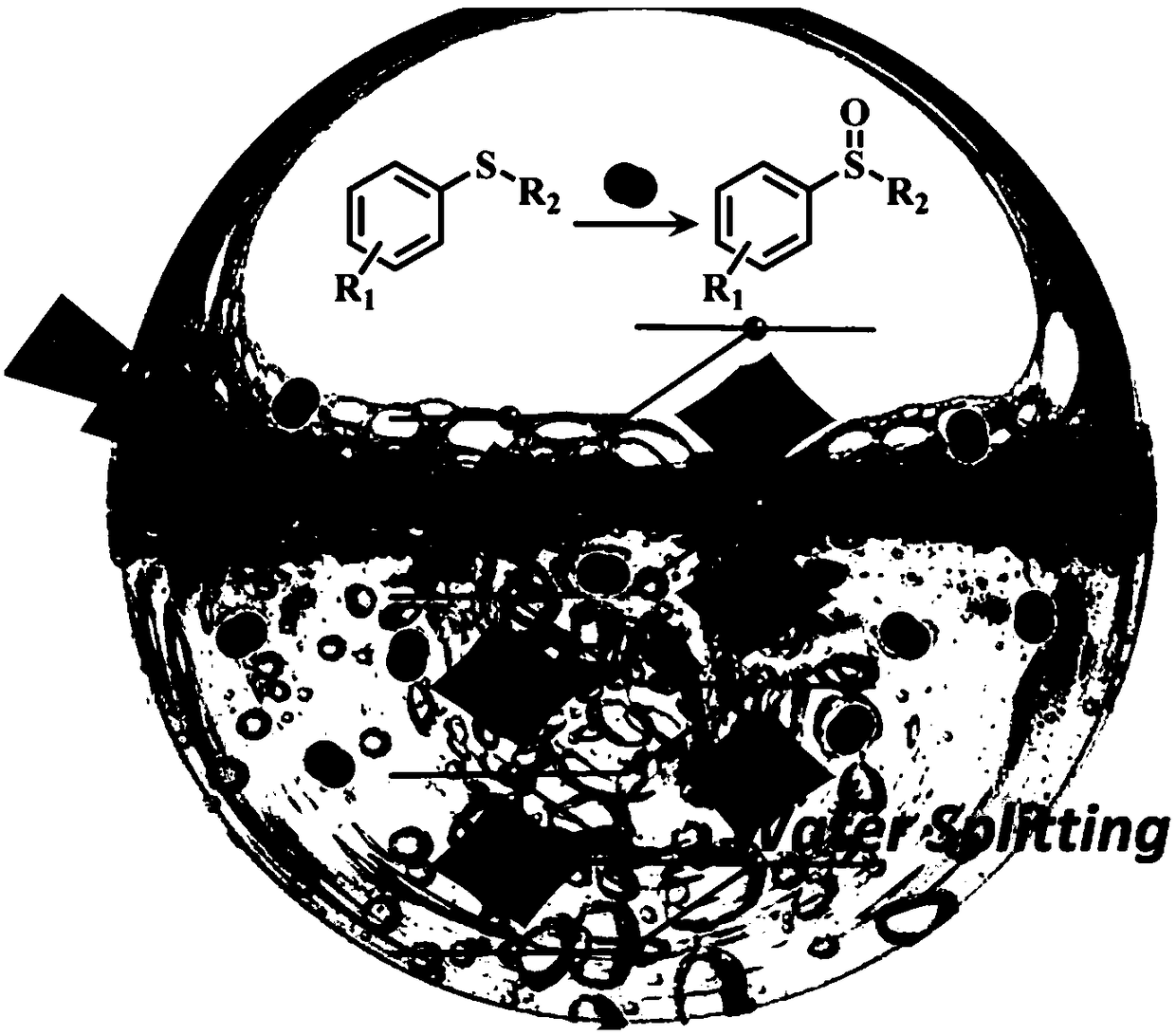

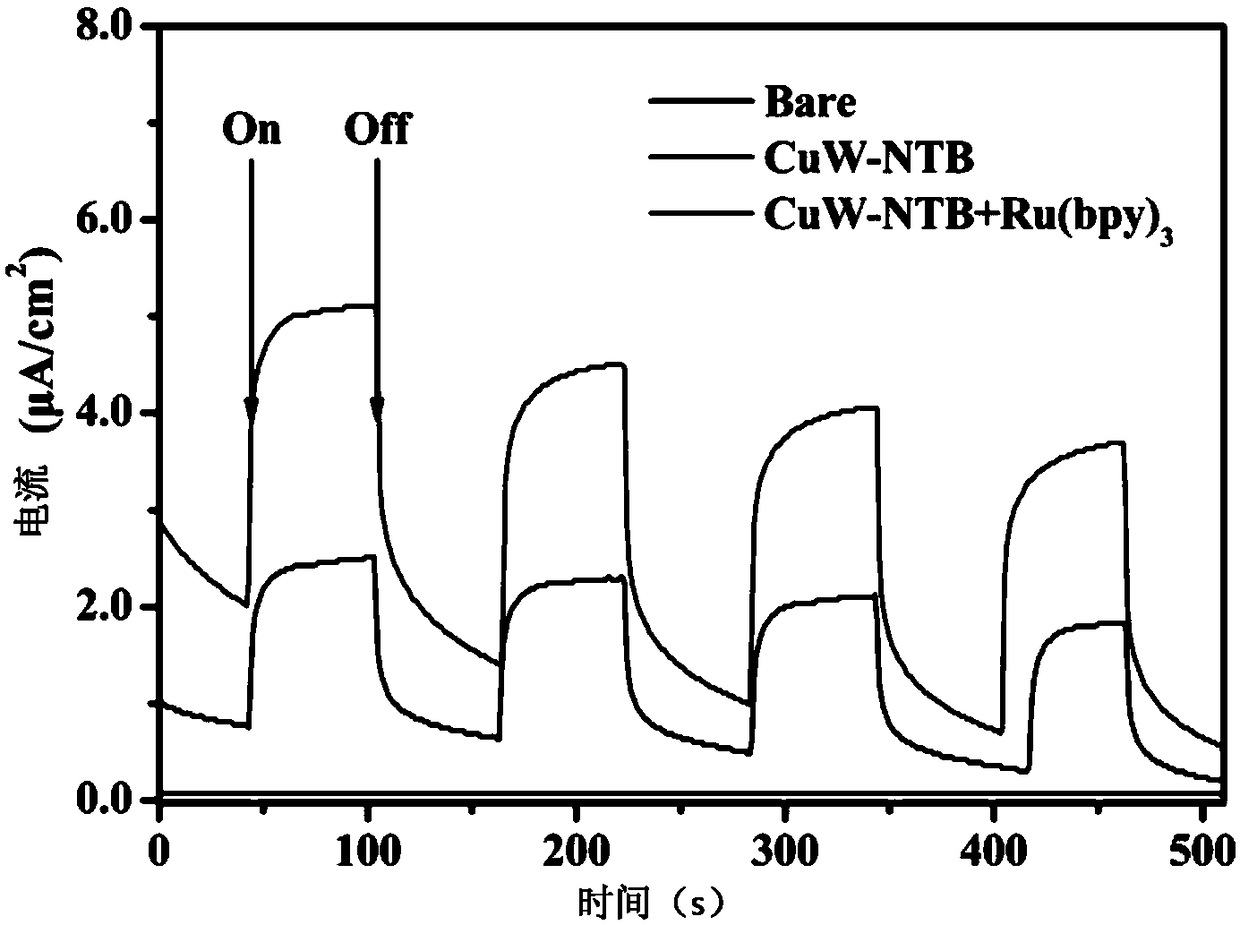

A composite material and functional technology, applied in the field of photocatalytic materials, can solve the problems of unseen catalytic multi-component series reactions, harsh reaction conditions, expensive oxidants, etc., to improve photocatalytic efficiency and reusability, reaction The effect of mild conditions and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Another aspect of the embodiments of the present invention provides the aforementioned preparation method of the photofunctional composite material, which includes: polyoxometalate, copper salt, and NTB in a molar ratio of 1:5:5 to 1:5:10 The ligands are fully mixed in the solvent, and then cured at 110-130° C. for 60-84 hours to obtain orange-yellow block crystals, which are the optical functional composite materials.

[0036] In some embodiments, the molar ratio of the polyoxometalate, copper salt and NTB ligand is (0.01-0.05): (0.05-0.10): (0.05-0.10), specifically, the polyoxometalate The amounts of salt, copper salt and NTB ligand are 0.01-0.05 mmol, 0.05-0.10 mmol and 0.05-0.10 mmol, respectively.

[0037] Further, the copper salt includes copper nitrate hydrate, preferably copper nitrate trihydrate, but not limited thereto.

[0038] Further, the polyoxometalates include (TBA) 4 [W 10 o 32 ], but not limited to this.

[0039] Further, the solvent includes DMF, ...

Embodiment 1

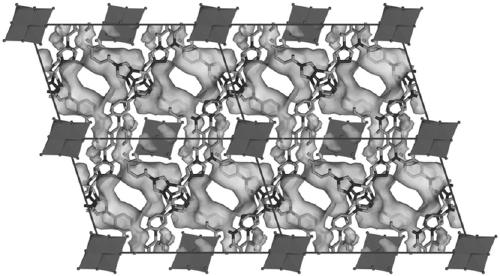

[0052] Example 1: Preparation of photofunctional POM@PCP composite material

[0053] Will (TBA) 4 [W 10 o 32 ] (33.2mg, 0.01mmol), Cu(NO 3 ) 2 ·3H 2 O (12.1mg, 0.05mmol) and NTB (22.3mg, 0.05mmol) were added to a mixture of N,N-dimethylformamide (DMF, 2.0mL) and water (0.5mL) for stirring, and 1mol· L –1 HCl adjusted the pH of the system to 2.6, stirred at room temperature for 20 minutes, then added the above suspension into a 25mL polytetrafluoroethylene reactor, baked at 120°C for 72 hours, and finally cooled to room temperature to obtain orange Blocky crystals were washed 3 times with DMF and dried at room temperature. The yield was about 49%.

Embodiment 2

[0054] Example 2: Preparation of photofunctional POM@PCP composite material

[0055] Will (TBA) 4 [W 10 o 32 ] (33.2mg, 0.01mmol), Cu(NO 3 ) 2 ·3H 2 O (12.1mg, 0.05mmol) and NTB (44.6mg, 0.10mmol) were added to a mixture of N,N-dimethylformamide (DMF, 3.0mL) and water (2.0mL) for stirring, and 1mol· L –1 HCl adjusted the pH of the system to 2.5, stirred at room temperature for 30 minutes, then added the above suspension into a 25mL polytetrafluoroethylene reactor, baked at 110°C for 84 hours, and finally cooled to room temperature to obtain orange Blocky crystals were washed 3 times with DMF and dried at room temperature. The yield was about 51%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com