Microwave fluidized roasting-leaching method for reinforcing high phosphorous iron ore iron-extracting and phosphorus-reducing

A fluidized roasting and iron ore technology, which is applied in the field of mineral processing, can solve the problem that the separation index of high-phosphorus oolitic hematite is not significant, and achieve the development and utilization of resources and high efficiency, improvement effects, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

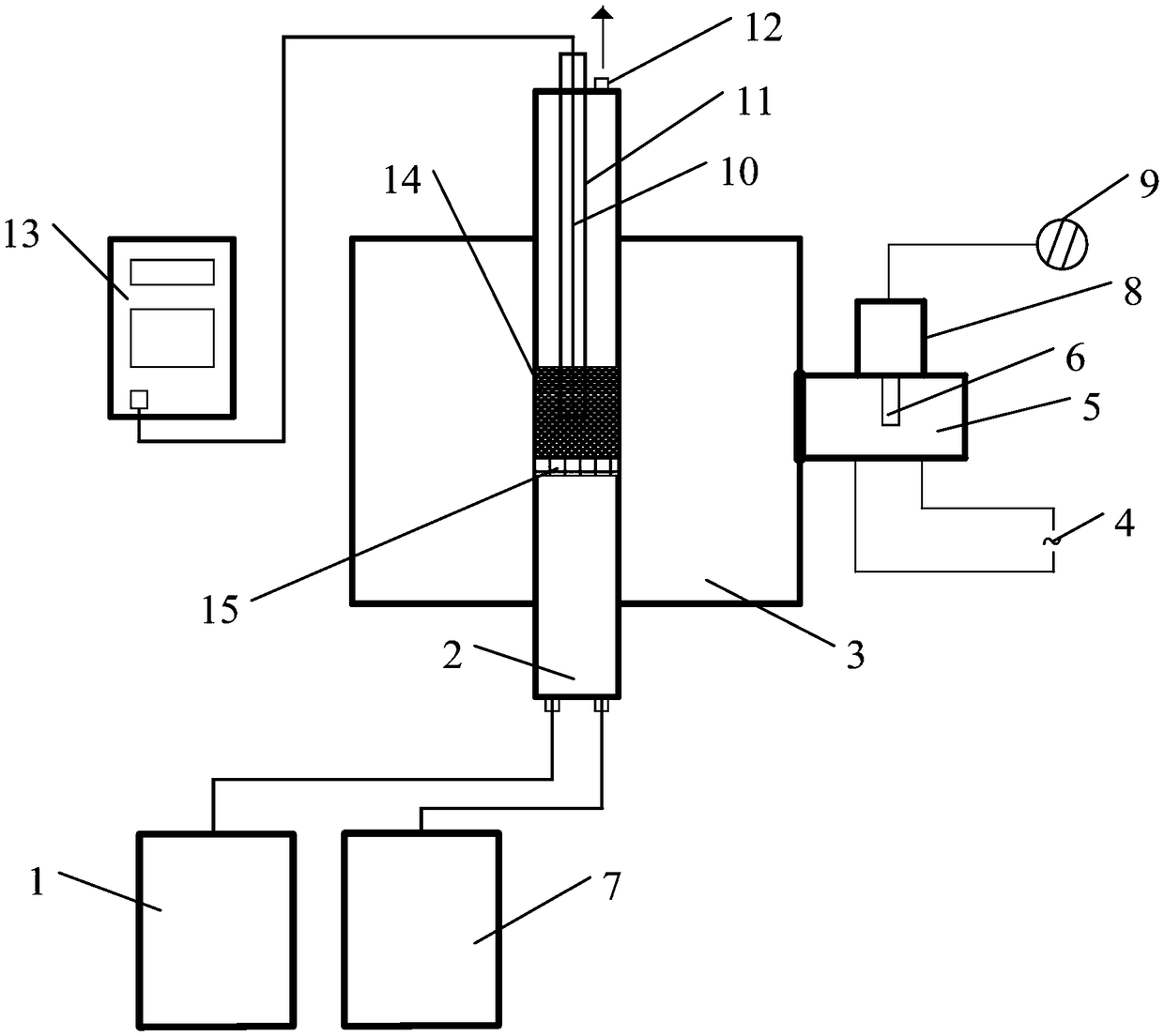

[0045] The structure of microwave fluidized roasting furnace is as follows: figure 1As shown, it includes a reaction chamber (2) and a microwave cavity (3) that is enclosed within it. The reaction chamber (2) is a cylindrical shape with upper and lower ends closed, and a quartz mesh (15) is provided inside; a thermocouple (10) Insert from the top of the reaction chamber (2), there is a gap between the bottom of the thermocouple (10) and the quartz mesh (15); the bottom of the reaction chamber (2) is provided with a protective gas inlet and a reducing gas inlet , the top is provided with an exhaust port (12); the microwave cavity (3) is equipped with a microwave generating device outside, and the microwave generating device is composed of a waveguide (5), a magnetron (8) and an antenna cap (6), and the waveguide (5 ) is connected to the power supply (4), the waveguide (5) is equipped with a magnetron (8), the magnetron (8) is equipped with a microwave power meter (9), and the a...

Embodiment 2

[0054] The device that adopts is with embodiment 1;

[0055] Method is with embodiment 1, and difference is:

[0056] (1) the iron grade of high-phosphorus oolitic hematite is 45%, and the mass percentage of phosphorus is 0.8%;

[0057] (2) Grinding the ore until the part with a particle size≤0.074mm accounts for 80% of the total mass to obtain iron ore powder;

[0058] (3) Heating to a reaction temperature of 570° C. under reducing atmosphere conditions, and roasting for 6 minutes; the reducing gas accounts for 20% of the total volume of the mixed gas; the reducing gas is H 2 ;

[0059] (4) Grinding the roasted ore until the particle size is ≤0.038mm accounts for 75% of the total mass, and the magnetic field strength of the weak magnetic separation is 82kA / m;

[0060] (5) The sulfuric acid concentration used during acid leaching dephosphorization is 0.25mol / L, the liquid-solid ratio of sulfuric acid and magnetic separation iron ore concentrate is 2mL / g, and the time of aci...

Embodiment 3

[0063] The device that adopts is with embodiment 1;

[0064] Method is with embodiment 1, and difference is:

[0065] (1) The iron grade of high-phosphorus oolitic hematite is 46%, and the mass percentage of phosphorus is 0.9%;

[0066] (2) Grinding the ore until the part with a particle size≤0.074mm accounts for 90% of the total mass to obtain iron ore powder;

[0067] (3) heating to reaction temperature 550 DEG C under reducing atmosphere conditions, roasting 8mi; reducing gas accounts for 25% of the total volume of mixed gas; described reducing gas is H 2 ;

[0068] (4) Grinding the roasted ore until the particle size is ≤0.038mm accounts for 80% of the total mass, and the magnetic field strength of the weak magnetic separation is 83kA / m;

[0069] (5) The sulfuric acid concentration used during acid leaching dephosphorization is 0.3mol / L, the liquid-solid ratio of sulfuric acid and magnetic iron concentrate is 4mL / g, and the time for acid leaching dephosphorization is 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com