Water-based middle coating high in stone-chip resistance, preparation method and application

A technology with high stone resistance and performance, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of reduced VOC emissions, unqualified stone resistance performance, poor mechanical properties, etc. Efficiency improvement, guaranteed stone chip resistance, gloss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

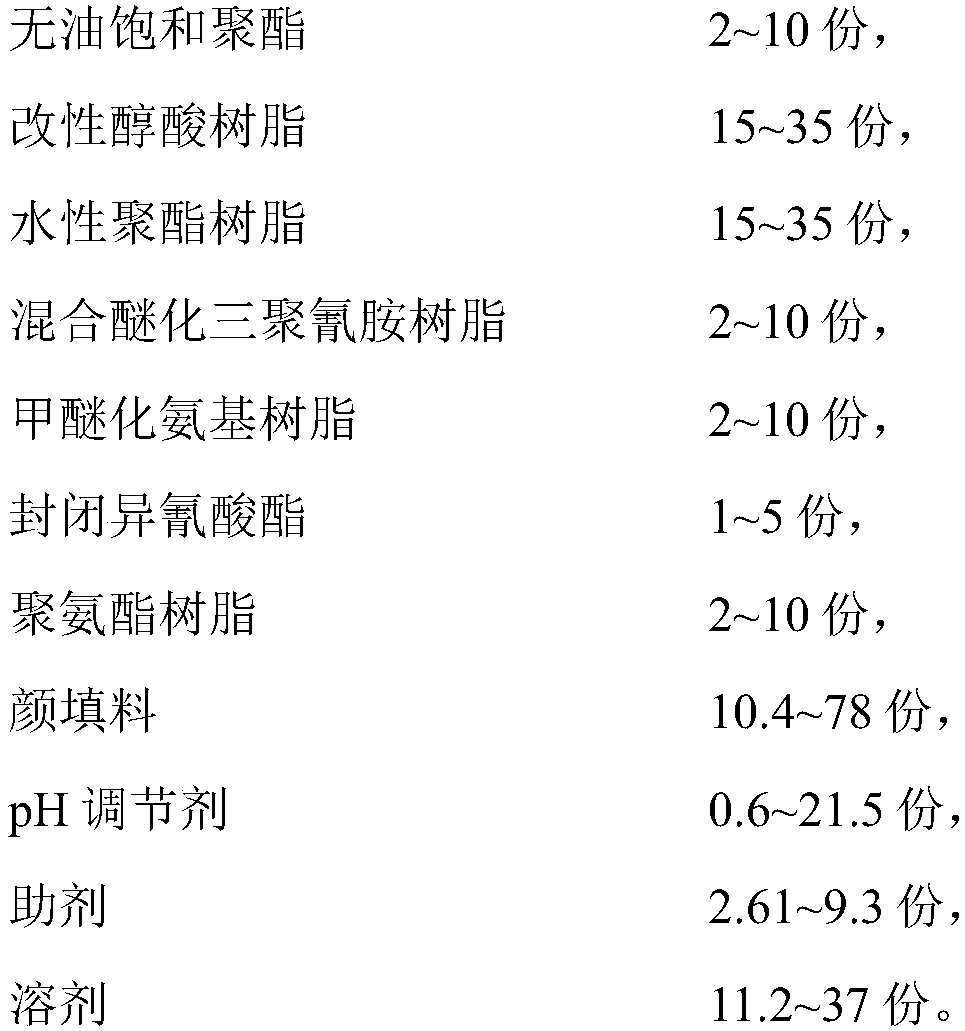

[0058] The reagents and consumption used in embodiment are as shown in table 1:

[0059] Table 1

[0060]

[0061]

[0062] Step 1: Sanding

[0063] Take a water-based special container, and confirm the shrinkage cavity test result after cleaning. After the shrinkage cavity is qualified, add oil-free saturated polyester, solvent diethylene glycol butyl ether, and a DMEA solution with a pH regulator concentration of 10% according to the parts by weight in Table 1. ;

[0064] Start stirring to 400RPM, after stirring for 5 minutes, add pure water (ED grade), DISPERBYK-180 wetting and dispersing agent and TEGO Dispers 655, co-solvent PRIMEPOL PX-1000, dispersion stabilizer, mixed etherified melamine resin while stirring , the feeding interval between each material is 5 minutes, after the feeding is completed, stir at a speed of 600-800RPM for 15 minutes;

[0065] Stir at a speed of 600-800RPM, continue to add anti-cratering agent GK-19, fumed silica, carbon black, titaniu...

Embodiment 2

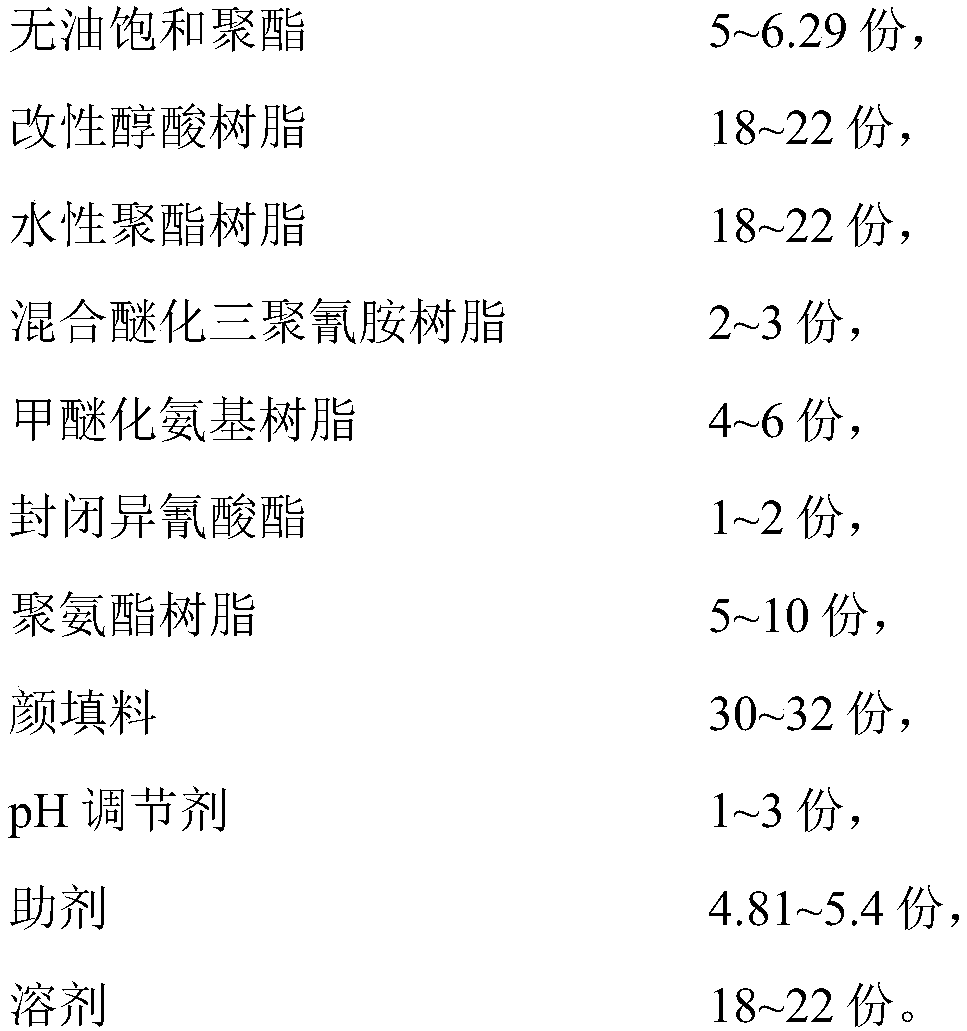

[0083] The reagents and consumption used in embodiment are as shown in table 2:

[0084] Table 2

[0085]

[0086]

[0087]

[0088] Step 1: Sanding

[0089] Take a water-based special container, confirm the shrinkage cavity test result after cleaning, and add oil-free saturated polyester, solvent diethylene glycol butyl ether, and a DMEA solution with a pH regulator concentration of 10% according to the parts by weight in Table 2 after the shrinkage cavity is qualified. ;

[0090] Start stirring to 400RPM. After stirring for 5 minutes, add pure water (ED grade), DISPERBYK-192 wetting and dispersing agent and BORCHI GEN1252, co-solvent PRIMEPOL PX-1000, dispersion stabilizer, mixed etherified melamine resin while stirring, The feeding interval between each material is 5 minutes. After the feeding is completed, stir at a speed of 600-800 RPM for 15 minutes;

[0091] Stir at a speed of 600-800RPM, continue to add anti-cratering agent GK-19, fumed silica, carbon black...

Embodiment 3

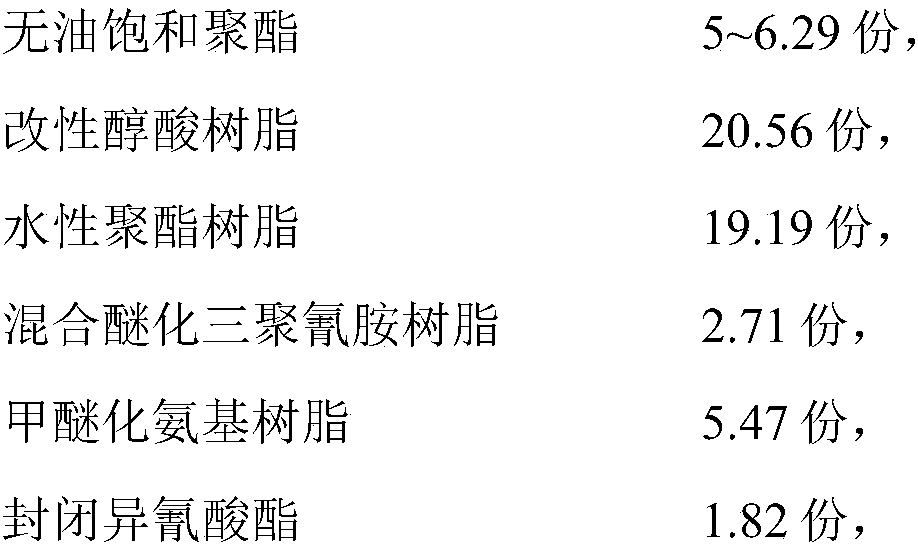

[0109] The reagents and consumption used in embodiment are as shown in table 3:

[0110] table 3

[0111]

[0112]

[0113] Step 1: Sanding

[0114]Get the water-based special container, confirm the shrinkage cavity test result after cleaning, and add oil-free saturated polyester, solvent ethylene glycol butyl ether, and a DMEA solution with a pH regulator concentration of 10% according to the parts by weight in Table 3 after the shrinkage cavity is qualified;

[0115] Start stirring to 400RPM, after stirring for 5 minutes, add pure water (ED grade), DISPERBYK-190 wetting and dispersing agent and TEGO WET 280, co-solvent PRIMEPOL PX-1000, dispersion stabilizer, mixed etherified melamine resin while stirring , the feeding interval between each material is 5 minutes, after the feeding is completed, stir at a speed of 600-800RPM for 15 minutes;

[0116] Stir at a speed of 600-800RPM, continue to add anti-cratering agent GK-19, fumed silica, carbon black, titanium dioxide,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com