Laundry soap and manufacturing process thereof

A manufacturing process and technology for laundry soap, which are applied in the directions of soap detergent and other compounding agents, detergent compositions, detergent compounding agents, etc., can solve the problems such as difficulty in rinsing clothes, unsuitability for continuous use, waste of laundry soap, etc., Achieve the effect of improving long-term cleaning ability, good lipophilicity and thickening effect, and not easy to yellow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Laundry soap, the components included and their corresponding parts by weight are shown in Table 1, and are manufactured and obtained through the following steps:

[0056] Step 1, crushing and stirring the soap particles, then adding whitening agent, chelating agent, and forming aids, and fully mixing to form the first mixture;

[0057]Step 2, mixing the glycerin with the enzyme additive stabilizer evenly, then adding the enzyme additive, and mixing thoroughly to form a second mixture;

[0058] Step 3, adding the second mixture in step 2 to the first mixture obtained in step 1, mixing thoroughly, grinding, stripping, cutting into pieces, and drying the soap to obtain laundry soap with a pH value of 6.0-7.5.

[0059] Wherein, the enzyme auxiliary agent is protease;

[0060] The chelating agent is composed of tetrasodium EDTA and etidylic acid with a ratio of parts by weight of 0.8:1.1;

[0061] The enzyme auxiliary agent stabilizer is composed of acetamid...

Embodiment 2-5

[0063] Embodiment 2-5: Laundry soap. The difference from Embodiment 1 is that the components and their corresponding parts by weight are as shown in Table 1. Wherein, the nonionic surfactant is coconut oil fatty acid monoethanolamide. Add the essence in step one and mix well, and add coconut oil fatty acid monoethanolamide in step two and mix well.

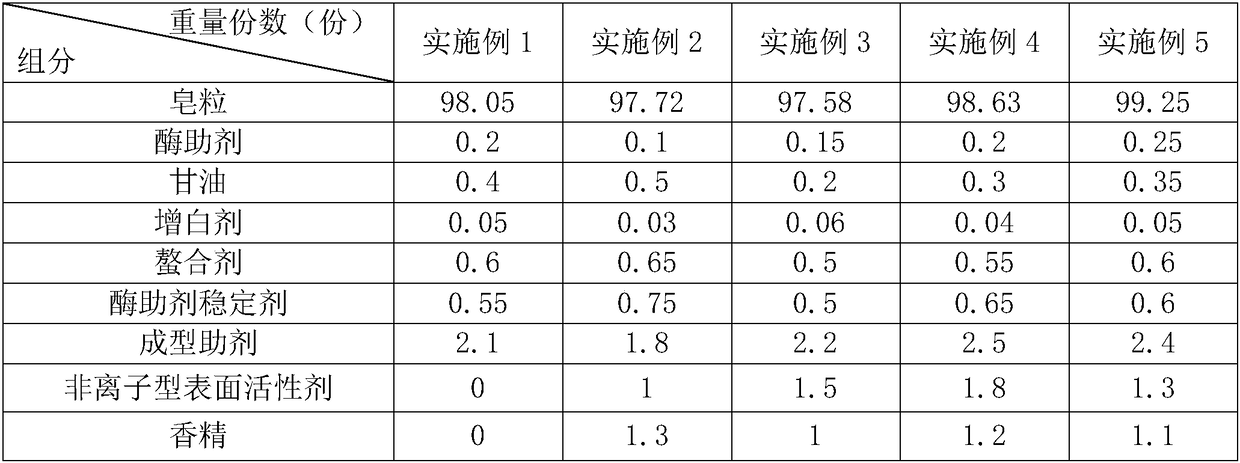

[0064] Components and corresponding parts by weight thereof included in Table 1 embodiment 1-5

[0065]

Embodiment 6

[0066] Embodiment 6: Laundry soap, the difference from Example 2 is that the enzyme auxiliary agent stabilizer consists of 4-formylphenylboronic acid, 4-acetylphenylboronic acid, acetamido Phenylboronic acid, 10% citric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com